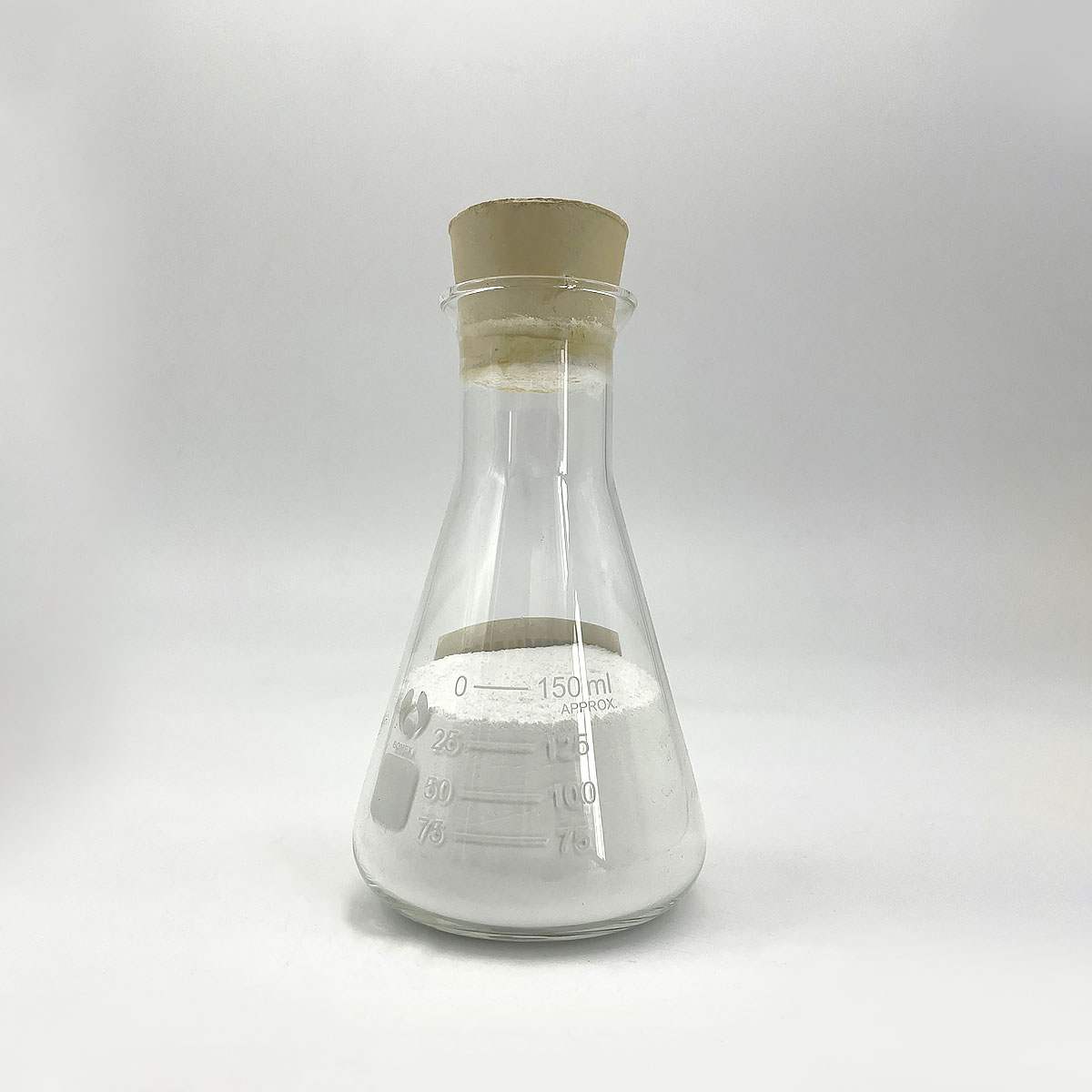

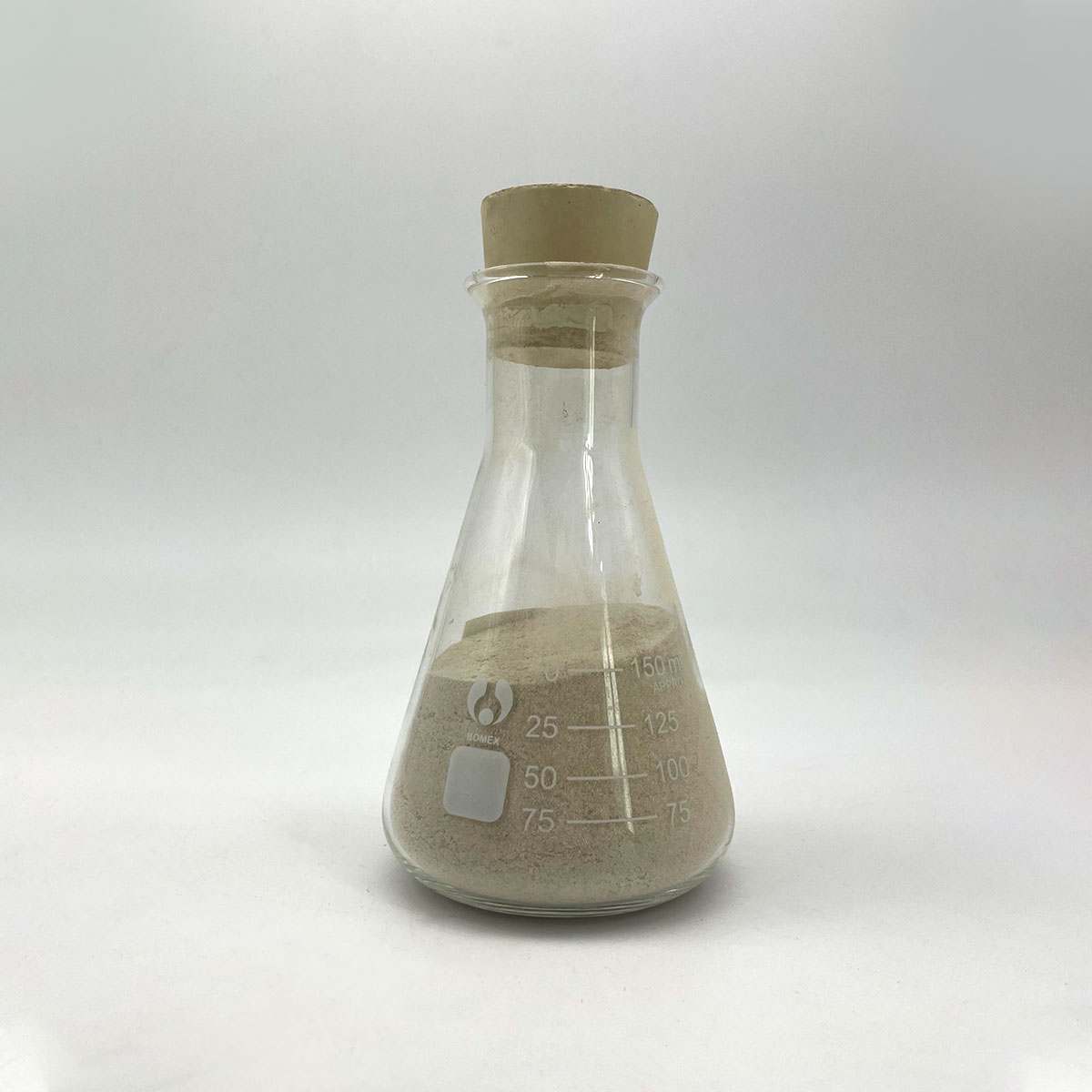

Overview of Factory Produce Agglomeration sintering WC 10Ni -45 +20um tungsten carbide powder WOKA 3307

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory Produce Agglomeration sintering WC 10Ni -45 +20um tungsten carbide powder WOKA 3307

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Factory Produce Agglomeration sintering WC 10Ni -45 +20um tungsten carbide powder WOKA 3307)

Parameters of Factory Produce Agglomeration sintering WC 10Ni -45 +20um tungsten carbide powder WOKA 3307

Title: Sintering Process of WC 10Ni-45 Tungsten Carbide Powder (WOKA 3307) for Advanced Applications

Introduction:

The manufacturing of high-performance tungsten carbide materials, such as WC 10Ni-45 +20um tungsten carbide powder (WOKA 3307), involves a sophisticated process known as agglomeration and sintering. This advanced material finds its application in various industries, including cutting tools, wear-resistant components, and aerospace engineering due to its exceptional hardness, wear resistance, and thermal stability.

Agglomeration:

Agglomeration is the initial stage where fine tungsten carbide particles are compacted and bonded together to form larger aggregates or pre-sintered bodies. The WOKA 3307 powder, characterized by a 10% nickel content and a particle size of 20 microns, undergoes this step using specialized techniques. The process typically involves the addition of binders, lubricants, and sometimes sintering aids to facilitate easy handling, reduce friction during mixing, and ensure proper bonding between particles without compromising the final properties.

Mechanism:

During agglomeration, the powders are mixed under controlled conditions, often in a tumbling drum or vibratory mixer, to achieve a uniform distribution of the components. The binder melts and acts as a glue, holding the particles together while forming cohesive aggregates. The lubricants prevent excessive adhesion, allowing for easy removal of the formed agglomerates. Once the desired agglomerate size is achieved, the excess binder is removed through calcination or sintering, leaving behind strong, well-defined particle bonds.

Sintering:

The next critical step is sintering, which consolidates the agglomerates into a dense, fully bonded structure. Sintering WOKA 3307 takes place at temperatures typically ranging from 1600°C to 2200°C, depending on the specific composition and required mechanical properties. During this process, the tungsten carbide particles undergo diffusion, filling the gaps between them, and the nickel serves as a solid solution strengthening agent, enhancing the material’s hardness and wear resistance.

Parameters:

To optimize the sintering process for WOKA 3307, several parameters need to be carefully controlled. These include:

1. Temperature: Maintaining an accurate temperature profile ensures uniform densification and minimizes grain growth, which can affect mechanical properties.

2. Time: The duration of sintering affects the degree of densification and microstructure development. Longer times allow for better consolidation but may lead to grain coarsening if not managed correctly.

3. Atmosphere: An inert atmosphere, such as argon or helium, is commonly used to minimize oxidation and ensure pure tungsten carbide is produced.

4. Pressure: Applying slight pressure during sintering can enhance densification and improve mechanical strength.

5. Heating rate: A controlled heating rate helps to minimize internal stresses and promote uniform sintering.

In conclusion, the agglomeration and sintering of WC 10Ni-45 +20um tungsten carbide powder (WOKA 3307) is a critical process that results in a high-performance material suitable for demanding applications. By meticulously controlling the parameters mentioned above, manufacturers can produce tungsten carbide with the desired properties, making it a vital component in modern technology and engineering.

(Factory Produce Agglomeration sintering WC 10Ni -45 +20um tungsten carbide powder WOKA 3307)

FAQs of Factory Produce Agglomeration sintering WC 10Ni -45 +20um tungsten carbide powder WOKA 3307

Inquiry us