Overview of Tungsten Carbide Powder WC12Co/WC10Co4Cr Powder for HVOF

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Tungsten Carbide Powder WC12Co/WC10Co4Cr Powder for HVOF

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

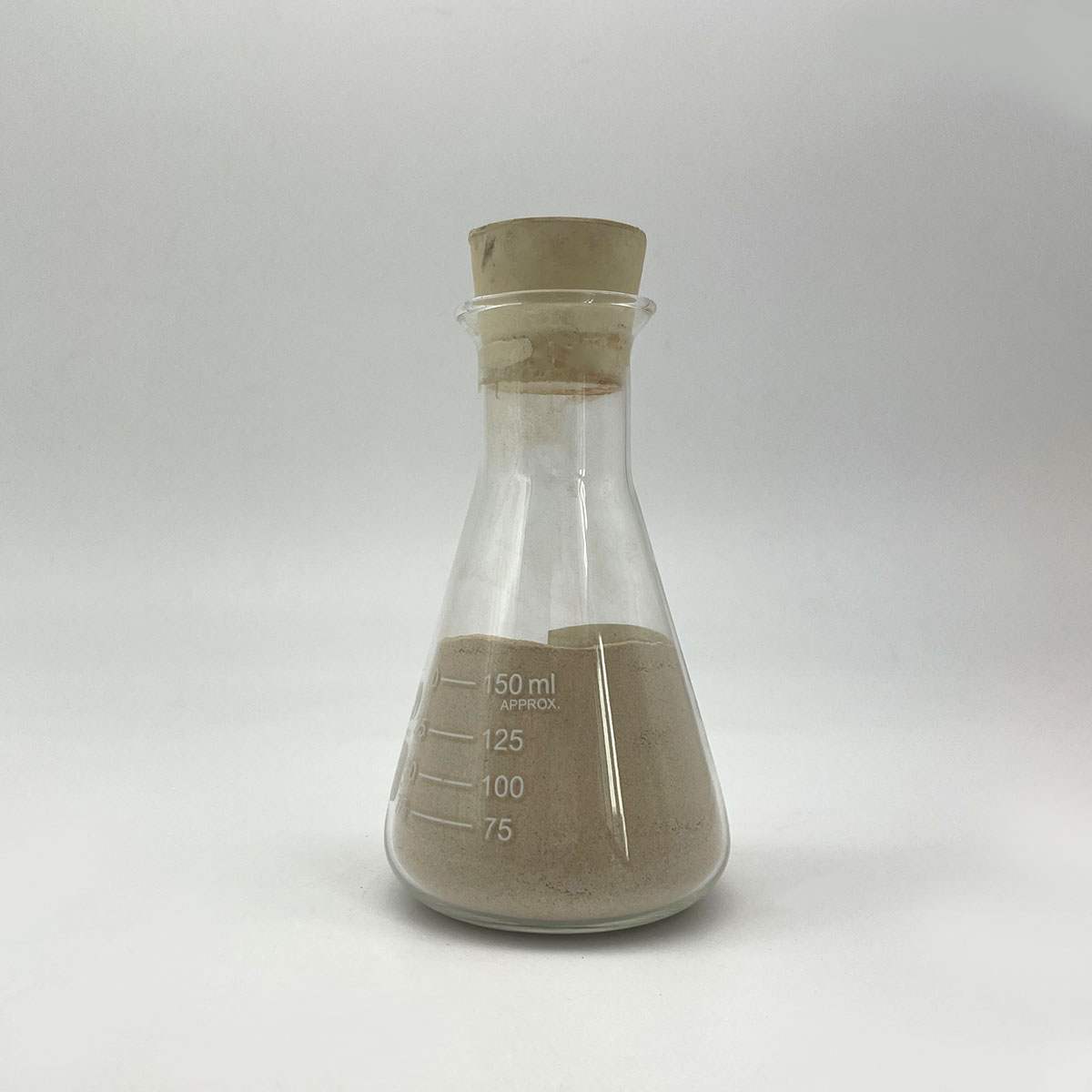

(Tungsten Carbide Powder WC12Co/WC10Co4Cr Powder for HVOF)

Parameters of Tungsten Carbide Powder WC12Co/WC10Co4Cr Powder for HVOF

Tungsten carbide, a high-performance material known for its exceptional hardness, wear resistance, and thermal stability, is widely used in various industries, including cutting tools, wear-resistant coatings, and components. WC powders, specifically WC12Co and WC10Co4Cr, are of significant interest due to their tailored properties that make them ideal for high-velocity oxygen fuel (HVOF) spray deposition processes.

WC12Co, also referred to as tungsten carbide with 12% cobalt, contains a higher percentage of cobalt compared to WC10Co4Cr. Cobalt acts as a binder in the powder, enhancing the sinterability and promoting better mechanical properties when heated during the HVOF process. This composition results in a material with excellent toughness, which is crucial for applications where impact resistance is essential, such as in mining, construction, or aerospace.

WC10Co4Cr, on the other hand, features a lower cobalt content (10%) and includes 4% chromium. The addition of chromium improves the wear resistance and oxidation resistance, making it suitable for applications in corrosive environments or where exposure to abrasive materials is likely. The HVOF parameters for WC10Co4Cr tend to focus on achieving a fine grain structure and high bond strength, which translates to longer tool life and better surface finish.

In HVOF spraying, the powders are atomized by a high-pressure oxygen jet and mixed with fuel, typically a hydrocarbon gas, before being accelerated towards a substrate at supersonic speeds. The process involves heating the powder mixture to temperatures above its melting point, creating a plasma stream that deposits the tungsten carbide particles on the substrate with high energy and precision. The HVOF parameters, such as gas flow rate, powder feed rate, and temperature, are carefully controlled to optimize the coating’s microstructure, porosity, and adherence.

For WC12Co, the HVOF parameters may involve a slightly higher gas flow rate to accommodate the increased cobalt content, which can lead to a denser and more homogeneous coating. The temperature may be set to ensure complete melting and proper bonding between particles. In contrast, WC10Co4Cr might require a more balanced approach, focusing on maintaining the desired chromium content while minimizing porosity.

Understanding the specific HVOF parameters for WC12Co/WC10Co4Cr powders is crucial for achieving the desired performance in end products. These factors can be influenced by the equipment used, the substrate material, and the desired coating properties. By optimizing these parameters, manufacturers can tailor the tungsten carbide coatings to meet the stringent demands of various industrial applications, ultimately improving efficiency, productivity, and component longevity.

(Tungsten Carbide Powder WC12Co/WC10Co4Cr Powder for HVOF)

FAQs of Tungsten Carbide Powder WC12Co/WC10Co4Cr Powder for HVOF

Inquiry us