Overview of High temperature box furnace heating element silicon carbide tungsten and molybdenum metal powder sintering furnace

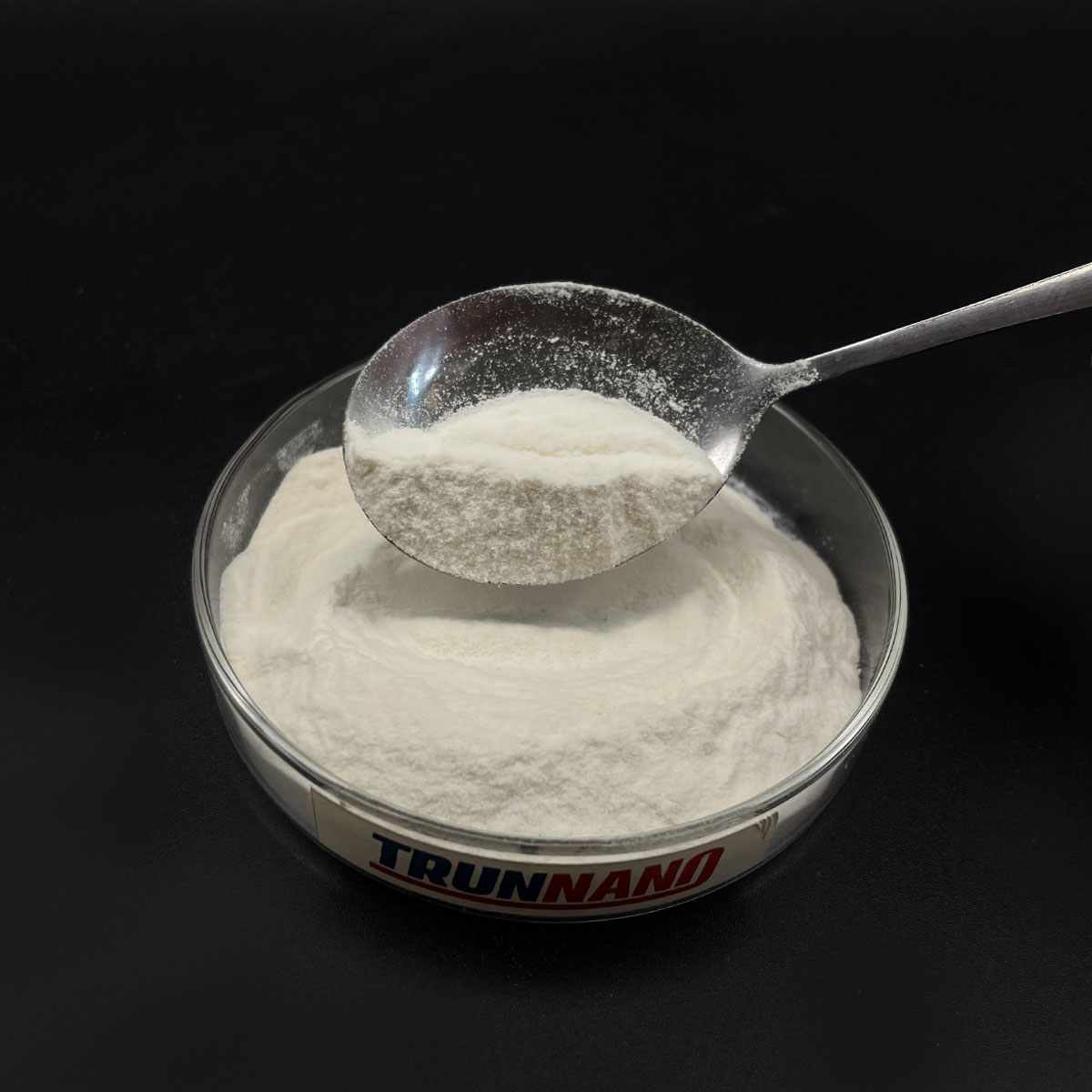

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High temperature box furnace heating element silicon carbide tungsten and molybdenum metal powder sintering furnace

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High temperature box furnace heating element silicon carbide tungsten and molybdenum metal powder sintering furnace)

Parameters of High temperature box furnace heating element silicon carbide tungsten and molybdenum metal powder sintering furnace

A high-temperature box furnace designed for sintering applications, utilizing a combination of heating elements made from silicon carbide, tungsten, and molybdenum metal powders, is a specialized piece of equipment that plays a crucial role in the manufacturing process of advanced materials. This furnace offers a controlled environment for the consolidation and densification of these powders into their final form.

The primary component of this furnace is the heating element, which is composed of a composite material consisting of silicon carbide (SiC) as the base. Silicon carbide is known for its exceptional thermal stability, high melting point (over 2600°C), and excellent resistance to wear and chemical, making it an ideal choice for high-temperature applications. The tungsten and molybdenum powders are incorporated to enhance the overall performance, providing enhanced conductivity and heat transfer capabilities.

The heating element design typically employs a wire or rod configuration, with tungsten and molybdenum forming a coating or alloy on the SiC core. This combination ensures efficient heat distribution and minimizes energy losses, resulting in rapid and uniform temperature control within the furnace chamber. The precise proportions of these metals can be tailored to meet specific requirements, such as higher melting points, improved mechanical strength, or enhanced corrosion resistance.

The furnace itself is a robust, insulated structure, often constructed from high-temperature ceramics like alumina or silica, providing excellent insulation and minimizing heat loss. It features a box-shaped design, allowing for ample space for the placement of the heating element and sample materials. The chamber is typically lined with a refractory material to withstand the elevated temperatures and protect against chemical reactions with the furnace walls.

Temperature control is a critical aspect of this furnace, with programmable controllers enabling users to set and maintain temperatures up to 1800°C or more, depending on the specific model. The furnace may feature multiple zones for independent temperature control, enabling the sintering of multi-component materials with varying thermal expansion coefficients.

Air or inert gas circulation systems are employed to ensure uniform heating and minimize oxidation of the samples or heating elements. These systems can be adjusted to maintain the required atmosphere, whether it’s vacuum, argon, nitrogen, or another protective gas, depending on the material being processed.

Safety features, such as overtemperature protection and interlocks, are standard in high-temperature box furnaces to prevent accidents and safeguard the operator. Additionally, the furnace is equipped with a robust cooling system that gradually brings the temperature down after the sintering process, ensuring proper quenching and preventing thermal shock.

In summary, a high-temperature box furnace incorporating silicon carbide, tungsten, and molybdenum metal powders is a sophisticated piece of equipment that enables the sintering of advanced materials under controlled conditions. Its unique heating element design, coupled with precise temperature control and customizable atmosphere options, makes it a versatile tool for researchers and manufacturers working in various industries, including electronics, aerospace, and energy production.

(High temperature box furnace heating element silicon carbide tungsten and molybdenum metal powder sintering furnace)

FAQs of High temperature box furnace heating element silicon carbide tungsten and molybdenum metal powder sintering furnace

Inquiry us