Overview of Niobium powder plate blank cube/Customized Niobium Titanium Alloy (Nb-Ti) Round powder Pure Niobium Powders

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Niobium powder plate blank cube/Customized Niobium Titanium Alloy (Nb-Ti) Round powder Pure Niobium Powders

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Niobium powder plate blank cube/Customized Niobium Titanium Alloy (Nb-Ti) Round powder Pure Niobium Powders)

Parameters of Niobium powder plate blank cube/Customized Niobium Titanium Alloy (Nb-Ti) Round powder Pure Niobium Powders

Niobium, a chemical element with the symbol Nb and atomic number 41, is a unique metallic material known for its exceptional properties. It belongs to the transition metal group and is primarily found in the mineral columbite. Niobium’s titanium alloy, commonly referred to as Nb-Ti or Niobium Titanium Alloys, combines the best attributes of both elements, resulting in a versatile material that finds extensive applications across various industries.

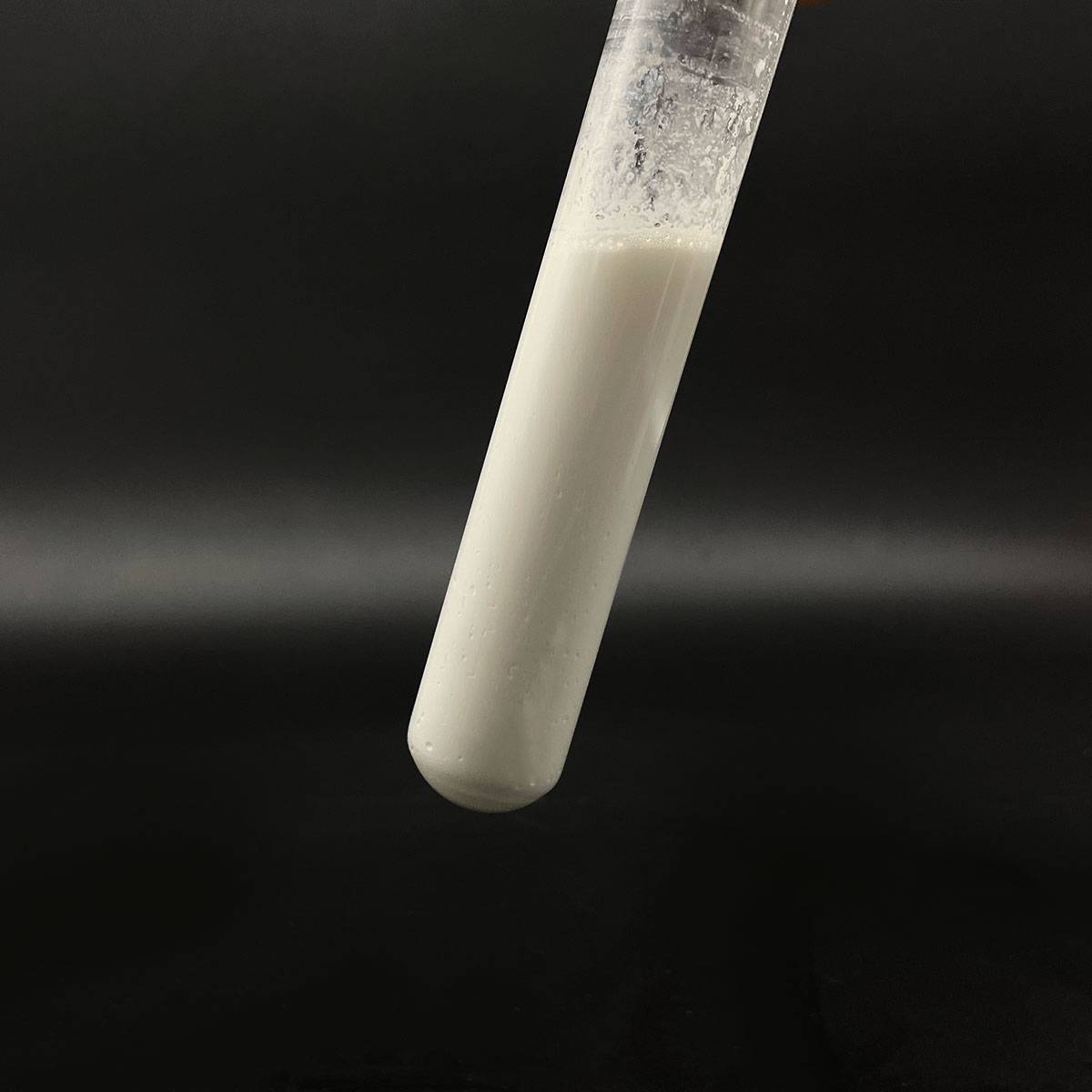

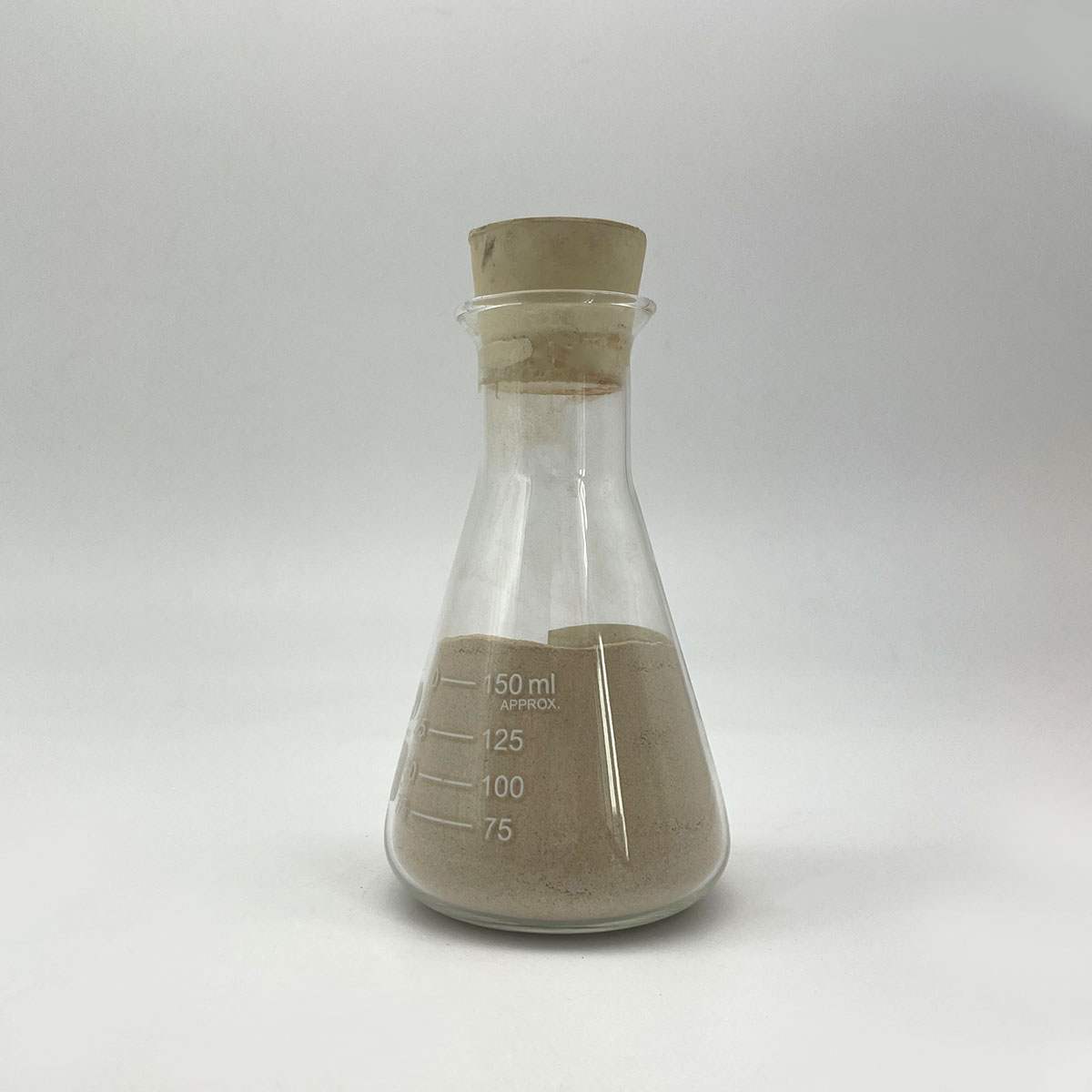

Pure niobium powders are derived from high-purity niobium ingots through a process of refining, melting, and subsequent particle size reduction. These powders are available in different grades, depending on the purity, particle size distribution, and morphology required for specific applications. The powders can be spherical, submicron, or nanoscale, enabling customization for diverse manufacturing techniques such as additive manufacturing, sintering, and casting.

One of the key features of niobium is its low thermal expansion coefficient, making it an excellent choice for temperature-sensitive applications. Its high strength-to-weight ratio and good corrosion resistance make it suitable for aerospace, nuclear, and medical industries. Niobium Ti alloys, in particular, exhibit enhanced mechanical properties, improved machinability, and better creep resistance compared to pure niobium.

The ability to form a strong and ductile intermetallic phase when combined with titanium makes Nb-Ti an attractive material for cryogenic applications, where it can withstand extremely low temperatures without losing its structural integrity. This property is crucial in the construction of superconducting magnets, used in MRI machines and particle accelerators.

Moreover, niobium has a high electrical conductivity, which qualifies it for use in electromagnetic shielding and microwave components. Its superconducting behavior below a critical temperature makes it an essential material in high-tech devices like SQUIDs (Superconducting Quantum Interference Devices) for sensitive magnetic field detection.

When it comes to processing, niobium powders offer versatility due to their wide range of particle sizes and shapes. They can be compacted into dense structures through processes like hot pressing or cold compaction, forming blanks or plates. These blanks can then be further machined into cubes or custom shapes according to customer requirements. The powder metallurgy technique allows for intricate geometries and reduced porosity, enhancing the overall performance of the final product.

In summary, niobium and its alloys, especially Nb-Ti, are highly sought-after materials due to their unique combination of properties, including low thermal expansion, high strength, and excellent electrical conductivity. Their availability in powder form enables customization, making them suitable for various applications in industries ranging from aerospace to electronics. With ongoing research and development, niobium continues to find new frontiers in technology, driven by its inherent capabilities and the potential for further material improvements.

(Niobium powder plate blank cube/Customized Niobium Titanium Alloy (Nb-Ti) Round powder Pure Niobium Powders)

FAQs of Niobium powder plate blank cube/Customized Niobium Titanium Alloy (Nb-Ti) Round powder Pure Niobium Powders

Inquiry us