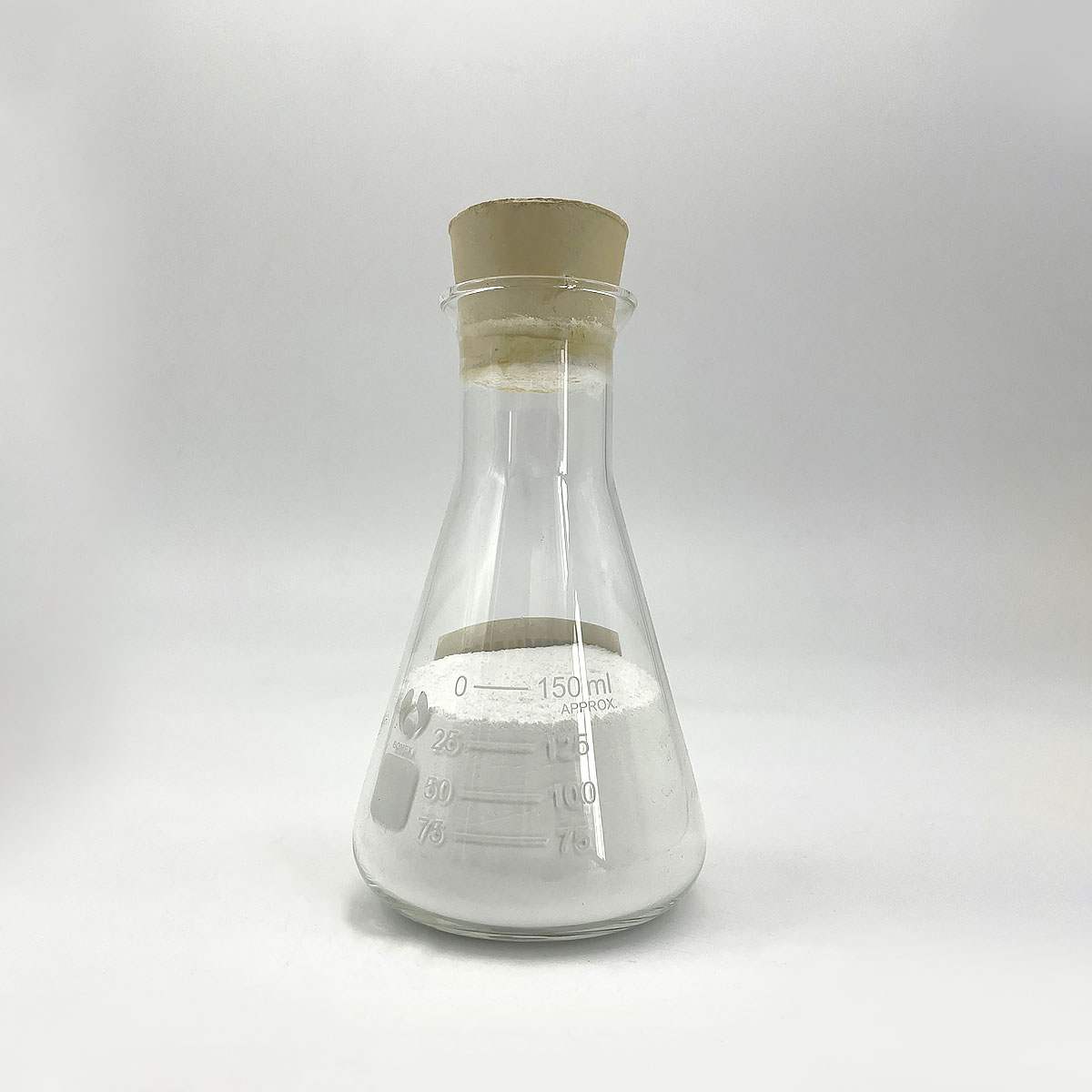

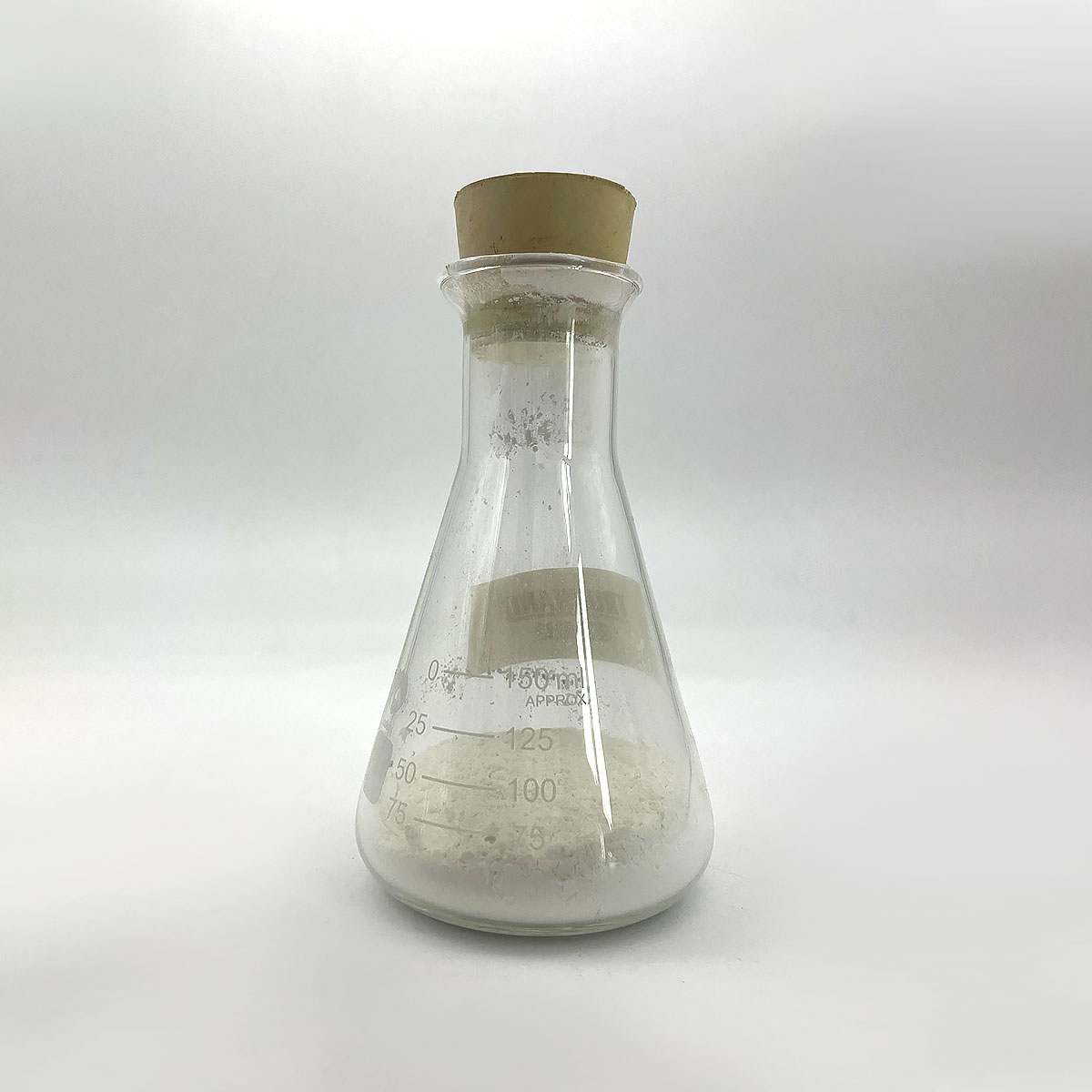

Overview of Tungsten carbide Thermal spraying powder/Cobalt Coated/Thermal Spray WC Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Tungsten carbide Thermal spraying powder/Cobalt Coated/Thermal Spray WC Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Tungsten carbide Thermal spraying powder/Cobalt Coated/Thermal Spray WC Powder)

Parameters of Tungsten carbide Thermal spraying powder/Cobalt Coated/Thermal Spray WC Powder

Tungsten carbide (WC) thermal spraying powder, also known as cobalt-coated tungsten carbide, is a high-performance material that finds extensive applications in various industries due to its exceptional wear resistance, hardness, and thermal stability. This advanced coating process imparts unique characteristics to the WC particles, making them ideal for, erosion-resistant, and high-temperature environments.

The manufacturing of thermal spray WC powder begins with the selection of pure tungsten carbide as the base material. Tungsten carbide is a compound of tungsten and carbon, with a chemical formula of WC. It is renowned for its extraordinary hardness, second only to diamond, and excellent thermal conductivity. The powder is then processed to achieve a specific particle size distribution, typically ranging from 45 microns to 100 microns, to ensure optimal adhesion and coverage during thermal spraying.

Cobalt coating is often applied to enhance the bonding between the tungsten carbide particles and the substrate. Cobalt, being a ductile binder, promotes better metallurgical bonding during the thermal spraying process. The cobalt layer also improves thermal stability, reducing the risk of spalling or delamination under elevated temperatures. The ratio of cobalt to tungsten carbide can vary, typically ranging from 5% to 20%, depending on the desired properties and application requirements.

The preparation of the thermal spray WC powder involves various stages, including, sieving, ball milling, and sometimes sintering. These processes ensure uniform particle size, shape, and surface roughness, which are crucial for achieving a consistent and durable coating. Additionally, the powder may undergo heat treatment to further refine its microstructure and enhance its mechanical properties.

During the thermal spraying process, the WC powder is accelerated by a high-velocity gas stream and transferred to the substrate, where it melts and solidifies upon impact. This rapid cooling results in a hard, dense, and wear-resistant coating. The thickness and quality of the coating depend on factors such as spray distance, angle, and powder flow rate, which need to be carefully controlled for optimal results.

Thermal sprayed tungsten carbide coatings are widely used in industries like aerospace, automotive, mining, and power generation. Applications include wear-resistant linings, cutting tools, valves, and bearings, where extreme conditions demand exceptional durability and resistance to wear and corrosion. The combination of tungsten carbide’s inherent strength and cobalt’s enhanced bonding capabilities makes this material an indispensable choice in these demanding environments.

In conclusion, tungsten carbide thermal spraying powder, particularly when coated with cobalt, is a technologically advanced material that offers superior performance in various industrial applications. Its unique properties, manufacturing process, and versatility make it a preferred choice for enhancing the durability and longevity of components operating under harsh conditions. As technology advances, researchers continue to explore ways to optimize the composition and application techniques to further improve the performance of this remarkable material.

(Tungsten carbide Thermal spraying powder/Cobalt Coated/Thermal Spray WC Powder)

FAQs of Tungsten carbide Thermal spraying powder/Cobalt Coated/Thermal Spray WC Powder

Inquiry us