Overview of Amino Acid Chelate Iron/Copper/ Manganese/Zinc/Boron/Molybdenum Compound Foliar Fertilizer(flow powder fertilizer)

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Amino Acid Chelate Iron/Copper/ Manganese/Zinc/Boron/Molybdenum Compound Foliar Fertilizer(flow powder fertilizer)

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Amino Acid Chelate Iron/Copper/ Manganese/Zinc/Boron/Molybdenum Compound Foliar Fertilizer(flow powder fertilizer))

Parameters of Amino Acid Chelate Iron/Copper/ Manganese/Zinc/Boron/Molybdenum Compound Foliar Fertilizer(flow powder fertilizer)

Amino Acid Chelate Iron/Copper/Manganese/Zinc/Boron/Molybdenum Compound Foliar Fertilizer: An Advanced Nutrient Solution for Optimal Plant Growth

In today’s dynamic agricultural landscape, foliar fertilizers have emerged as a powerful tool for enhancing plant productivity and overcoming nutrient deficiencies. One such advanced formulation is the amino acid chelate iron/copper/manganese/zinc/boron/molybdenum compound fertilizer, which offers a unique blend of essential micronutrients in a highly bioavailable form.

The primary component of this fertilizer is amino acid chelates, which are organic compounds that bind tightly to metal ions like iron, copper, manganese, zinc, boron, and molybdenum. Amino acids, being the building blocks of proteins, naturally occur in plants and act as carriers for these nutrients, making them easily absorbed and utilized by the plant’s roots. This chelation process improves nutrient uptake efficiency, reducing the risk of toxicity and ensuring plants receive the vital nutrients they need for optimal growth.

Iron, a crucial element for chlorophyll production and oxygen transportation, is often limiting in many soils. The amino acid chelate form ensures that iron is delivered directly to the plant’s leaves, improving its resistance to stress and enhancing photosynthesis.

Copper, another essential micronutrient, plays a vital role in enzyme function and the development of new leaves. The chelated copper in this fertilizer ensures that it reaches the right cellular compartments, preventing deficiency-related issues like yellowing and necrosis.

Manganese is involved in numerous metabolic processes, including the synthesis of chlorophyll and the regulation of enzymes. The amino acid chelate manganese provides a steady supply of this vital nutrient, supporting healthy plant growth and vigor.

Zinc, a cofactor for over 300 enzymes, is vital for root development and immune system function. The chelated zinc in this fertilizer ensures efficient uptake, enabling plants to maintain strong roots and withstand diseases.

Boron, though present in small amounts, is critical for pollen tube formation and fruit set. The amino acid chelate form of boron ensures plants receive adequate amounts without causing toxicity, promoting reproductive health and yield.

Lastly, molybdenum, involved in nitrogen metabolism, aids in detoxifying harmful compounds. The chelated molybdenum in this foliar fertilizer ensures that plants can utilize it effectively, promoting overall plant health and stress tolerance.

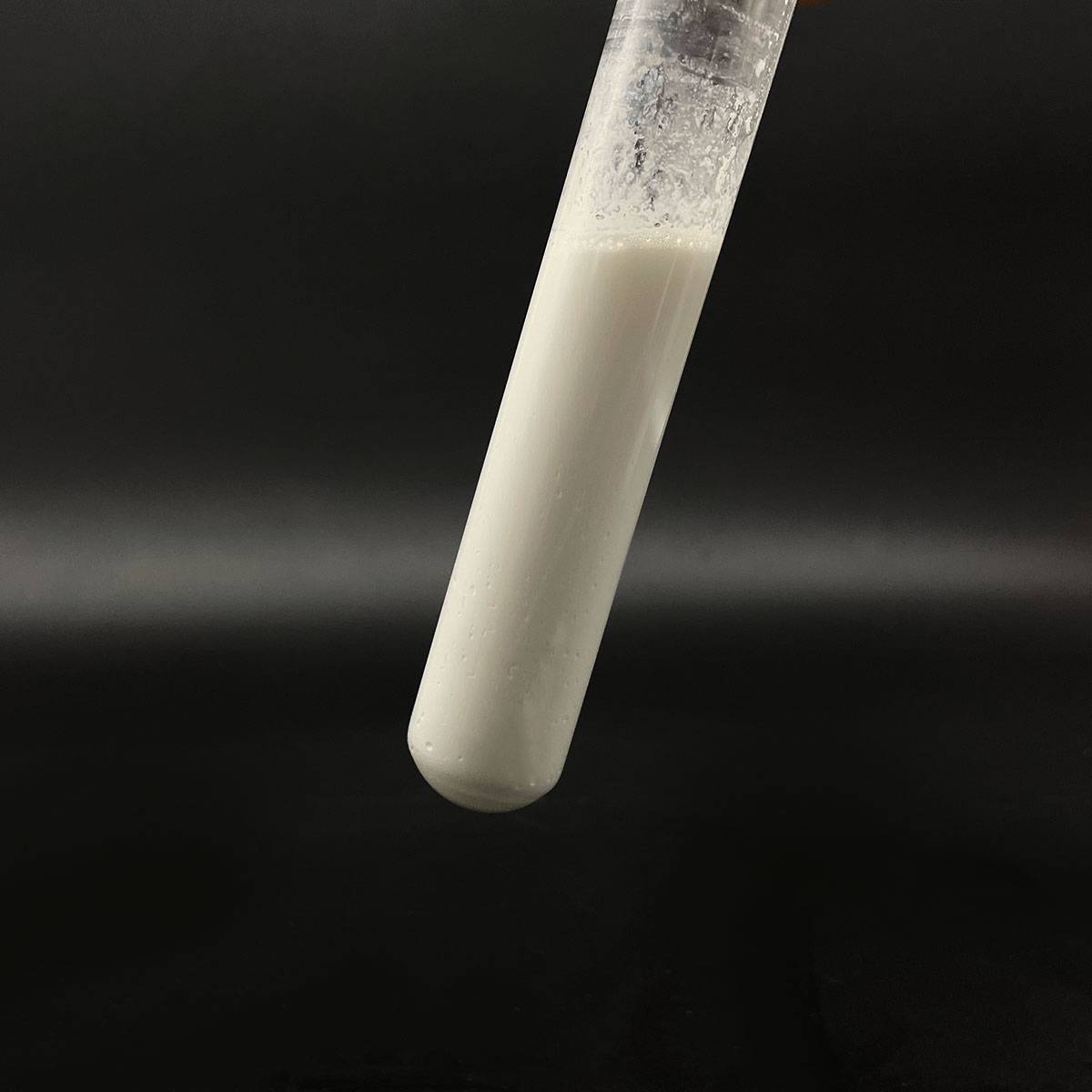

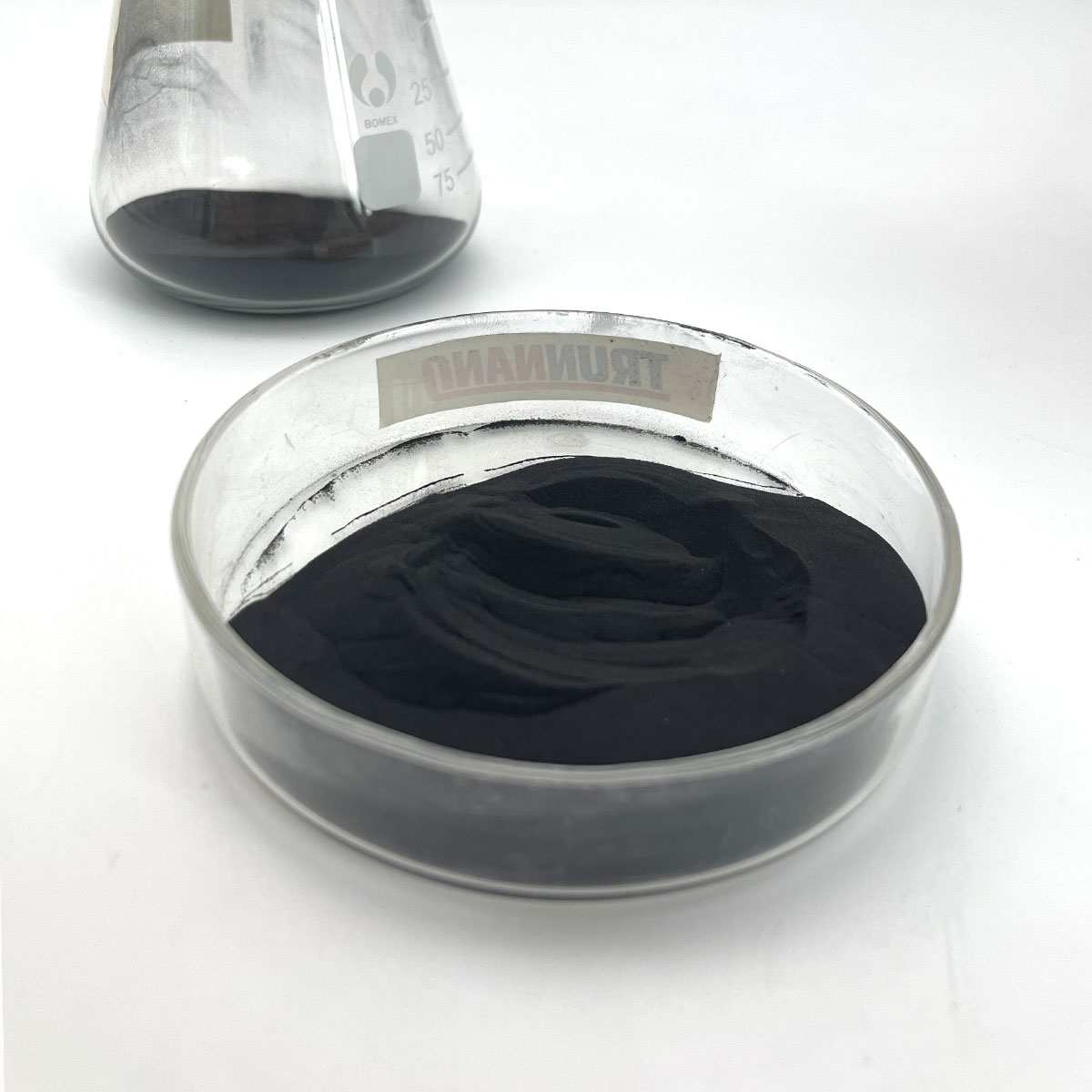

This compound foliar fertilizer is designed to be applied as a flow powder, allowing for easy and targeted application through irrigation systems or manual spraying. The fine particles ensure even distribution, reaching all parts of the plant, including those in the vegetative and reproductive stages, where micronutrient requirements are highest.

The use of amino acid chelate micronutrient complexes offers several advantages over traditional forms, including better nutrient retention, reduced leaching, and improved plant response. By providing a balanced and efficient delivery of these essential elements, this foliar fertilizer supports enhanced crop yields, improved quality, and a more sustainable agricultural practice.

In conclusion, the amino acid chelate iron/copper/manganese/zinc/boron/molybdenum compound foliar fertilizer is an innovative and effective solution for modern farmers seeking to optimize their plants’ nutrient status and overall health. Its unique formulation ensures that these vital micronutrients are readily available and efficiently utilized, contributing to a stronger, healthier, and more productive crop.

(Amino Acid Chelate Iron/Copper/ Manganese/Zinc/Boron/Molybdenum Compound Foliar Fertilizer(flow powder fertilizer))

FAQs of Amino Acid Chelate Iron/Copper/ Manganese/Zinc/Boron/Molybdenum Compound Foliar Fertilizer(flow powder fertilizer)

Inquiry us