Overview of Micro Coated Titanium Anode and Platinum Plated Titanium expanded Metal

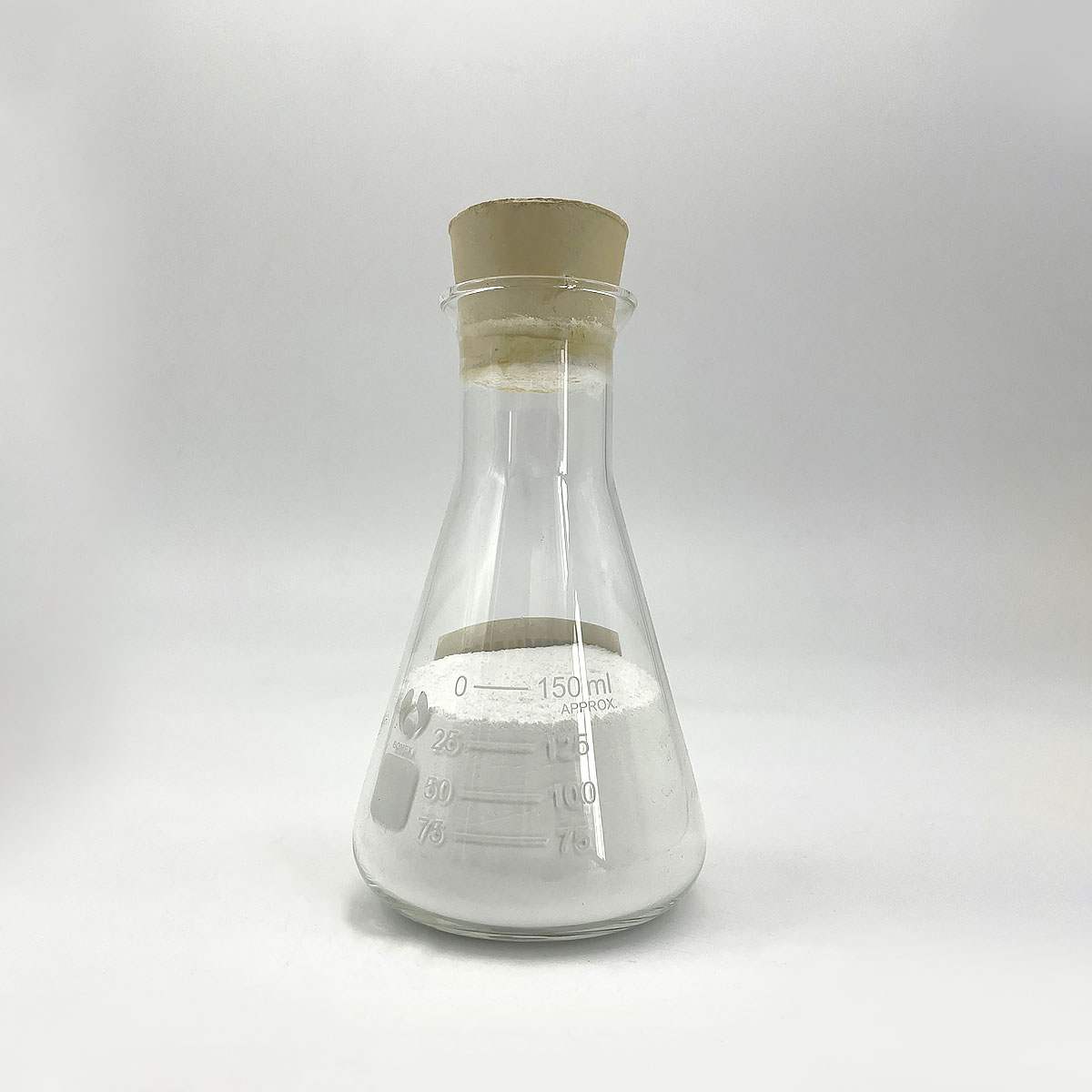

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Micro Coated Titanium Anode and Platinum Plated Titanium expanded Metal

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Micro Coated Titanium Anode and Platinum Plated Titanium expanded Metal)

Parameters of Micro Coated Titanium Anode and Platinum Plated Titanium expanded Metal

Micro-Coated Titanium Anodes and Platinum-Plated Titanium Expanded Metal: A Comprehensive Overview

In the realm of electrochemical processes, anodes play a vital role in facilitating the transfer of electrons, particularly in applications such as water treatment, metal refining, and corrosion protection. Two notable types of anodes that have gained significant attention in recent years are micro-coated titanium anodes and platinum-plated titanium expanded metal anodes. These materials offer unique properties that make them suitable for various industrial environments.

Micro-Coated Titanium Anodes:

Micro-coated titanium anodes are engineered by depositing a thin layer of titanium dioxide (TiO2) onto a high-purity titanium substrate. This coating process typically involves chemical vapor deposition (CVD) or physical vapor deposition (PVD). The microstructure of the coating results in a large surface area, which enhances its performance in terms of efficiency and durability.

The primary advantage of micro-coated titanium anodes is their excellent corrosion resistance. The TiO2 coating forms a protective barrier against corrosive electrolytes, prolonging the anode’s service life. Additionally, the microstructure promotes uniform current distribution, reducing hot spots and improving overall performance. These anodes are lightweight, easy to install, and have low electrical resistance, translating to lower energy consumption during operation.

Furthermore, the micro-coating technology allows for customization, enabling the addition of other materials like conductive polymers or nanoparticles for enhanced performance in specific applications. However, it’s worth noting that while titanium is naturally resistant to many environments, prolonged exposure to harsh conditions may require periodic maintenance.

Platinum-Plated Titanium Expanded Metal Anodes:

Platinum-plated titanium expanded metal, on the other hand, consists of a titanium base material that has been chemically or physically treated to form a thin layer of platinum. Expanded metal is created by stretching a solid sheet of titanium into a web-like structure, which increases its surface area and provides excellent mechanical strength.

The platinum coating imparts several advantages to this type of anode. Firstly, platinum’s inherent corrosion resistance significantly extends the anode’s lifetime, especially in chloride-rich environments. It also improves the anode’s ability to withstand high temperatures and offers superior performance in severe conditions. Platinum’s catalytic properties enhance the efficiency of the electrochemical reactions, leading to faster reaction rates and improved power output.

However, platinum-plated titanium expanded metal anodes are generally more expensive than their uncoated counterparts due to the cost of platinum. This makes them a premium option for applications where longevity and high performance are paramount, but not necessarily budget constraints.

In conclusion, both micro-coated titanium anodes and platinum-plated titanium expanded metal anodes excel in providing robust and efficient performance in electrochemical processes. Micro-coated anodes benefit from their enhanced corrosion resistance and customizable properties, while platinum-plated expanded metal offers exceptional durability and catalytic activity. The choice between the two ultimately depends on the specific application requirements, budget, and desired lifespan. As technology advances, these materials continue to evolve, promising even greater performance and adaptability in various industries.

(Micro Coated Titanium Anode and Platinum Plated Titanium expanded Metal)

FAQs of Micro Coated Titanium Anode and Platinum Plated Titanium expanded Metal

Inquiry us