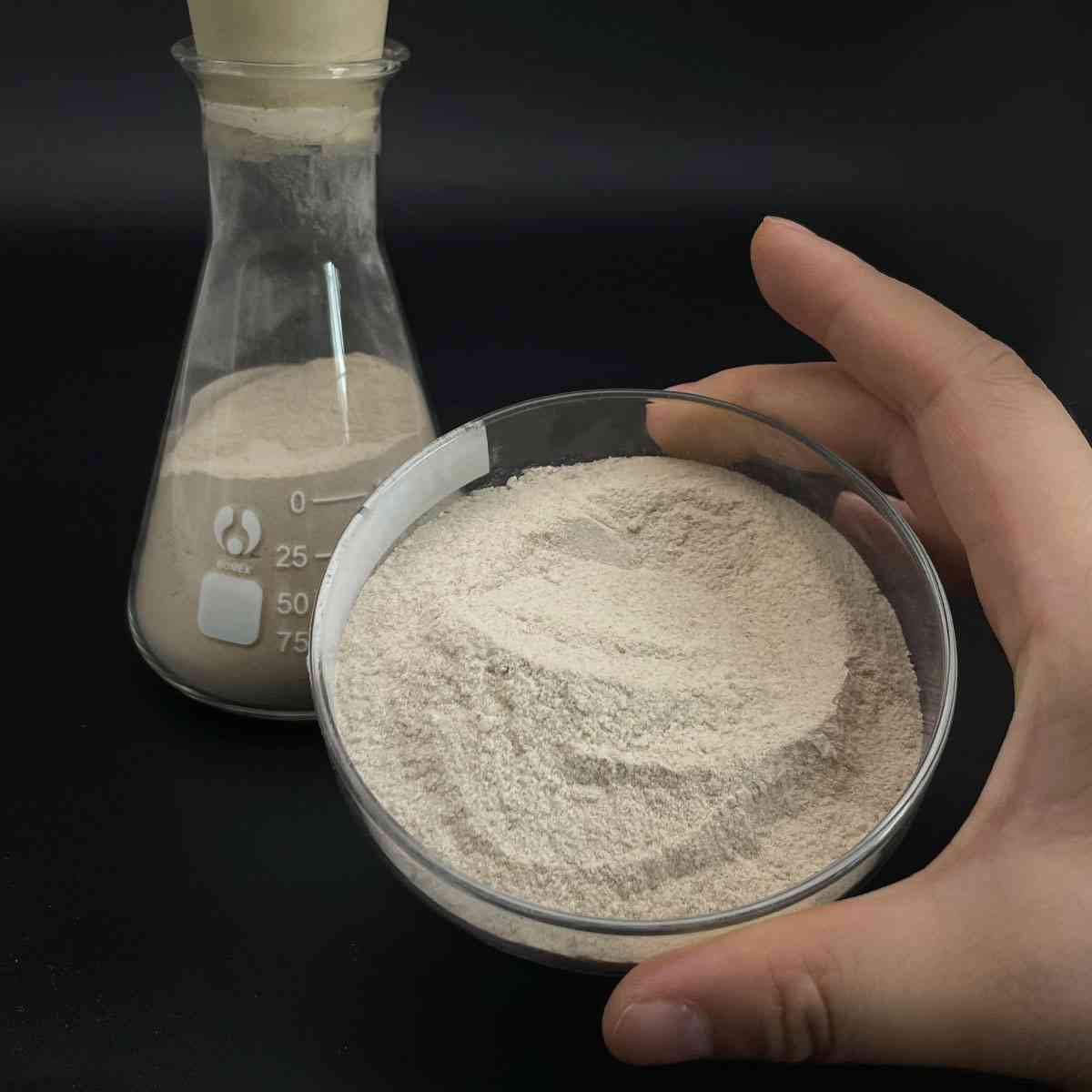

Overview of Ultra Pure (99.95%) Metallurgical Spherical Metal Powder Tantalum Powder From China Used in Surface Spraying

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Ultra Pure (99.95%) Metallurgical Spherical Metal Powder Tantalum Powder From China Used in Surface Spraying

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Ultra Pure (99.95%) Metallurgical Spherical Metal Powder Tantalum Powder From China Used in Surface Spraying)

Parameters of Ultra Pure (99.95%) Metallurgical Spherical Metal Powder Tantalum Powder From China Used in Surface Spraying

Title: Ultra-Pure (99.95%) Metallurgical Spherical Tantalum Powder: A High-Quality Solution for Surface Spraying Applications in China

Introduction:

In the realm of advanced materials, metallurgical spherical tantalum powder stands out as a premium choice for various industrial applications, particularly in surface spraying. Originating from China, this ultra-pure product with a remarkable 99.95% purity level ensures unparalleled performance and reliability. This detailed overview highlights the key features, benefits, and parameters involved in utilizing this tantalum powder for optimal results.

Properties of Ultra-Pure Tantalum Powder:

The core characteristic of this tantalum powder is its exceptional purity, which guarantees minimal impurities and enhances its inherent properties. The spherical shape, achieved through advanced metallurgical processes, ensures consistent particle size distribution and improved flowability, making it ideal for surface treatments like electroplating, coating, and thermal spray applications.

Surface Spraying Parameters:

When used in surface spraying, the metallurgical spherical tantalum powder exhibits specific parameters that contribute to its effectiveness. These include:

1. Particle Size: The powder’s uniform spherical structure ranges from submicron to micron sizes, allowing for efficient bonding with substrates and achieving a smooth, durable finish.

2. Pore Structure: The tightly packed particles result in a low porosity, which minimizes voids and improves the mechanical strength of the sprayed layer.

3. Adhesion: The high purity of the tantalum powder ensures strong adhesion to various surfaces, providing excellent corrosion resistance and wear protection.

4. Thermal Conductivity: Tantalum’s inherent thermal conductivity helps dissipate heat effectively, preventing overheating during high-temperature applications.

5. Chemical Stability: At 99.95% purity, the powder maintains its integrity under harsh chemical environments, making it suitable for demanding industrial settings.

6. Deposition Efficiency: The spherical shape promotes even deposition, minimizing wastage and ensuring optimal utilization of the material.

Applications:

This ultra-pure tantalum powder finds extensive use in industries such as aerospace, automotive, electronics, and medical devices. Key applications include:

– Aerospace: Tantalum’s high melting point and lightweight properties make it ideal for engine components and heat shields.

– Automotive: It is used in exhaust systems, bearings, and high-performance parts requiring durability and corrosion resistance.

– Electronics: Tantalum capacitors and connectors offer superior stability and reliability in electronic devices.

– Medical Devices: Tantalum is employed in orthopedic implants and dental prosthetics due to its biocompatibility and long-term performance.

Conclusion:

In summary, the 99.95% pure, metallurgical spherical tantalum powder from China is an exceptional material for surface spraying applications. Its superior properties, precise sizing, and excellent performance in various environments make it a preferred choice for industries seeking enhanced durability, corrosion resistance, and efficiency. By understanding these key parameters, engineers and manufacturers can harness the full potential of this high-quality tantalum powder for their projects.

(Ultra Pure (99.95%) Metallurgical Spherical Metal Powder Tantalum Powder From China Used in Surface Spraying)

FAQs of Ultra Pure (99.95%) Metallurgical Spherical Metal Powder Tantalum Powder From China Used in Surface Spraying

Inquiry us