Overview of Naseiko ESP-30S mass-production tungsten carbide powder compaction press 30 ton force electronic servo press machine for powder

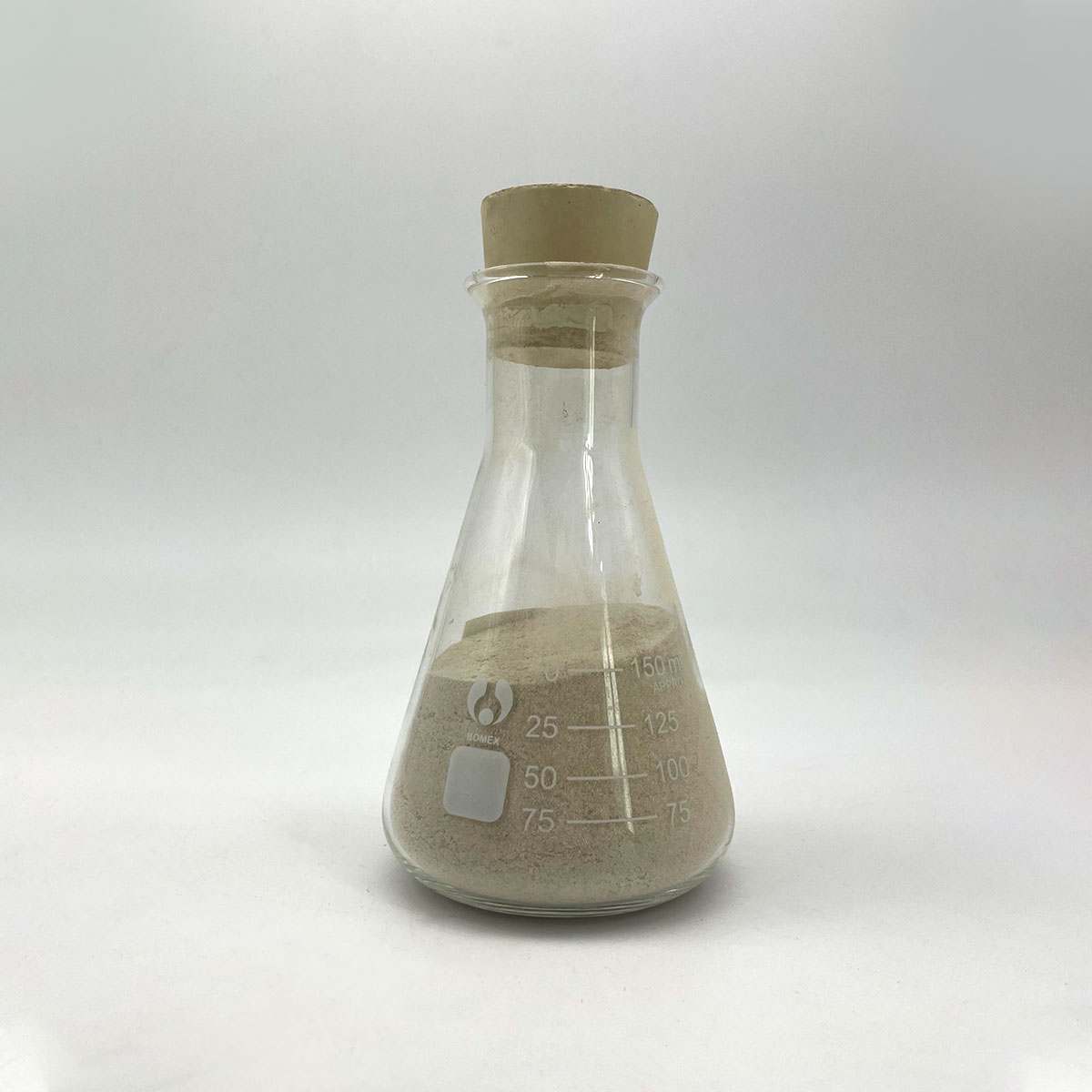

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Naseiko ESP-30S mass-production tungsten carbide powder compaction press 30 ton force electronic servo press machine for powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Naseiko ESP-30S mass-production tungsten carbide powder compaction press 30 ton force electronic servo press machine for powder)

Parameters of Naseiko ESP-30S mass-production tungsten carbide powder compaction press 30 ton force electronic servo press machine for powder

The Naseiko ESP-30S is a state-of-the-art, high-performance mass-production tungsten carbide powder compaction press designed to deliver exceptional precision and efficiency in the manufacturing process. This cutting-edge electronic servo press machine, boasting a staggering 30-ton force capacity, is specifically engineered for compacting tungsten carbide powders with unparalleled accuracy.

Equipped with advanced electronic servo technology, the ESP-30S ensures precise control over the compression force, minimizing waste and maximizing the density of the final product. The electronic system enables real-time monitoring and adjustments, allowing for consistent and repeatable results across large production runs. The machine’s servo drive system provides smooth, energy-efficient operation, reducing operational costs and minimizing environmental impact.

The design of the ESP-30S is optimized for compacting tungsten carbide powders due to their inherent properties, ensuring that the particles are tightly packed and bonded together without any voids or defects. The compacted parts exhibit outstanding mechanical strength, wear resistance, and thermal stability, making them ideal for applications in industries such as automotive, aerospace, and industrial machinery.

The press’s massive 30-ton force capacity allows for handling a wide range of tungsten carbide powder particle sizes, accommodating various compaction pressures required by different applications. The press bed, constructed from robust materials, can accommodate large molds and dies, further enhancing its versatility in meeting diverse customer requirements.

Safety features are of paramount importance in the ESP-30S, with built-in safety interlocks, emergency stop buttons, and automatic overload protection systems. These measures ensure the well-being of operators while maintaining productivity and preventing accidents during the pressing process.

In summary, the Naseiko ESP-30S tungsten carbide powder compaction press is a technologically advanced, high-force, and highly efficient machine that revolutionizes the way tungsten carbide powders are compacted into dense, high-quality components. Its precision, reliability, and adaptability make it an indispensable tool for manufacturers seeking to streamline their processes and produce top-notch products in demanding industries. With its combination of electronic servo control, force accuracy, and ergonomic design, the ESP-30S sets a new benchmark in the field of tungsten carbide manufacturing.

(Naseiko ESP-30S mass-production tungsten carbide powder compaction press 30 ton force electronic servo press machine for powder)

FAQs of Naseiko ESP-30S mass-production tungsten carbide powder compaction press 30 ton force electronic servo press machine for powder

Inquiry us