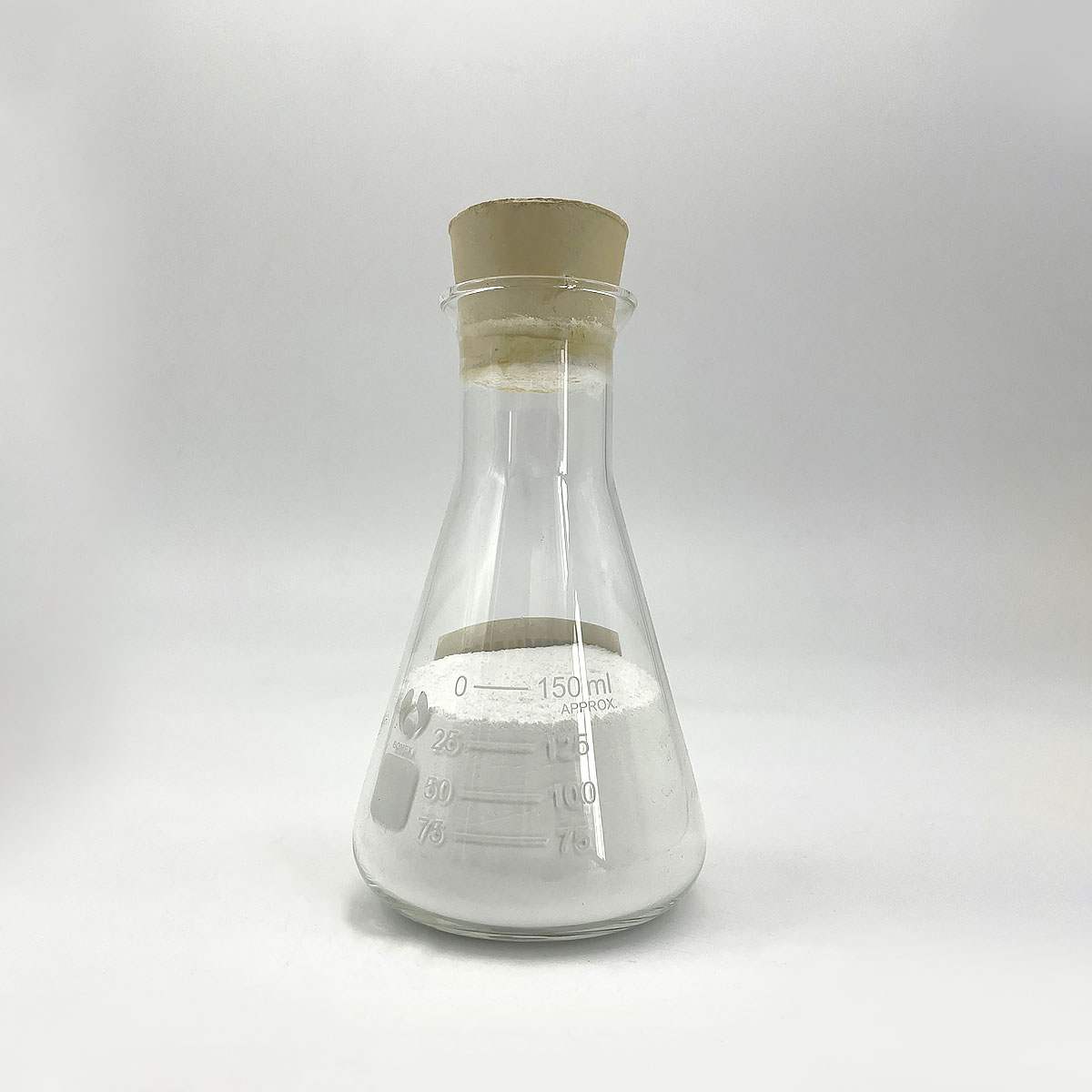

Overview of 86WC10Co4Cr thermal spray powder tungsten carbide cobalt chrome powder for rollers

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of 86WC10Co4Cr thermal spray powder tungsten carbide cobalt chrome powder for rollers

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(86WC10Co4Cr thermal spray powder tungsten carbide cobalt chrome powder for rollers)

Parameters of 86WC10Co4Cr thermal spray powder tungsten carbide cobalt chrome powder for rollers

The 86WC10Co4Cr thermal spray powder, specifically designed for tungsten carbide cobalt chrome, is a high-performance material widely utilized in various industrial applications, particularly for roller manufacturing. This particular composition boasts exceptional wear resistance, thermal stability, and excellent mechanical properties, making it an ideal choice for demanding environments where longevity and efficiency are paramount.

Tungsten carbide (WC), with its high hardness and fracture toughness, forms the backbone of the compound. It provides exceptional hardness and wear resistance, ensuring that rollers maintain their shape and integrity under heavy loads and high-temperature conditions. The 10% tungsten content ensures a strong and durable structure.

Cobalt (Co) is added to enhance the alloy’s machinability and improve its red hardness, which is crucial for roller applications that may involve frequent re-machining or reshaping. It also contributes to better thermal stability, allowing the material to maintain its performance even when subjected to thermal cycling.

The 4% chromium (Cr) content offers additional wear resistance and corrosion protection. Chromium increases the material’s resistance to oxidation and improves its surface finish, contributing to a smoother operation and longer service life for the rollers.

The thermal spray process used to produce this powder involves atomizing the tungsten carbide cobalt chrome particles at high temperatures, creating a fine mist that adheres to a substrate during the deposition process. This method ensures a uniform coating with minimal porosity and intermetallic phases, resulting in a strong bond between the sprayed layer and the base material.

Some key parameters of the 86WC10Co4Cr powder include:

1. Particle size distribution: The powder is carefully controlled to ensure a consistent particle size, which affects the coating’s density, adhesion, and overall performance.

2. Melting point: The high melting point of this alloy allows for successful thermal spraying without significant degradation of the powder.

3. Coefficient of thermal expansion (CTE): A low CTE is essential to minimize thermal stresses and prevent cracking during temperature fluctuations.

4. Hardness: The as-sprayed WC10Co4Cr layer typically exhibits a Rockwell hardness of around 90 HRA, providing exceptional properties.

5. Wear rate: The combination of tungsten carbide and cobalt-chrome makes the material resistant to abrasive wear, extending the life of the rollers.

6. Corrosion resistance: The presence of chromium enhances the powder’s resistance to chemical attack, ensuring minimal degradation in corrosive environments.

In summary, the 86WC10Co4Cr thermal spray powder is a cutting-edge material for roller applications due to its exceptional wear resistance, thermal stability, and superior mechanical properties. Its unique composition, combined with the thermal spray process, results in a robust and long-lasting solution for industries such as mining, steel production, and heavy machinery. With its tailored properties, this powder enables rollers to perform optimally under harsh conditions, reducing downtime and maintenance costs.

(86WC10Co4Cr thermal spray powder tungsten carbide cobalt chrome powder for rollers)

FAQs of 86WC10Co4Cr thermal spray powder tungsten carbide cobalt chrome powder for rollers

Inquiry us