Overview of MSDS Certification 200g/Bags Titanium Metal Powder For Cold Sparkler Powder Fountain Fireworks Spark Machine Consumables

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of MSDS Certification 200g/Bags Titanium Metal Powder For Cold Sparkler Powder Fountain Fireworks Spark Machine Consumables

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(MSDS Certification 200g/Bags Titanium Metal Powder For Cold Sparkler Powder Fountain Fireworks Spark Machine Consumables)

Parameters of MSDS Certification 200g/Bags Titanium Metal Powder For Cold Sparkler Powder Fountain Fireworks Spark Machine Consumables

Title: Material Safety Data Sheet (MSDS) for 200g Bags of Titanium Metal Powder for Cold Sparkler Powders and Fountain Fireworks Spark Machines Consumables

1. Identification

Product Name: Titanium Metal Powder

Trade Name: Cold Sparkler Powder or Fireworks Fountain Spark Machine Consumables

Product Number: [Insert Product Number]

Batch Number: [Insert Batch Number]

Supplier: [Insert Company Name]

Address: [Insert Company Address]

2. Hazardous Ingredients

Titanium metal powder is primarily composed of titanium dioxide (TiO2), which is the main ingredient. It may contain trace amounts of impurities, such as iron oxide, carbon, or silicon dioxide, which are considered non-hazardous at the recommended concentrations.

3. Composition:

– Titanium Dioxide (TiO2): ≥98%

– Impurities (if any): Iron Oxide, Carbon, Silicon Dioxide (trace amounts)

4. Physical and Chemical Properties

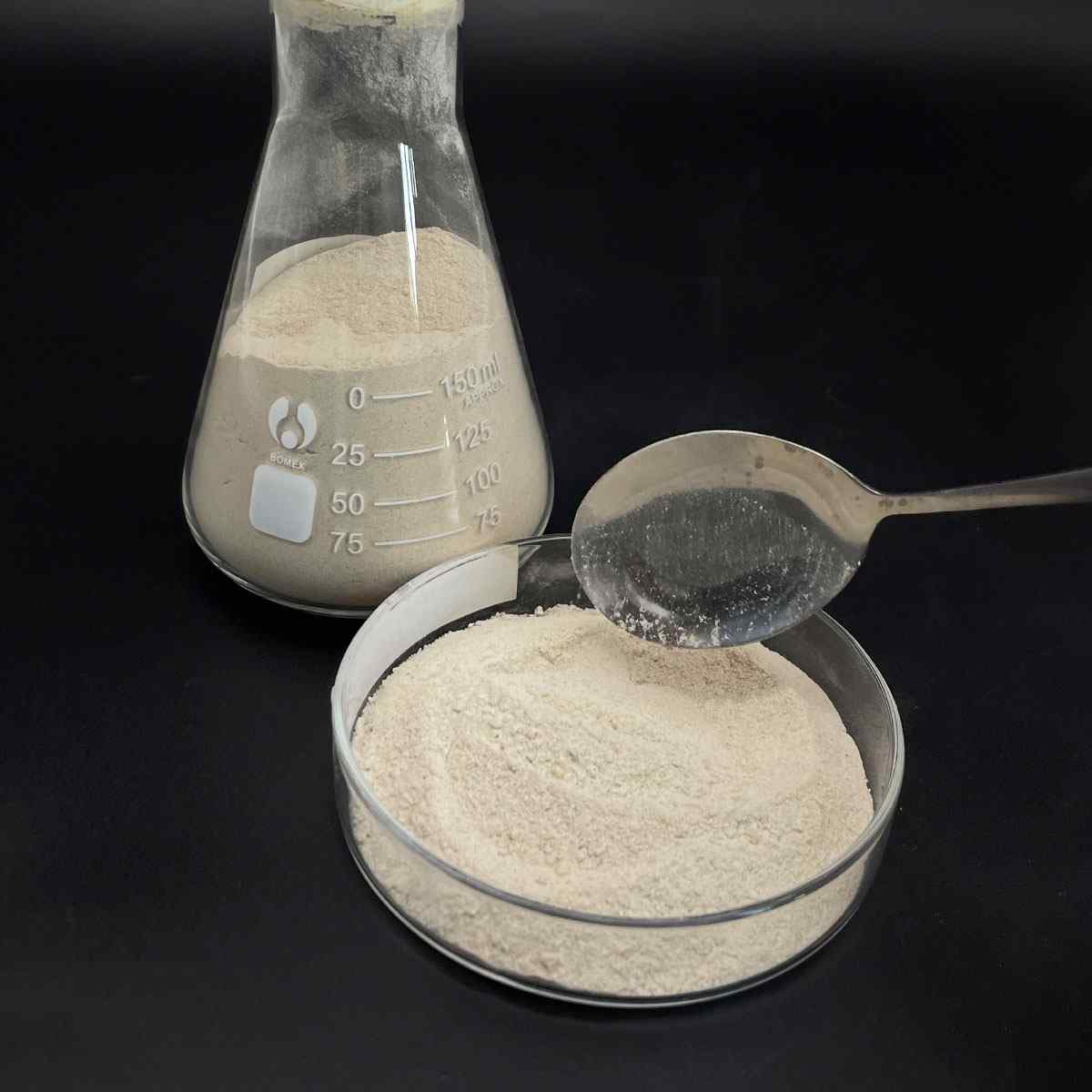

– Appearance: White to grayish powder

– Particle Size: Fine, typically 50-100 mesh (0.149 – 0.074 mm)

– Melting Point: 1668°C (3034°F)

– Ignition Temperature: Cold sparklers – below 300°C (572°F); Fireworks fountain sparks – varies depending on ignition source

– Solubility: Insoluble in water

– Stability: Stable under normal conditions; may react with oxidizers or acids

5. Health Hazards

– Inhalation: Inhalation of fine particles may cause irritation to the respiratory system, especially if inhaled deeply. Avoid prolonged exposure.

– Skin Contact: Non-corrosive, but may cause skin irritation if not handled properly. Wash affected area immediately with soap and water.

– Eye Contact: May cause temporary irritation. Rinse thoroughly with water.

6. Fire and Explosion Hazards

– Fire: Not flammable in its pure form. However, when mixed with combustible materials, ignition may occur.

– Explosion: Can create sparks, which may ignite nearby flammable substances. Follow proper handling and storage procedures.

7. Handling and Storage

– Store in a cool, dry, and well-ventilated area away from heat, flames, and oxidizing agents.

– Use approved containers with tight-fitting lids to prevent accidental release.

– Do not store near incompatible materials or foodstuffs.

8. Personal Protective Equipment (PPE)

– Eye protection: Safety glasses or goggles

– Respiratory protection: Use a dust mask if prolonged exposure is anticipated

– Gloves: Latex or nitrile gloves to minimize skin contact

9. Emergency Procedures

– If swallowed: Drink plenty of water and seek medical attention immediately.

– If inhaled: Remove person to fresh air and provide medical attention if needed.

– Fire: Use a CO2 extinguisher or water spray, but avoid water if metal powders are involved.

10. Disposal

– Dispose of according to local regulations and guidelines for chemical waste.

– Do not pour down drains or sewers.

This MSDS provides general information and should be used in conjunction with proper training and adherence to all safety protocols. Keep this document accessible to all users and ensure compliance with applicable laws and regulations.

[Company Name]

[Date]

(MSDS Certification 200g/Bags Titanium Metal Powder For Cold Sparkler Powder Fountain Fireworks Spark Machine Consumables)

FAQs of MSDS Certification 200g/Bags Titanium Metal Powder For Cold Sparkler Powder Fountain Fireworks Spark Machine Consumables

Inquiry us