Overview of Iron nickel molybdenum magnetic ring MP-108060-2

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Iron nickel molybdenum magnetic ring MP-108060-2

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

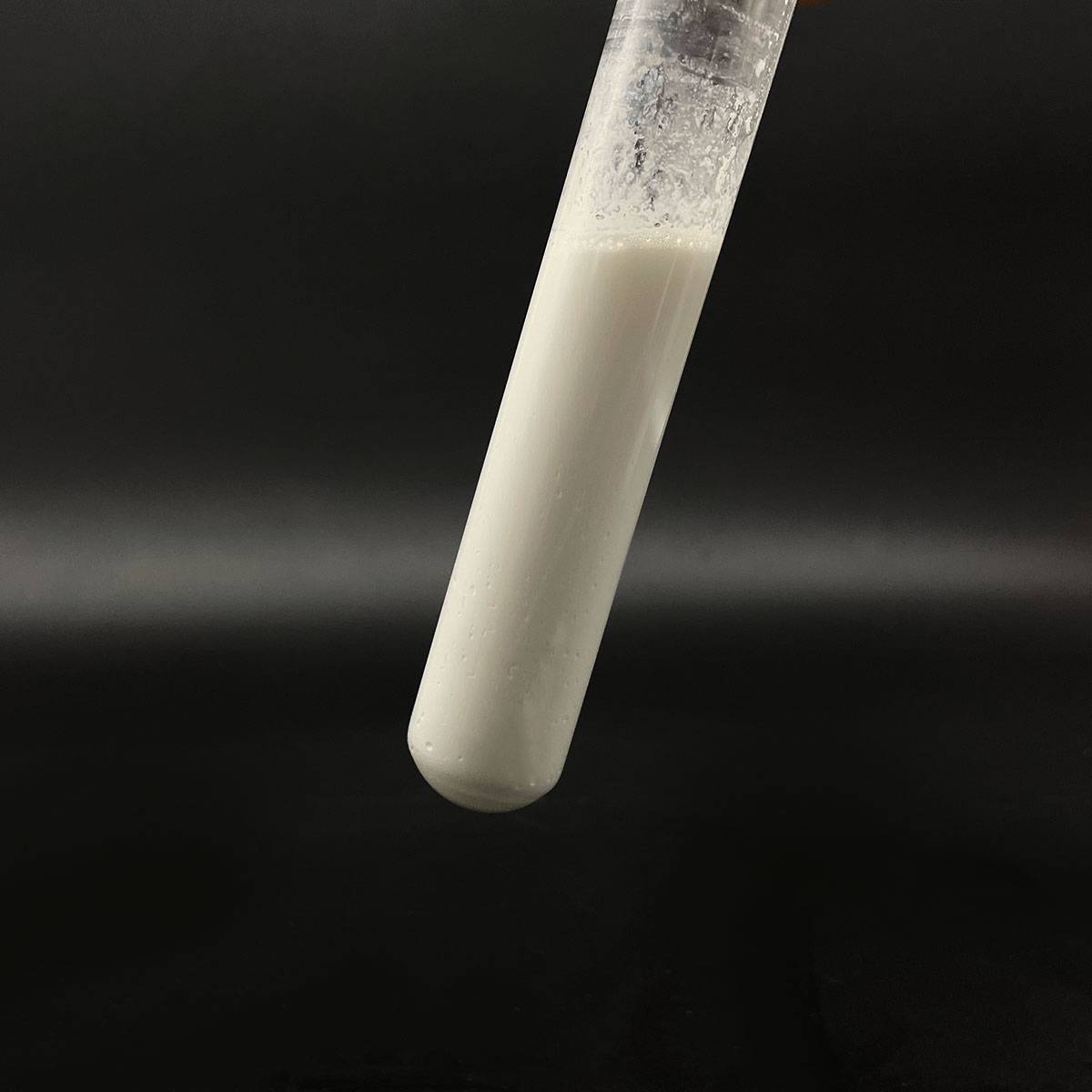

(Iron nickel molybdenum magnetic ring MP-108060-2)

Parameters of Iron nickel molybdenum magnetic ring MP-108060-2

The MP-108060-2 is a specialized magnetic component, specifically an iron-nickel-molybdenum (INM) ring, designed for various applications requiring strong magnetic properties and durability. This particular model, without a specific format provided, likely falls under the category of rare-earth magnet technology, combining the advantageous characteristics of iron, nickel, and molybdenum.

Iron-nickel alloys are known for their high magnetic permeability, which allows them to easily align with external magnetic fields. Nickel, on the other hand, enhances the stability of the magnetic properties over time, making it a valuable addition to the composition. Molybdenum further improves the alloy’s mechanical strength and resistance to corrosion, ensuring the ring’s longevity in harsh environments.

The MP-108060-2’s dimensions, although not explicitly stated, suggest that it might be a precision-engineered component with a diameter of 108 millimeters and a height or thickness of 60 millimeters. These dimensions could be critical for optimal performance in magnetic systems, such as motors, generators, or electromagnetic devices where precise magnetic field distribution is essential.

One of the key parameters of this ring is its coercivity, which measures its ability to resist demagnetization. A higher coercivity indicates stronger magnetic retention, making it suitable for applications where sustained magnetic field is required, like in permanent magnets or electromagnets with frequent cycling.

Another important aspect is the remanence, or residual magnetism, which refers to the magnetization remaining after the external magnetic field is removed. The MP-108060-2’s remanence would be another crucial parameter, as it determines the ring’s ability to maintain its magnetic field even when power is momentarily interrupted.

The MP-108060-2 may also possess a grade classification, which denotes the quality and performance level of the material. This could include grades based on the level of purity, magnetic saturation, or energy product, all of which contribute to the overall efficiency and reliability of the magnetic ring.

In summary, the MP-108060-2 is a high-quality iron-nickel-molybdenum magnetic ring, designed for demanding applications that demand strong, stable, and long-lasting magnetic performance. Its precise dimensions, high coercivity, and remanence make it an ideal choice for various engineering solutions, such as motors, generators, or magnetic sensors. Further information about the specific technical specifications and performance would be necessary to provide a more detailed analysis.

(Iron nickel molybdenum magnetic ring MP-108060-2)

FAQs of Iron nickel molybdenum magnetic ring MP-108060-2

Inquiry us