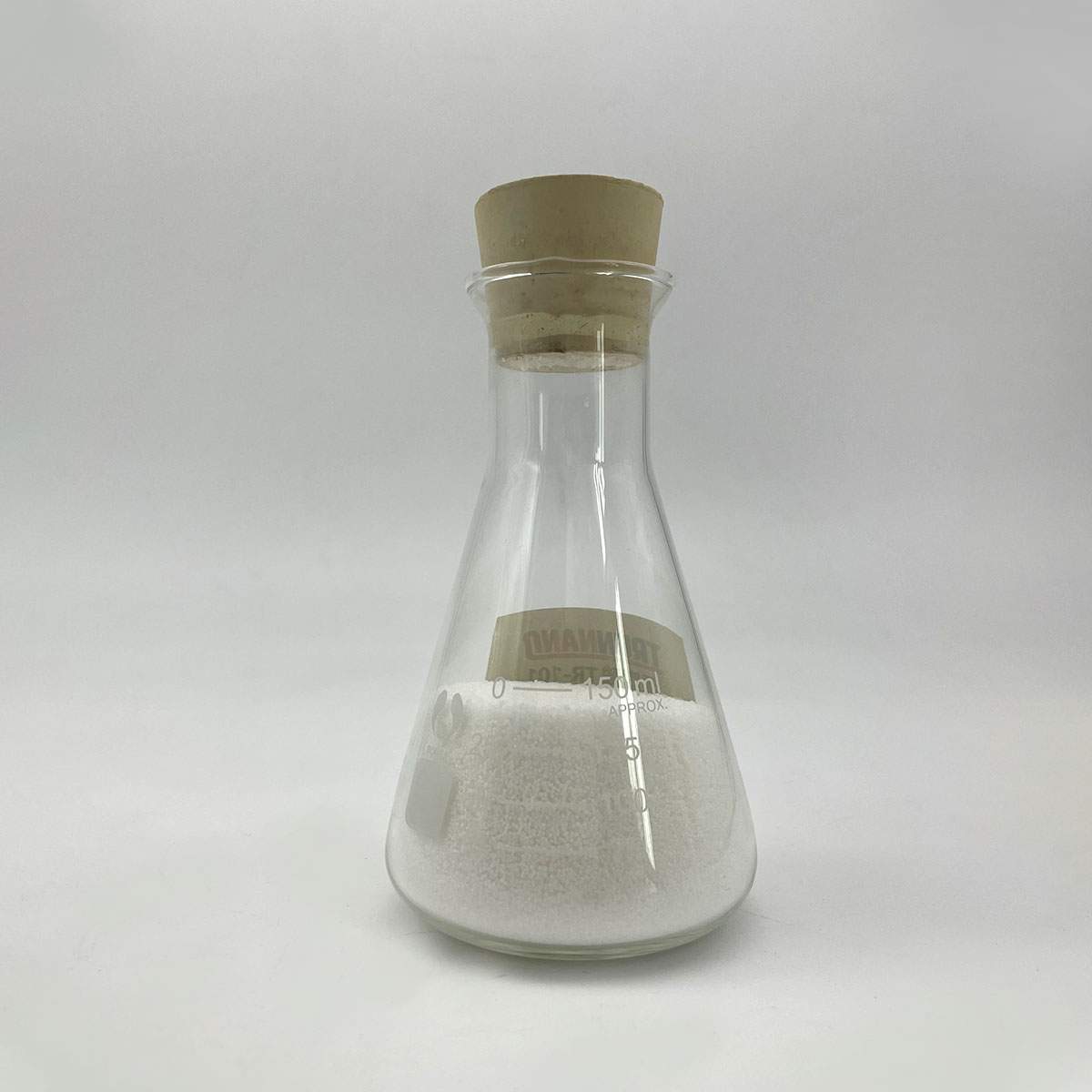

Overview of Spherical Tantalum Powder for additive manufacturing 3D printing Ta Powder 99.95% purity

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Spherical Tantalum Powder for additive manufacturing 3D printing Ta Powder 99.95% purity

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Spherical Tantalum Powder for additive manufacturing 3D printing Ta Powder 99.95% purity)

Parameters of Spherical Tantalum Powder for additive manufacturing 3D printing Ta Powder 99.95% purity

Spherical Tantalum Powder, also known as Ta Powder or tantalum metal particles with a 99.95% purity, is a high-performance material specifically designed for advanced applications in additive manufacturing, particularly 3D printing. This cutting-edge powder form is tailored to meet the stringent requirements of modern 3D printing technologies, such as selective laser melting (SLM), electron beam melting (EBM), and other direct metal laser sintering (DMLS) processes.

Tantalum, an incredibly dense and corrosion-resistant transition metal, boasts exceptional mechanical properties like high strength, low thermal expansion, and excellent wear resistance. It is known for its ability to maintain its shape under extreme conditions, making it suitable for aerospace, automotive, medical, and defense industries where reliability and durability are paramount.

The spherical shape of the tantalum powder offers several advantages over other particle geometries. Spherical particles ensure more consistent packing density, reducing voids and improving print resolution during the build process. The uniform size distribution ensures better flowability, facilitating accurate layer-by-layer deposition and minimizing the formation of defects. This leads to enhanced part integrity and reduced post-processing time.

The 99.95% purity level indicates that the powder contains minimal impurities, which is crucial for achieving high-quality prints with predictable and repeatable properties. A higher purity grade reduces the risk of contamination and improves the overall performance of the printed components.

In terms of processing, the lack of any specific format makes this tantalum powder versatile and adaptable to various 3D printing systems. Users can adjust parameters like laser power, scanning speed, and layer height according to their printer’s specifications and desired outcome. This flexibility allows for customization and optimization of the printing process to achieve optimal results for different applications.

When incorporating spherical tantalum powder into 3D printing, it is essential to maintain proper handling and storage procedures to preserve its purity and integrity. This includes using cleanroom-grade equipment and avoiding exposure to moisture, air contaminants, and static electricity, which can negatively impact the quality of the final product.

In summary, spherical tantalum powder with 99.95% purity is a game-changer in additive manufacturing, offering unparalleled performance, precision, and versatility. Its unique properties, combined with its suitability for various 3D printing techniques, make it a sought-after material for industries demanding high-strength, corrosion-resistant components in demanding environments. As technology continues to advance, the use of this premium Ta powder will undoubtedly open up new possibilities for innovation and design in numerous sectors.

(Spherical Tantalum Powder for additive manufacturing 3D printing Ta Powder 99.95% purity)

FAQs of Spherical Tantalum Powder for additive manufacturing 3D printing Ta Powder 99.95% purity

Inquiry us