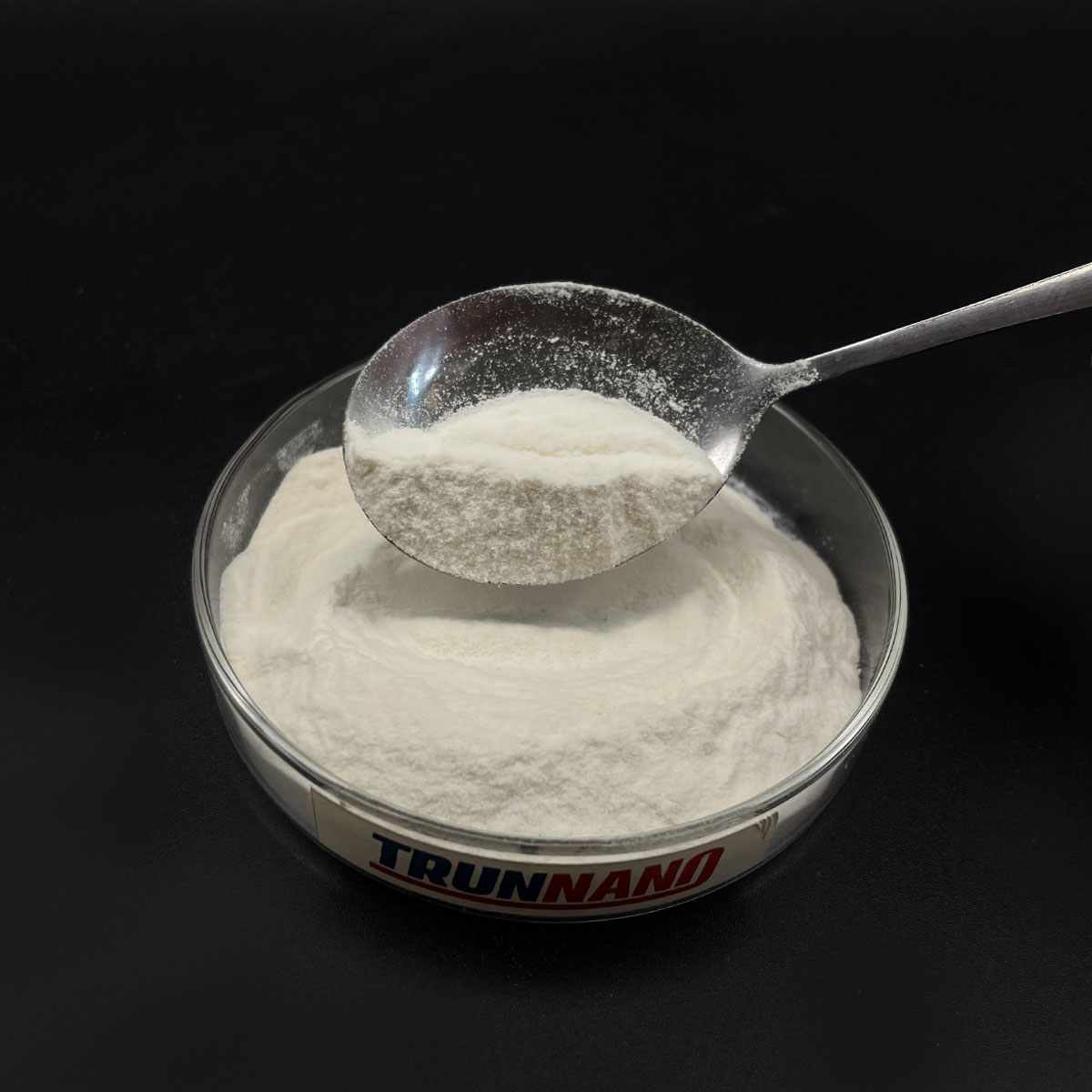

Overview of Ultrapure 90% Titanium Aluminum Carbide Ti3AlC2 Max Powder 400Mesh with Factory

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Ultrapure 90% Titanium Aluminum Carbide Ti3AlC2 Max Powder 400Mesh with Factory

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Ultrapure 90% Titanium Aluminum Carbide Ti3AlC2 Max Powder 400Mesh with Factory )

Parameters of Ultrapure 90% Titanium Aluminum Carbide Ti3AlC2 Max Powder 400Mesh with Factory

Title: Ultra-Pure Titanium Aluminum Carbide (Ti3AlC2) MAX Powder: A High-Quality 400 Mesh Product with Exceptional Specifications

Introduction:

The ultrapure 90% Titanium Aluminum Carbide (Ti3AlC2) MAX powder, specifically designed for advanced industrial applications, boasts exceptional performance due to its high purity and fine particle size of 400 mesh. This material, manufactured by reputable factories with stringent quality control measures, is an indispensable component in various industries such as aerospace, automotive, and electronics.

Composition and Purity:

Ti3AlC2, a ternary carbide compound, consists of 90% titanium (Ti), 9% aluminum (Al), and 1% carbon (C). The high purity of this powder ensures minimal impurities, which is crucial for achieving optimal performance and reliability in demanding environments. The absence of contaminants enhances the material’s strength, wear resistance, and thermal stability.

Particle Size and Distribution:

The 400 mesh particle size of this powder guarantees a uniform distribution, facilitating easy processing and homogeneous integration into various substrates. The small particle size also increases the surface area, promoting rapid bonding during sintering or melting, leading to enhanced mechanical properties and improved functional performance.

Properties and Benefits:

Ultrapure Ti3AlC2 MAX powder exhibits remarkable mechanical properties, including high hardness, excellent thermal conductivity, and low density. These characteristics make it ideal for lightweight, high-performance components, such as aerospace engine parts or electronic heat sinks. Its superior tribological properties ensure long-lasting durability and minimal friction in sliding applications.

Manufacturing Process:

Factories that produce this ultra-pure Ti3AlC2 MAX powder adhere to strict quality control protocols, ensuring the consistent production of particles with the desired crystal structure. The process typically involves chemical vapor deposition (CVD) or mechanical alloying, followed by purification and milling to achieve the final 400 mesh particle size.

Applications:

This advanced powder finds extensive use across multiple industries. In aerospace, it is used in the fabrication of lightweight structural components, while in the automotive sector, it supports the development of high-performance braking systems. Electronics manufacturers employ Ti3AlC2 MAX for heat spreaders and heat dissipation solutions. Additionally, it has potential applications in the manufacturing of cutting tools, wear-resistant coatings, and even in the emerging field of additive manufacturing.

Conclusion:

In summary, the ultrapure 90% Titanium Aluminum Carbide Ti3AlC2 MAX powder with a 400 mesh particle size represents a premium material choice for engineers and manufacturers seeking exceptional performance, durability, and efficiency. The factory-produced powder with its standardized specifications guarantees reliable results and contributes to the advancement of modern technology across diverse industries.

(Ultrapure 90% Titanium Aluminum Carbide Ti3AlC2 Max Powder 400Mesh with Factory )

FAQs of Ultrapure 90% Titanium Aluminum Carbide Ti3AlC2 Max Powder 400Mesh with Factory

Inquiry us