Overview of Customized High-Entropy Alloys Nickel Cobalt Chromium Aluminum Yttrium Tantalum NiCoCrAlYTa Alloy Target for Coating

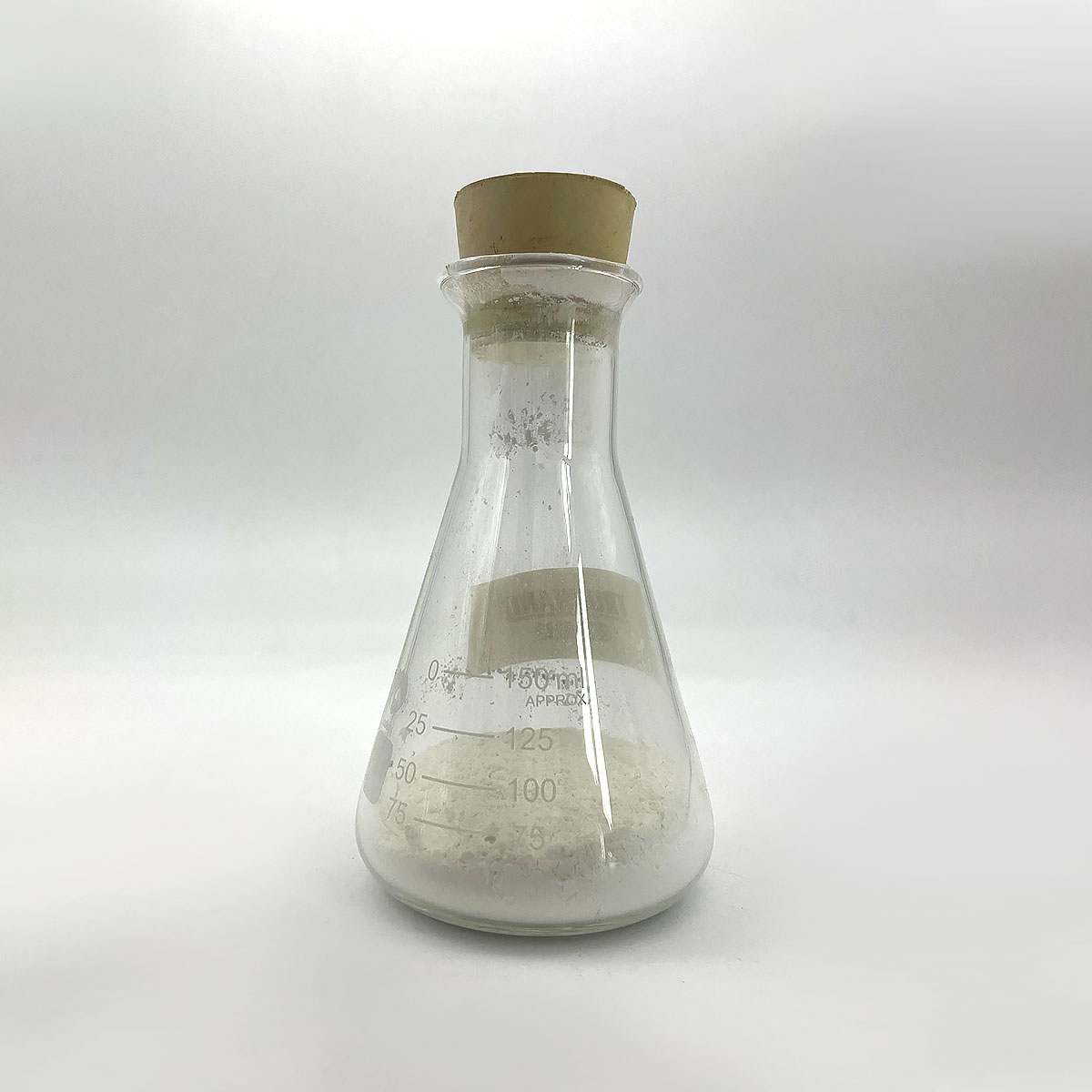

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Customized High-Entropy Alloys Nickel Cobalt Chromium Aluminum Yttrium Tantalum NiCoCrAlYTa Alloy Target for Coating

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Customized High-Entropy Alloys Nickel Cobalt Chromium Aluminum Yttrium Tantalum NiCoCrAlYTa Alloy Target for Coating)

Parameters of Customized High-Entropy Alloys Nickel Cobalt Chromium Aluminum Yttrium Tantalum NiCoCrAlYTa Alloy Target for Coating

Title: A Comprehensive Overview of Customized High-Entropy Nickel Cobalt Chromium Aluminum Yttrium Tantalum (NiCoCrAlYTa) Alloy Target for Coating Applications

High-Entropy Alloys (HEAs) have emerged as a groundbreaking materials science concept, revolutionizing the field of coatings due to their unique combination of elements and exceptional properties. One such alloy, NiCoCrAlYTa, is a prime example of this innovation, showcasing remarkable strength, corrosion resistance, and thermal stability. This targeted alloy specifically designed for coating applications offers a tailored solution for industries seeking enhanced performance in demanding environments.

The NiCoCrAlYTa alloy is composed of five principal elements: Nickel (Ni), Cobalt (Co), Chromium (Cr), Aluminum (Al), Yttrium (Y), and Tantalum (Ta). The high-entropy principle lies in the equal or near-equal atomic concentrations of these elements, typically between 5-35%, which results in a disordered crystal structure, known as a solid solution. This disordered structure imparts exceptional mechanical properties and chemical resistance compared to conventional alloys.

One of the key features of this alloy is its exceptional strength at elevated temperatures. The combination of Ni, Co, and Cr forms a strong base, while the addition of Al, Y, and Ta provides additional strengthening mechanisms through precipitation hardening and grain refinement. This makes NiCoCrAlYTa an ideal choice for applications where resistance to thermal fatigue and creep deformation is critical.

The corrosion resistance of NiCoCrAlYTa is another standout characteristic. The presence of chromium, yttrium, and tantalum, along with the disordered structure, hinders the formation of detrimental passive films, making it resistant to various corrosive environments, including acidic and chloride media. This is particularly beneficial for industries like aerospace, marine, and chemical processing, where exposure to corrosive conditions is common.

In terms of coating parameters, the NiCoCrAlYTa alloy target can be customized to optimize performance based on specific application requirements. Factors such as particle size, morphology, and surface finish can be controlled during the manufacturing process, affecting the coating’s adherence, wear resistance, and thermal conductivity. By adjusting the alloy composition and processing techniques, it is possible to tailor the coating properties to match the substrate material and desired service conditions.

The microstructure of the NiCoCrAlYTa alloy can also be manipulated to achieve desired properties. For instance, by controlling the cooling rate during solidification, fine-grained or dual-phase structures can be produced, leading to improved mechanical properties and enhanced resistance to deformation.

Moreover, the NiCoCrAlYTa alloy is compatible with various coating methods, including physical vapor deposition (PVD), chemical vapor deposition (CVD), and electrodeposition. These processes allow for the formation of thin, adherent layers with excellent mechanical and tribological characteristics, further enhancing the overall performance of the coated components.

In conclusion, the NiCoCrAlYTa high-entropy alloy target presents a versatile and customizable solution for coating applications. Its unique combination of elements, coupled with the ability to tailor the microstructure and processing parameters, makes it a promising material for industries seeking improved performance, durability, and corrosion resistance in challenging environments. As research and development in HEAs continue, NiCoCrAlYTa is poised to play a significant role in pushing the boundaries of coating technology.

(Customized High-Entropy Alloys Nickel Cobalt Chromium Aluminum Yttrium Tantalum NiCoCrAlYTa Alloy Target for Coating)

FAQs of Customized High-Entropy Alloys Nickel Cobalt Chromium Aluminum Yttrium Tantalum NiCoCrAlYTa Alloy Target for Coating

Inquiry us