Overview of MOLYBDENUM TRIOXIDE

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of MOLYBDENUM TRIOXIDE

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(MOLYBDENUM TRIOXIDE)

Parameters of MOLYBDENUM TRIOXIDE

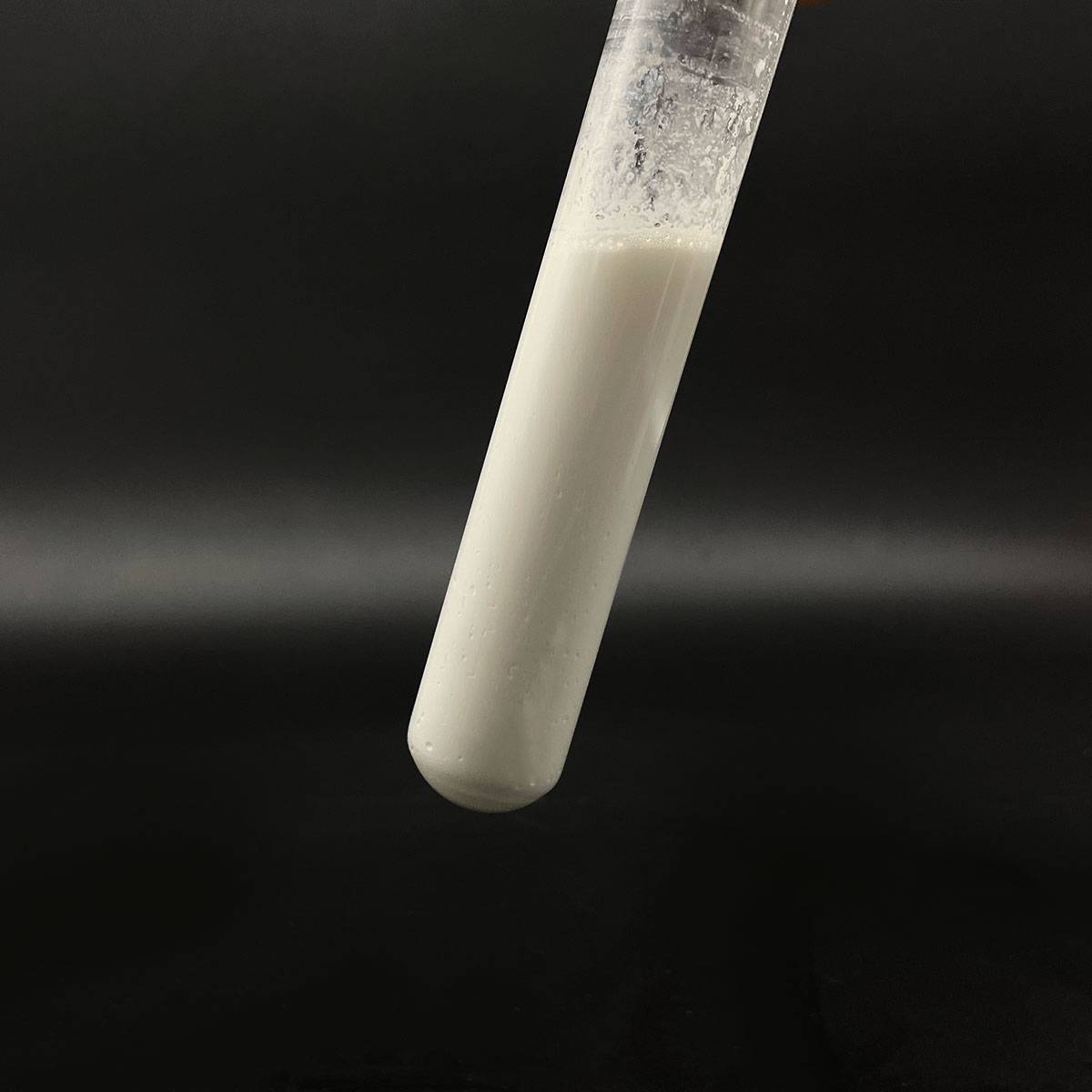

Molybdenum trioxide, also known as MoO3, is an inorganic compound that plays a significant role in various industrial applications due to its unique properties. It is primarily composed of molybdenum (Mo), a transition metal, and oxygen (O), forming a chemical bond characterized by its high oxidation state of +6 for molybdenum. The compound exists as a white or yellowish crystalline solid, which can be amorphous or powdery in appearance depending on its preparation method.

Molybdenum trioxide is formed through the reaction of molybdenum with oxygen, often under high temperatures, such as during the roasting process of molybdenite, the most common ore of molybdenum. The compound is thermodynamically stable and resistant to decomposition at room temperature, but it can decompose upon exposure to extreme heat or reducing conditions.

One of the key features of molybdenum trioxide is its ability to act as a catalyst in numerous chemical reactions. It is widely used in the petrochemical industry as a catalyst for hydrodesulfurization processes, where it helps remove sulfur compounds from crude oil, making it suitable for cleaner-burning fuels. Additionally, in the refining of crude metals like tungsten and tantalum, MoO3 serves as a getter, removing impurities and improving the purity of the final product.

In the field of electronics, molybdenum trioxide finds application in thin film technologies, particularly as a transparent conducting oxide (TCO). TCOs, like MoO3, are essential components in solar cells, touchscreens, and displays, providing both electrical conductivity and optical transparency. The compound’s high work function allows it to efficiently conduct electricity while maintaining a low electron density, which is crucial for efficient energy transfer.

Another area where molybdenum trioxide is employed is in the production of refractory materials. Its high melting point (around 2,800°C) and excellent thermal stability make it ideal for use in high-temperature applications, such as furnace linings, crucibles, and ceramic coatings. These materials withstand intense heat and protect other components from degradation.

Environmental remediation is another growing area where molybdenum trioxide is utilized. It can act as a sorbent, absorbing heavy metals and toxic substances, making it useful in treating contaminated soils and water. Its ability to selectively bind and immobilize contaminants makes it a promising material for pollution control.

In the field of chemistry, molybdenum trioxide is a versatile reagent in various redox reactions. It can participate in redox titrations, as well as in the synthesis of other molybdenum compounds. Moreover, its catalytic activity in organic reactions has been investigated, though not as extensively as in inorganic systems.

In summary, molybdenum trioxide is a multifaceted compound with a wide range of applications due to its exceptional properties. Its catalytic prowess, thermal stability, and electronic conductivity make it an essential material in industries ranging from petrochemicals to electronics, while its environmental remediation potential offers a promising avenue for future research. As researchers continue to explore its properties, molybdenum trioxide is poised to play an increasingly important role in various technological advancements.

(MOLYBDENUM TRIOXIDE)

FAQs of MOLYBDENUM TRIOXIDE

Inquiry us