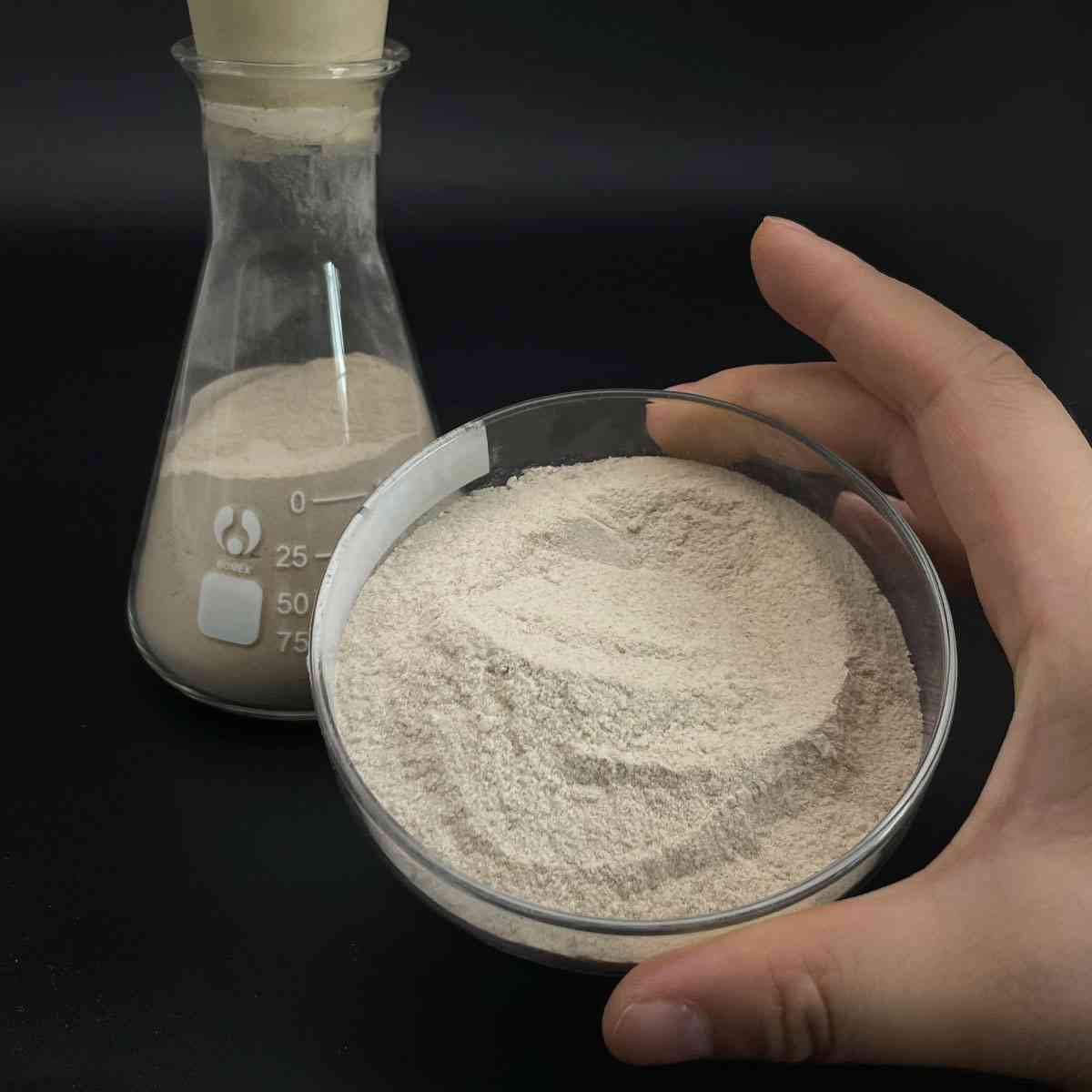

Overview of Niobite ferro-niobium fenb alloy metal fenb50 powder 65 nb HRNB good quality ferro niobium fenb ferroniobium powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Niobite ferro-niobium fenb alloy metal fenb50 powder 65 nb HRNB good quality ferro niobium fenb ferroniobium powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Niobite ferro-niobium fenb alloy metal fenb50 powder 65 nb HRNB good quality ferro niobium fenb ferroniobium powder)

Parameters of Niobite ferro-niobium fenb alloy metal fenb50 powder 65 nb HRNB good quality ferro niobium fenb ferroniobium powder

Ferro-Niobium Ferb (FeNbF) is a unique metallic compound that exhibits exceptional properties, particularly when it comes to the Niobite-Fenb50 alloy. This high-quality material, with a composition of approximately 65% Niobium (Nb), 35% Ferro-Boron (FeB), and a small percentage of Ferroniobium (FeNb), has garnered significant attention in various industrial applications due to its outstanding characteristics.

The primary feature of Ferro-Niobium Ferb is its excellent mechanical strength. It possesses high yield strength and tensile strength, making it suitable for demanding structural components where durability and resistance to deformation are crucial. The addition of Ferro-Boron enhances the material’s hardness, wear resistance, and creep resistance, which are essential traits for applications under extreme conditions.

In terms of thermal stability, Ferro-Niobium Ferb displays remarkable heat resistance, maintaining its integrity over a wide temperature range. This property makes it ideal for use in high-temperature environments, such as aerospace, nuclear power, and chemical processing industries, where materials need to withstand elevated temperatures without degrading.

Another standout characteristic of this alloy is its magnetic properties. Although not a conventional ferromagnetic material, Ferro-Niobium Ferb exhibits moderate magnetic behavior, which can be advantageous in certain electromagnetic applications, like transformers or magnetic shielding components.

The microstructure of Ferro-Niobium Ferb is crucial for its performance. With a fine grain size, the powder form of this alloy (Fenb50 powder) ensures a homogenous distribution of elements and improved sintering properties. The high-purity HRNB (Highly Refractory Niobium Boride) grade further enhances its purity and reduces impurities, resulting in superior mechanical and functional properties.

In terms of processing, the Ferro-Niobium Ferb powder is easy to handle and can be efficiently formed into various shapes and sizes through techniques like sintering, casting, or powder metallurgy methods. Its compatibility with other metals and alloys also allows for easy integration into composite materials, expanding its application possibilities.

From an environmental perspective, Ferro-Niobium Ferb demonstrates low toxicity and minimal environmental impact, making it a sustainable choice for industries concerned about eco-friendliness. Additionally, its corrosion resistance ensures long-term service life, reducing maintenance requirements and overall costs.

In conclusion, the Ferro-Niobium Ferb alloy, specifically the Fenb50 powder with a 65% Nb and 35% FeB composition, is a high-performance material with exceptional mechanical, thermal, magnetic, and environmental attributes. Its versatility and ability to withstand harsh conditions make it a sought-after option in various sectors, including automotive, aerospace, and energy industries. As technology advances, the demand for this innovative material is expected to grow, driven by its potential to improve efficiency and sustainability in numerous applications.

(Niobite ferro-niobium fenb alloy metal fenb50 powder 65 nb HRNB good quality ferro niobium fenb ferroniobium powder)

FAQs of Niobite ferro-niobium fenb alloy metal fenb50 powder 65 nb HRNB good quality ferro niobium fenb ferroniobium powder

Inquiry us