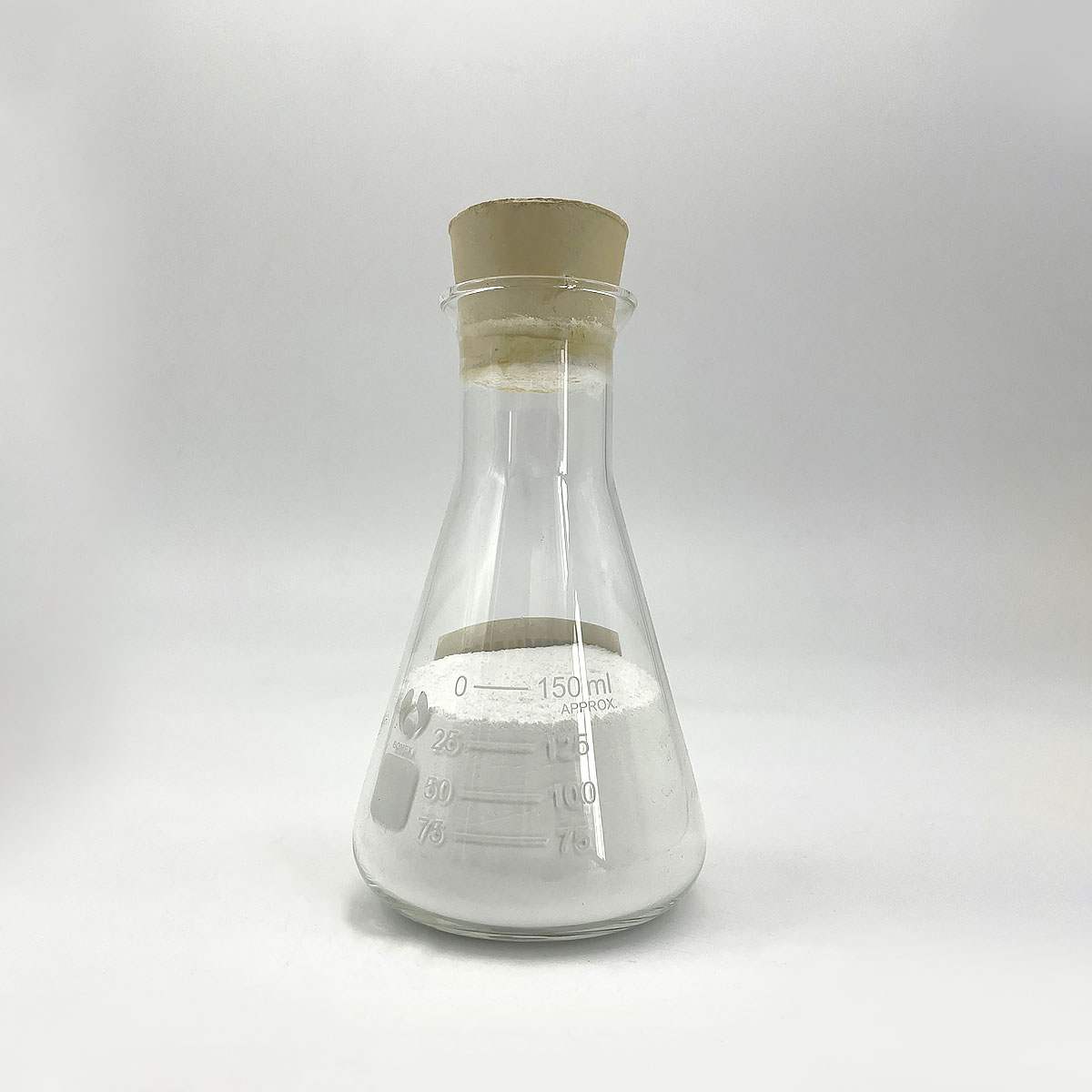

Overview of Supply TiN Titanium Nitride nanopowder for Low Radiation Glass Coating

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Supply TiN Titanium Nitride nanopowder for Low Radiation Glass Coating

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Supply TiN Titanium Nitride nanopowder for Low Radiation Glass Coating)

Parameters of Supply TiN Titanium Nitride nanopowder for Low Radiation Glass Coating

Titanium Nitride (TiN) nanopowder is a high-performance material with exceptional properties, particularly when it comes to low radiation glass coating applications. This advanced ceramic compound finds its way in various industries, including optoelectronics, aerospace, and automotive, due to its unique combination of wear resistance, thermal stability, and excellent adherence to surfaces.

TiN nanoparticles have a particle size ranging from submicron to nanoscale, providing a large surface-to-volume ratio, which enhances the coating’s effectiveness. When incorporated into glass coatings, these particles act as a barrier against harmful radiation, such as ultraviolet (UV) and infrared (IR) rays, while also improving the overall durability and scratch resistance of the glass.

The coating process typically involves the use of physical vapor deposition (PVD), chemical vapor deposition (CVD), or sol-gel techniques. In PVD, a titanium target is bombarded with nitrogen gas at high temperatures, resulting in the formation of TiN nanoparticles. These particles adhere to the glass substrate, forming a uniform and thin layer with excellent optical properties.

To optimize the coating parameters for low radiation glass, several factors must be considered:

1. Deposition temperature: Maintaining an optimal temperature is crucial for achieving a dense and adherent film. Lower temperatures may result in less stress on the glass, but higher temperatures can enhance the nucleation rate and improve film quality.

2. Pressure: The nitrogen pressure during the deposition process affects the growth rate and particle size. A controlled pressure ensures the formation of uniform TiN nanoparticles without compromising the film’s integrity.

3. Substrate preparation: Proper cleaning and surface treatment of the glass are vital to ensure a strong bond between the TiN coating and the substrate. This may involve etching or plasma treatment to remove contaminants and create a reactive surface.

4. Deposition rate: The speed at which the TiN nanoparticles are deposited onto the glass influences the thickness and uniformity of the coating. A balance must be struck to prevent defects and maintain the desired level of radiation protection.

5. Composition and purity: High-purity TiN nanopowder with a consistent stoichiometry ensures a homogeneous coating with optimal radiation-blocking properties. Contaminants can degrade the performance of the coating.

6. Annealing: Post-deposition annealing can help relieve internal stresses, improve film crystallinity, and further enhance the coating’s durability and radiation resistance.

In conclusion, using TiN nanopowder in low radiation glass coating applications requires careful consideration of deposition parameters to achieve the best possible results. By optimizing these factors, manufacturers can create glass products with superior protection against harmful radiation while maintaining the necessary transparency and aesthetics for various industries. The future holds promise for continued advancements in TiN technology, enabling even more innovative and efficient solutions for radiation shielding in glass applications.

(Supply TiN Titanium Nitride nanopowder for Low Radiation Glass Coating)

FAQs of Supply TiN Titanium Nitride nanopowder for Low Radiation Glass Coating

Inquiry us