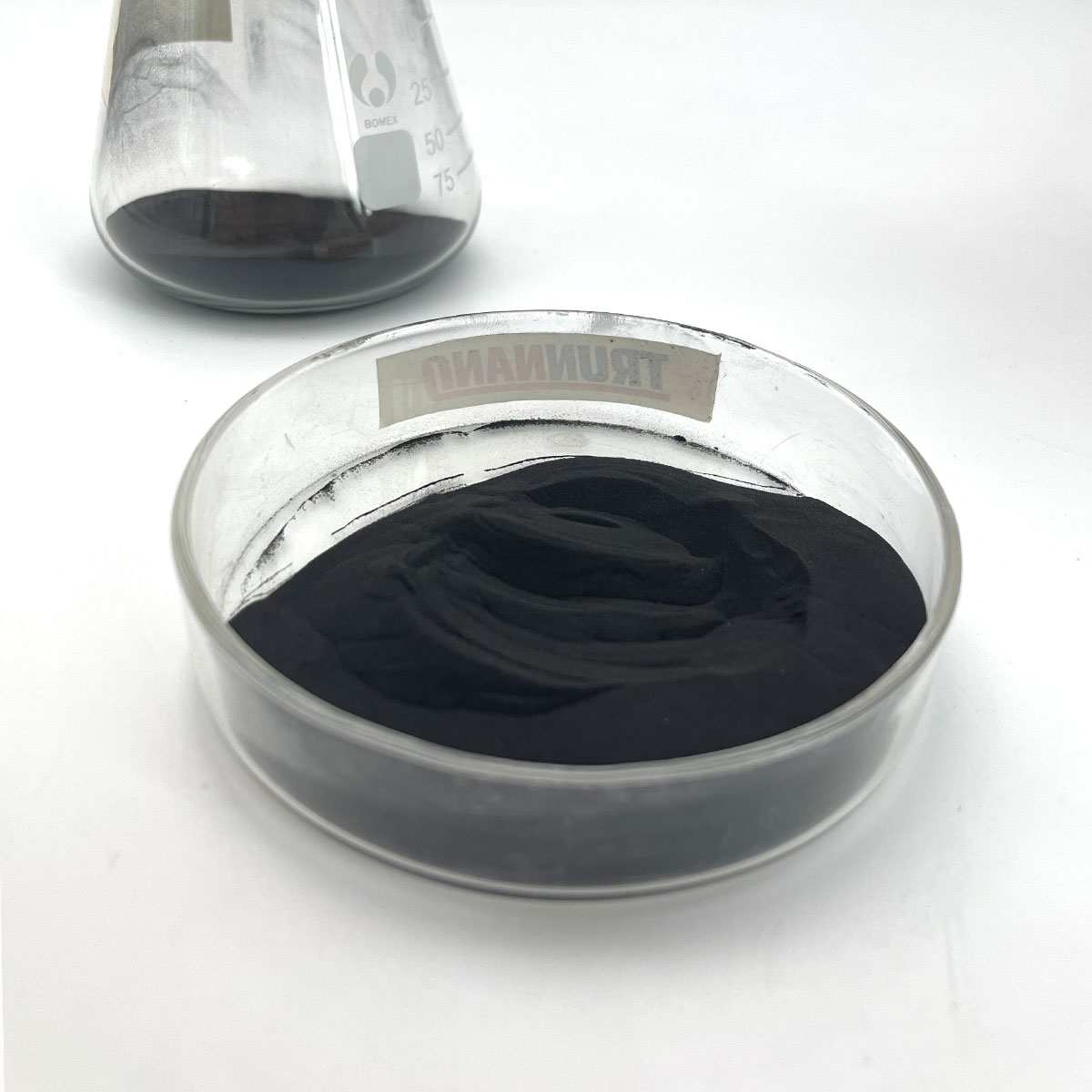

Overview of original virgin WC alloy powder grain size range from 10um to 100um pure Tungsten carbide powder and grits

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of original virgin WC alloy powder grain size range from 10um to 100um pure Tungsten carbide powder and grits

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(original virgin WC alloy powder grain size range from 10um to 100um pure Tungsten carbide powder and grits)

Parameters of original virgin WC alloy powder grain size range from 10um to 100um pure Tungsten carbide powder and grits

The original Virgin WC (Tungsten Carbide) alloy powder, known for its exceptional hardness and wear resistance, boasts a diverse grain size distribution that plays a crucial role in determining its mechanical properties and application suitability. The grain size range of this high-quality powder typically falls between 10 micrometers (μm) and 100 μm.

This narrow particle size spectrum allows for precise control over the material’s characteristics. The smaller particles, within the 10-30 μm range, offer a higher surface area, which enhances the bonding strength when sintered, leading to better density and improved wear resistance. These fine particles are often used in applications where high precision and surface finish are essential, such as cutting tools, wear-resistant coatings, and dental implants.

On the other hand, the larger particles, around 50-100 μm, provide better handling and flowability during processing, making them suitable for applications that require casting or pressing techniques. They also contribute to a more consistent microstructure during heat treatment, resulting in improved mechanical properties like toughness and fatigue resistance.

The purity of the tungsten carbide powder is another critical aspect, as impurities can affect the overall performance. A high-purity grade ensures minimal contamination, resulting in superior wear resistance and chemical stability. The absence of any additives or contaminants contributes to the longevity and reliability of the final product.

In addition to grain size and purity, the WC powder’s morphology, which refers to its shape and crystal structure, is also significant. It is commonly found in various forms, such as spherical, irregular, or submicron, each with its own advantages. Spherical particles promote uniform flow and better densification during sintering, while irregular shapes may offer better mechanical interlocking, leading to enhanced strength.

To maintain the quality and consistency of the powder, strict quality control measures are implemented throughout the production process, ensuring that the particle size distribution, purity, and morphology meet industry standards. This attention to detail is vital for consistently delivering high-performance tungsten carbide products across different industries, from aerospace to automotive to manufacturing.

In conclusion, the original Virgin WC alloy powder with a grain size range of 10-100 μm is a premium material that offers a balance of strength, wear resistance, and processability. Its purity, along with the careful control of particle size and morphology, makes it an ideal choice for a wide range of demanding applications where durability and precision are paramount. By understanding these key parameters, engineers and manufacturers can optimize their processes and achieve optimal performance from tungsten carbide-based components.

(original virgin WC alloy powder grain size range from 10um to 100um pure Tungsten carbide powder and grits)

FAQs of original virgin WC alloy powder grain size range from 10um to 100um pure Tungsten carbide powder and grits

Inquiry us