Overview of Top-quality Spherical Niobium Metal Powder for Thermal Protection Material and Structural Material

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Top-quality Spherical Niobium Metal Powder for Thermal Protection Material and Structural Material

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Top-quality Spherical Niobium Metal Powder for Thermal Protection Material and Structural Material)

Parameters of Top-quality Spherical Niobium Metal Powder for Thermal Protection Material and Structural Material

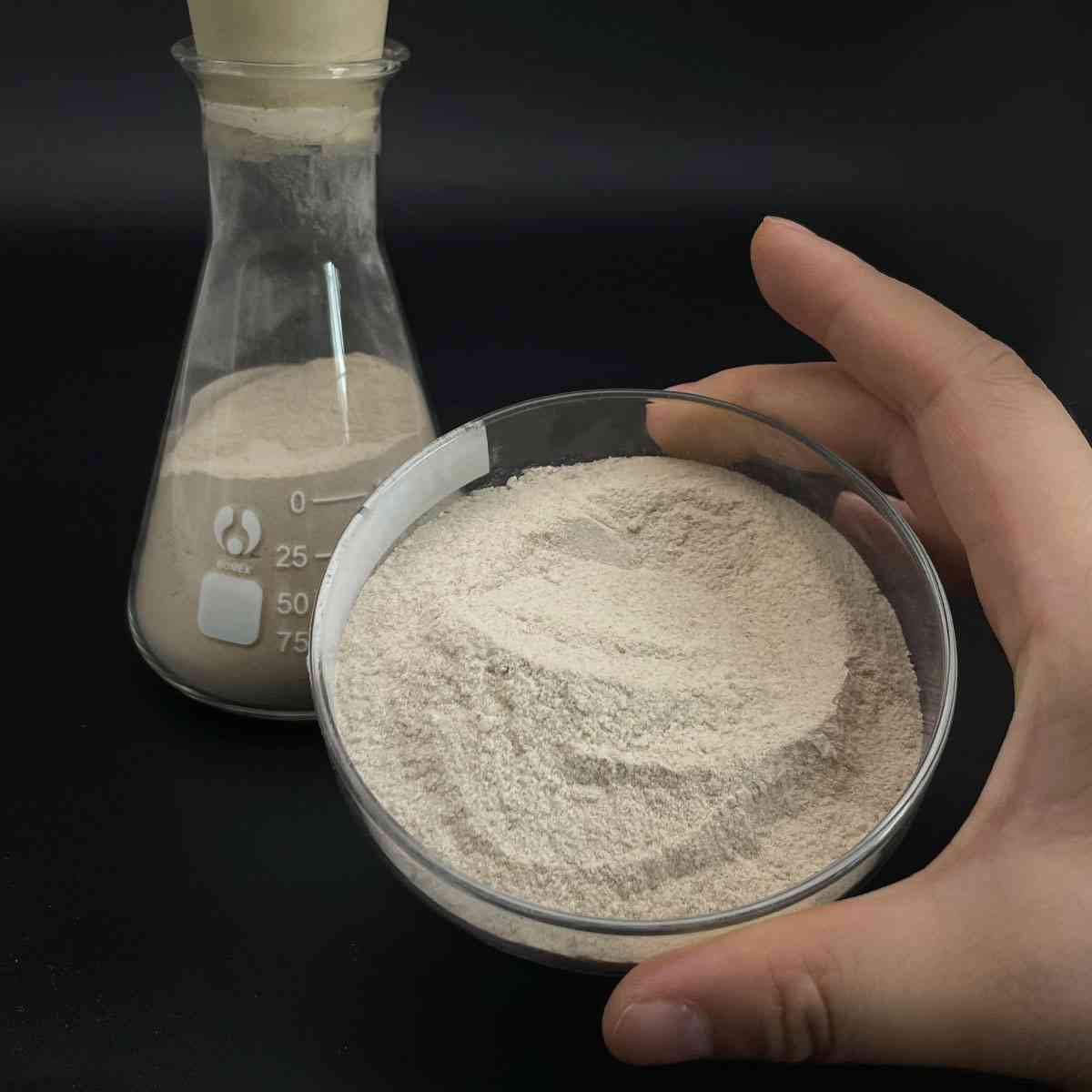

Spherical Niobium Metal Powder: A High-Performance Solution for Advanced Thermal and Structural Applications

Niobium, a chemical element with the symbol Nb and atomic number 41, is a versatile metallic material known for its exceptional properties that make it an ideal choice for various applications, particularly in thermal protection and structural components. The spherical niobium metal powder we offer is a premium grade material characterized by superior performance, purity, and consistency.

Firstly, our spherical niobium metal powder boasts an almost flawless microstructure, thanks to its unique manufacturing process that ensures uniform particle size distribution. This results in enhanced reactivity during melting and sintering, leading to better mechanical properties and reduced porosity in the final product. The spherical shape also minimizes surface area to volume ratio, facilitating even heat dissipation and improved thermal conductivity.

In thermal protection applications, such as rocket nozzles, heat shields, and aerospace components, this powder plays a critical role. Its high melting point (2750°C) and low coefficient of thermal expansion make it an outstanding choice for withstanding extreme temperatures without deformation. The excellent thermal stability of spherical niobium reduces thermal stress and prevents thermal shock, thereby extending the life of components subjected to high heat fluxes.

Structural materials benefit from the exceptional strength-to-weight ratio of spherical niobium metal powder. It exhibits excellent mechanical properties like high yield strength, ductility, and toughness, making it suitable for lightweight yet strong components in various industries, including automotive, aerospace, and energy production. The powder’s high purity ensures minimal impurities, which can compromise the integrity of the final product and improve the overall performance of the structures.

Furthermore, the spherical shape facilitates compaction and densification during the manufacturing process, leading to a more consistent and dense material. This translates into better dimensional accuracy and improved mechanical performance in the finished parts. Additionally, the powder’s high purity allows for better bonding during sintering, resulting in fewer voids and improved material utilization.

Processing advantages include ease of mixing with other metals or ceramics, allowing for the creation of composite materials with tailored properties. The spherical nature of the niobium metal powder ensures a more efficient consolidation process, reducing the need for complex shaping techniques and minimizing waste.

In summary, our top-quality spherical niobium metal powder is a game-changer for engineers and manufacturers seeking high-performance thermal protection and structural materials. Its unique characteristics, such as uniform particle size, high melting point, and excellent mechanical properties, make it an indispensable component in a wide range of industries where reliability, durability, and efficiency are paramount. With its versatility and superior performance, spherical niobium metal powder stands out as a key enabler for innovative designs and advancements in modern technology.

(Top-quality Spherical Niobium Metal Powder for Thermal Protection Material and Structural Material)

FAQs of Top-quality Spherical Niobium Metal Powder for Thermal Protection Material and Structural Material

Inquiry us