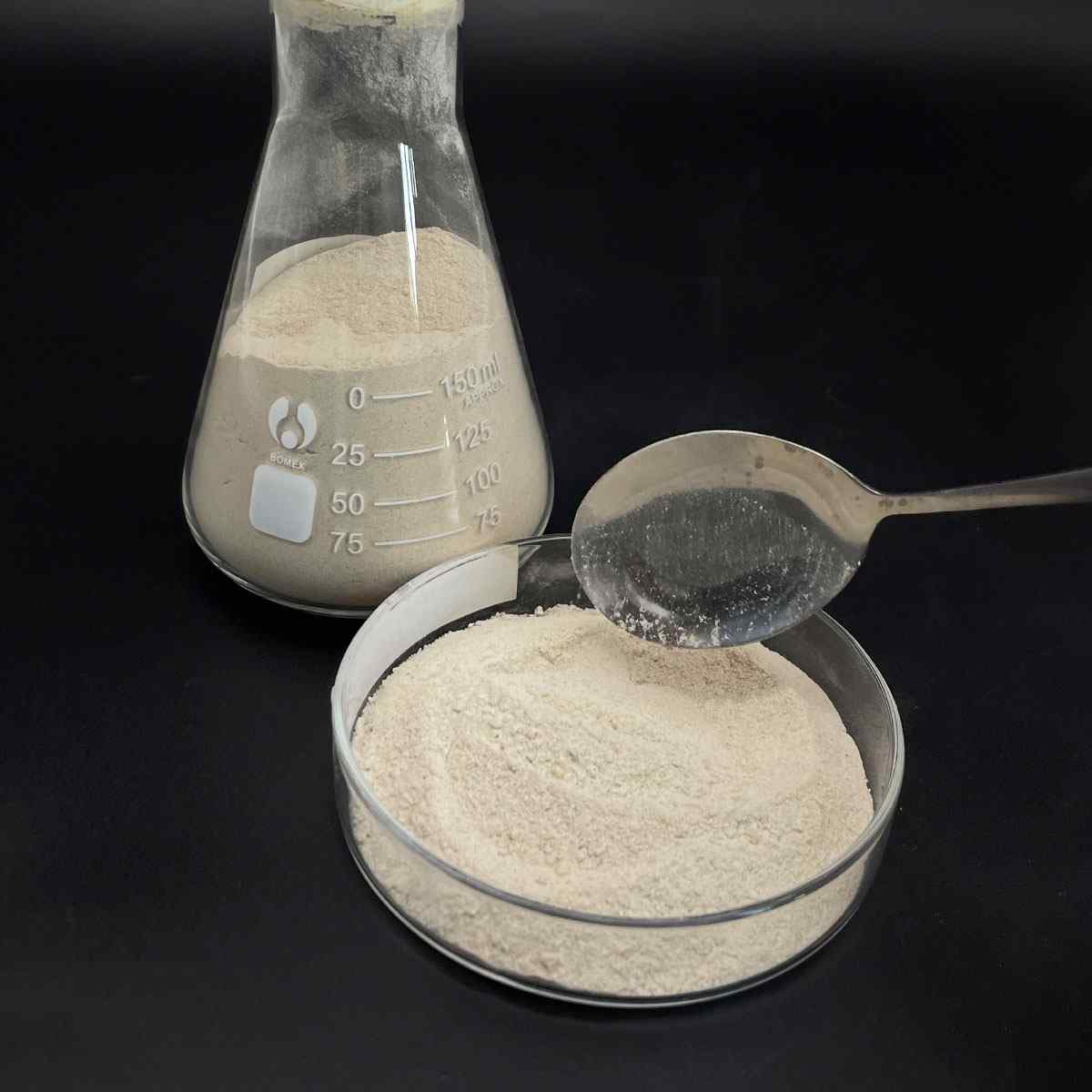

Overview of Industry Pure Nanoparticles Tio2 Powder Titanium Dioxide Rutile Grade 6618

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Industry Pure Nanoparticles Tio2 Powder Titanium Dioxide Rutile Grade 6618

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Industry Pure Nanoparticles Tio2 Powder Titanium Dioxide Rutile Grade 6618)

Parameters of Industry Pure Nanoparticles Tio2 Powder Titanium Dioxide Rutile Grade 6618

Title: Comprehensive Overview of High-Quality Rutile TiO2 Nanoparticles (Grade 6618) for Industry Applications

Introduction:

Titanium dioxide, commonly known as TiO2, is a versatile and widely used inorganic compound due to its exceptional properties, particularly in the form of nanoparticles. Among various forms, rutile-grade TiO2 is highly sought after for its unique characteristics, such as high purity, anatase-to-rutile ratio, and excellent photocatalytic performance. This article delves into the key parameters of industry-grade rutile TiO2 powder (Grade 6618), providing essential information for manufacturers and researchers seeking to incorporate this material into their applications.

Purity:

One of the primary factors that distinguish Grade 6618 TiO2 is its exceptional purity. With a minimum purity level of 99.5%, this grade ensures a high degree of chemical stability, reducing impurities that could potentially affect the performance or reliability of the final product. The purity contributes to better light absorption, enhanced photocatalytic efficiency, and improved durability in various industrial processes.

Particle Size and Distribution:

The particles in Grade 6618 TiO2 are carefully controlled to have a narrow size distribution, typically ranging from 20 to 30 nanometers. This uniformity ensures consistent performance across different applications and minimizes agglomeration issues, which can hinder the desired surface area and reactivity. The small particle size also plays a crucial role in enhancing the photocatalytic activity and light scattering properties.

Crystal Structure:

Rutile TiO2 (Grade 6618) is characterized by a tetragonal crystal structure, which is known for its robustness and stability under various conditions. The rutile phase offers higher thermal stability compared to other forms like anatase, making it suitable for applications that require resistance to high temperatures. The high crystallinity of this grade ensures minimal defects, contributing to improved photocatalytic efficiency.

Surface Area and Porosity:

Grade 6618 TiO2 boasts a relatively high specific surface area, typically in the range of 50-80 m²/g. This increased surface area allows for more efficient adsorption of reactants and catalysts, enhancing the overall reaction rate and performance in applications like photocatalytic degradation, self-cleaning coatings, and solar cells. The porosity further enhances the accessibility of active sites, promoting effective catalytic reactions.

Optical Properties:

Rutile TiO2 (Grade 6618) exhibits strong light absorption in the UV region, which is vital for various photocatalytic processes. Its bandgap energy, around 3.04 eV, makes it ideal for capturing sunlight and converting it into chemical energy. This feature is particularly beneficial for applications where harnessing solar energy is crucial, such as water purification, air purification, and organic pollutant degradation.

Application-Specific Parameters:

Grade 6618 TiO2 finds extensive use in various industries, including:

1. Paints and Coatings: Its high refractive index and opacity make it a popular choice for self-cleaning, anti-UV, and antimicrobial coatings.

2. Photovoltaics: Rutile TiO2 acts as a transparent conductive layer in thin film solar cells, improving efficiency and cost-effectiveness.

3. Electronics: Used in inkjet printing and display technologies, offering excellent electrical conductivity and stability.

4. Environmental Remediation: Its photocatalytic properties are employed in air and water purification systems to degrade pollutants.

5. Cosmetics: Acts as a sunscreen agent due to its UV-blocking capabilities.

Conclusion:

Grade 6618 rutile TiO2 nanoparticles are a premium choice for industry applications due to their high purity, controlled particle size, and unique crystal structure. These properties contribute to superior performance in various sectors, from solar energy conversion to environmental protection. Understanding these parameters is essential for engineers and scientists looking to harness the full potential of this versatile material.

(Industry Pure Nanoparticles Tio2 Powder Titanium Dioxide Rutile Grade 6618)

FAQs of Industry Pure Nanoparticles Tio2 Powder Titanium Dioxide Rutile Grade 6618

Inquiry us