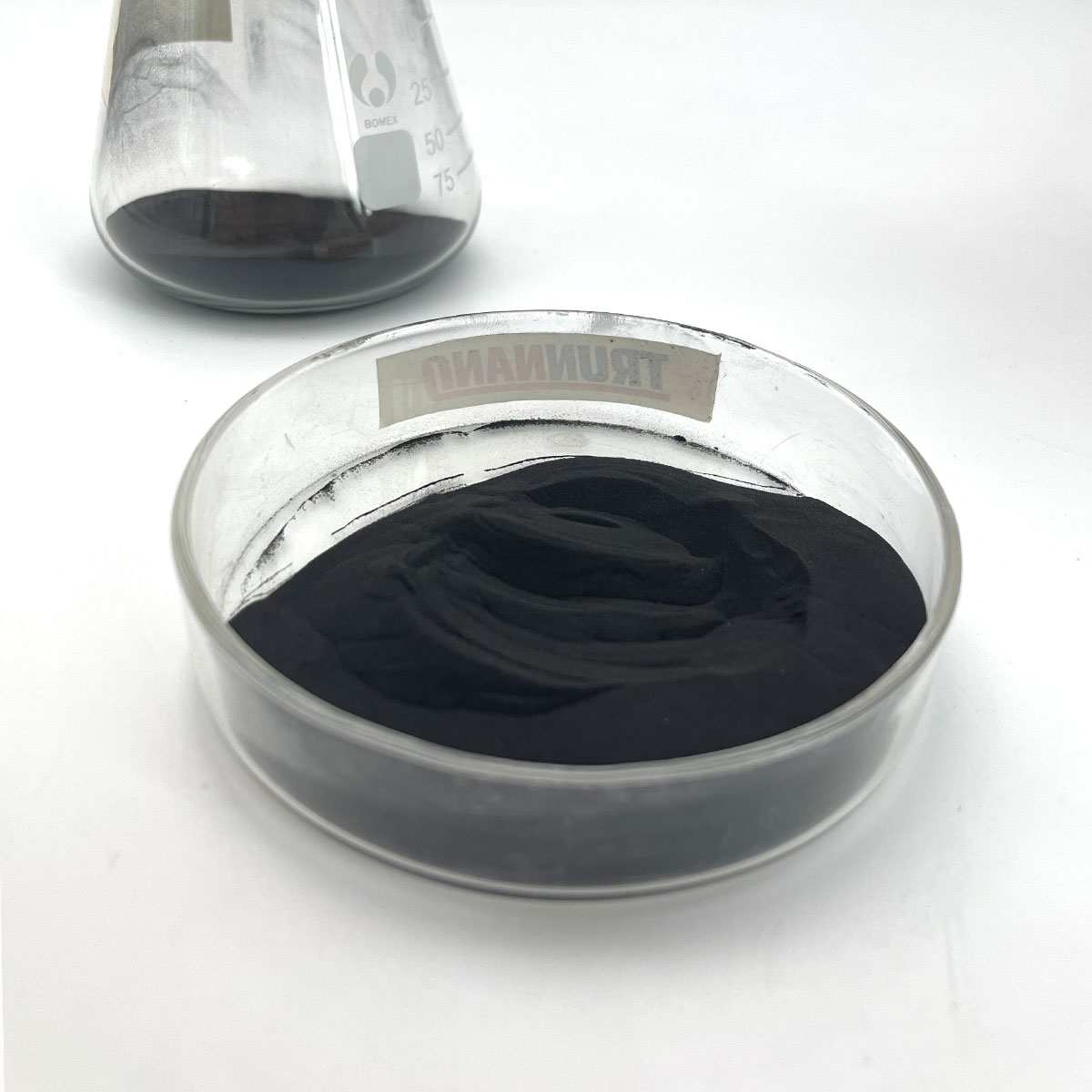

Overview of Thermal spraying powder WC Powder Tungsten carbide Granules

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Thermal spraying powder WC Powder Tungsten carbide Granules

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Thermal spraying powder WC Powder Tungsten carbide Granules)

Parameters of Thermal spraying powder WC Powder Tungsten carbide Granules

Thermal spraying is a high-temperature deposition process used to apply a wide variety of materials, including tungsten carbide (WC), onto surfaces to enhance their wear resistance, hardness, and other mechanical properties. WC powder, specifically, is a popular choice due to its exceptional strength and ability to withstand extreme conditions. Here’s an overview of tungsten carbide thermal spray powder parameters in a detailed format:

1. Composition: WC thermal spray powder primarily consists of tungsten (W) and carbon (C) in the form of carbide. The typical composition ranges from 90% tungsten to 97% tungsten with the remaining percentage being carbon, usually around 3% to 5%. This balance ensures the desired hardness, wear resistance, and machinability.

2. Particle size distribution: The particle size plays a crucial role in the coating’s performance. WC powders are available in various granule sizes, typically ranging from 45 microns to 125 microns, although some specialized formulations may have smaller or larger particles. A narrow particle size distribution ensures better adhesion and coating density during the spraying process.

3. Shape and morphology: WC powder particles are generally spherical or irregular in shape, with a smooth surface that promotes adhesion to the substrate. The particle morphology influences the coating’s porosity and mechanical properties. Proper particle shape ensures a more consistent and dense deposit.

4. Purity: High purity WC powders are essential for achieving optimal performance. Impurities like cobalt, vanadium, or molybdenum can be present in trace amounts, but they must be controlled to maintain the desired chemical stability and properties.

5. Hardness and wear resistance: WC thermal spray coatings exhibit a Vickers hardness of around 2800 HV to 3200 HV, making them extremely hard and resistant to wear. This is due to the strong carbon-bonded tungsten structure, which resists deformation under heavy loads.

6. Thermal stability: Tungsten carbide is inherently thermally stable, allowing it to maintain its properties even at elevated temperatures. This makes it suitable for applications where heat resistance is critical, such as in gas turbines or industrial furnaces.

7. Coating thickness: The achievable coating thickness depends on the spraying technique and process parameters. Generally, WC coatings range from 0.1mm to 3mm, providing a balance between wear resistance and surface integrity.

8. Bonding strength: A good bond between the WC particles and the substrate is vital for the coating’s durability. WC thermal sprayed coatings can achieve strong mechanical interlocking and metallurgical bonding, contributing to the overall strength of the coating.

9. Compatibility: WC powder is compatible with various thermal spraying techniques, including plasma, arc, and oxy-fuel processes. The choice of process depends on the application’s requirements, substrate material, and cost considerations.

10. Post-processing: After thermal spraying, the coating may require post-processing, such as annealing, to optimize its microstructure and mechanical properties. This step helps to reduce internal stresses and improve wear resistance.

In conclusion, tungsten carbide (WC) thermal spray powder is characterized by its high hardness, wear resistance, and thermal stability. Its performance relies on factors like particle size, purity, and the spraying process used. By carefully selecting and optimizing these parameters, WC thermal spray coatings can significantly enhance the durability and functionality of various components across industries.

(Thermal spraying powder WC Powder Tungsten carbide Granules)

FAQs of Thermal spraying powder WC Powder Tungsten carbide Granules

Inquiry us