Overview of Factory Directly Supply Nano Tantalum Powder 99.9% Min

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory Directly Supply Nano Tantalum Powder 99.9% Min

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

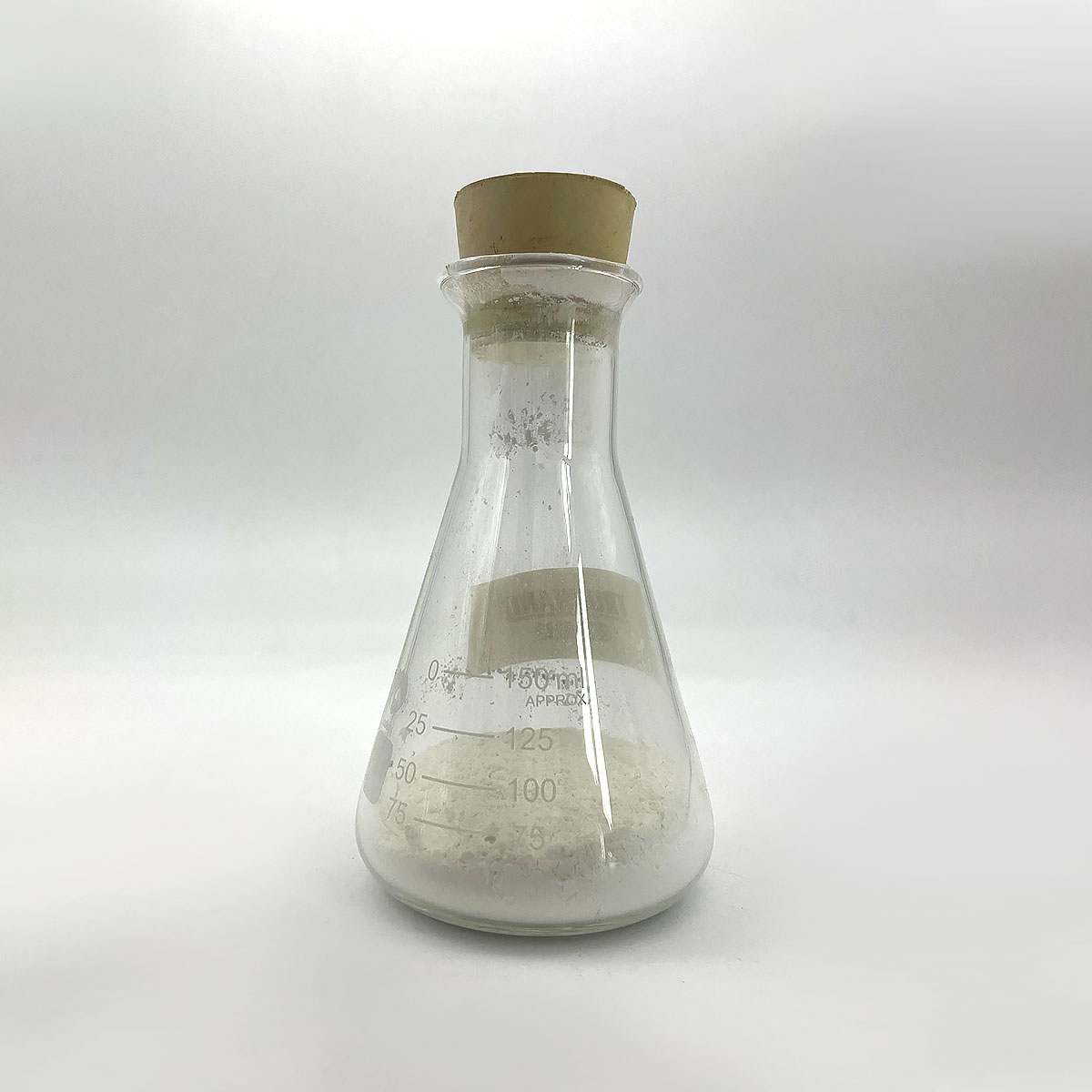

(Factory Directly Supply Nano Tantalum Powder 99.9% Min)

Parameters of Factory Directly Supply Nano Tantalum Powder 99.9% Min

Title: High-Quality Nano Tantalum Powder – Factory Direct Supply, 99.9% Purity

Introduction:

In the world of advanced materials and cutting-edge technology, our factory is proud to offer you a premium product – Nano Tantalum Powder with an exceptional purity level of 99.9%. This pure form of tantalum offers unparalleled performance and versatility in various industries, including electronics, aerospace, and energy storage systems. Our commitment to direct supply ensures that you receive the highest quality material, eliminating the need for intermediaries and providing you with a competitive advantage.

Composition and Purity:

Our Nano Tantalum Powder is characterized by its ultra-fine particle size, typically ranging from 50 to 200 nanometers. The 99.9% purity guarantees that each batch is meticulously processed to minimize impurities, ensuring maximum efficiency and reliability in your applications. This high purity allows for superior conductivity, corrosion resistance, and thermal stability, making it an ideal choice for demanding applications.

Manufacturing Process:

Our manufacturing process begins with the sourcing of top-grade tantalum ore, which we subject to rigorous purification procedures. We employ advanced techniques such as electrolysis and chemical refining to refine the tantalum to its purest form. Following this, we utilize state-of-the-art nano-technology to reduce the particles to the nanoscale, creating a surface area that enhances its properties significantly.

Direct Supply Chain:

By operating a direct supply chain, we eliminate the need for multiple layers of distribution, resulting in significant cost savings for our customers. This streamlined process ensures prompt delivery, eliminating potential delays and maintaining the integrity of the product throughout the supply chain. You can trust that the Nano Tantalum Powder you receive directly from us is fresh, consistent, and ready for immediate use.

Applications:

The benefits of our Nano Tantalum Powder extend across numerous industries. In electronics, it is utilized in capacitors and microelectronic devices due to its excellent electrical conductivity and stability. Aerospace applications benefit from its lightweight yet strong properties, making it ideal for components in high-temperature environments. Additionally, it finds application in energy storage systems, where its high capacitance and long cycle life contribute to better performance.

Customer Support:

At our factory, we prioritize customer satisfaction. Our knowledgeable team is available to provide technical assistance, help with product selection, and answer any queries you may have about our Nano Tantalum Powder. We understand the importance of using the right material for your specific needs, and we are dedicated to ensuring your success.

Conclusion:

In conclusion, our factory-direct supply of 99.9% pure Nano Tantalum Powder represents a reliable and efficient solution for your advanced material requirements. With its exceptional purity, enhanced properties, and direct supply chain, our product is poised to revolutionize your processes and contribute to the success of your projects. Contact us today to experience the benefits of our Nano Tantalum Powder firsthand and unlock new possibilities for your business.

(Factory Directly Supply Nano Tantalum Powder 99.9% Min)

FAQs of Factory Directly Supply Nano Tantalum Powder 99.9% Min

Inquiry us