Overview of Nano Tungsten oxide WO3 powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Nano Tungsten oxide WO3 powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

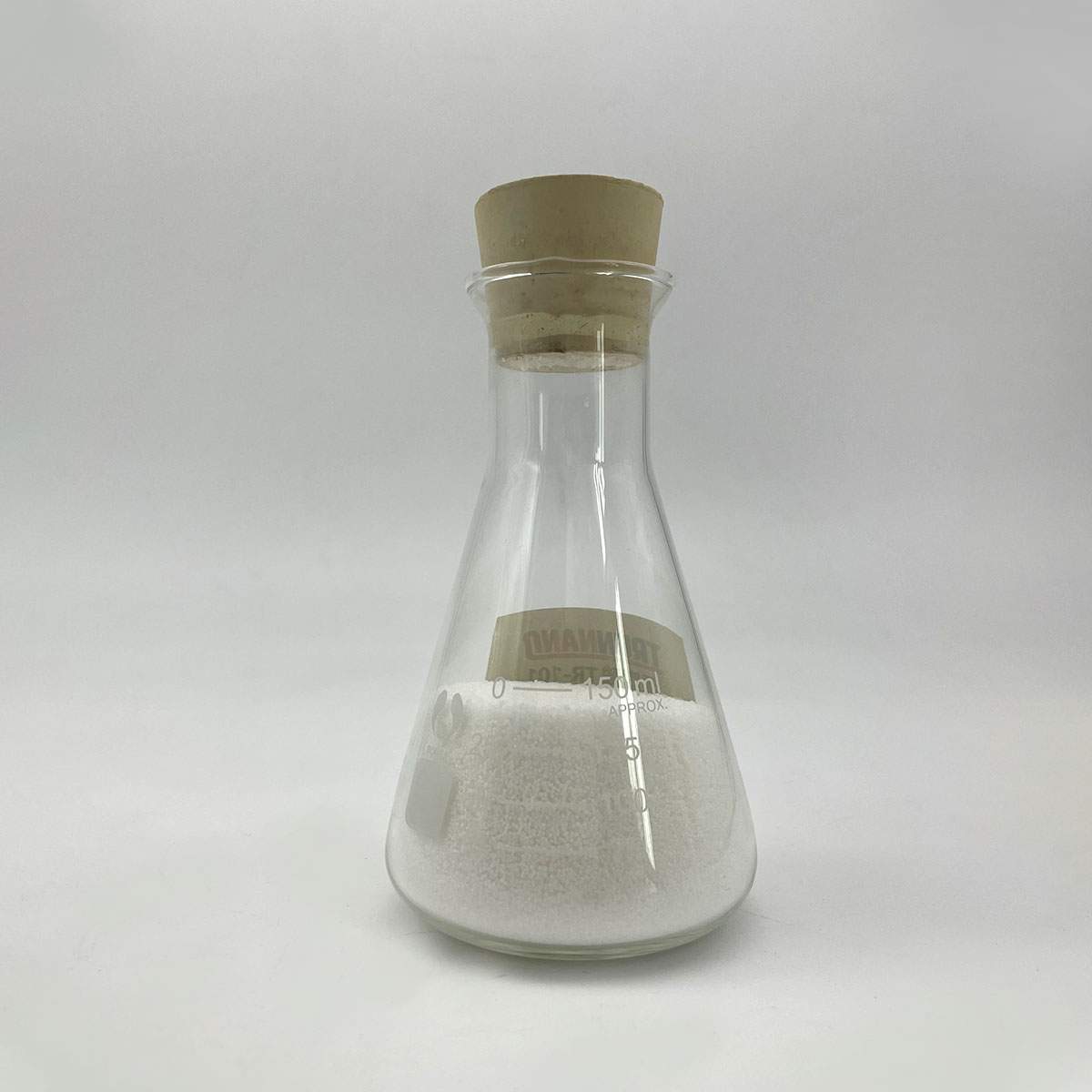

(Nano Tungsten oxide WO3 powder )

Parameters of Nano Tungsten oxide WO3 powder

Tungsten oxide, also known as WO3 or Nano Tungsten Trioxide, is a highly versatile and technologically advanced material that has gained significant attention in various industries due to its unique properties. This nanoscale form of tungsten oxide exhibits exceptional characteristics that set it apart from its bulk counterparts.

The primary component of Nano WO3 is tungsten, which is a chemical element with the atomic number 74 and symbol W. It is a hard, lustrous metal known for its high melting point (3410°C) and excellent thermal stability. When combined with oxygen, it forms the oxide compound, tungsten trioxide. The structure of this compound consists of tungsten atoms bonded with oxygen atoms, forming a trigonal pyramidal arrangement.

In the nanoform, the particle size reduction significantly impacts the material’s properties. Nano WO3 particles have dimensions ranging from a few nanometers to a hundred nanometers, offering a much larger surface area per unit mass compared to conventional WO3. This increased surface area enhances reactivity, making it ideal for catalytic applications and facilitating improved electrochemical performance.

One of the key features of Nano WO3 is its photocatalytic activity. Under UV light, it can decompose pollutants and organic compounds into harmless byproducts, such as water and oxygen. This makes it an attractive choice for air purification systems, water treatment, and environmental remediation efforts.

Moreover, the nanostructured WO3 possesses high electrical conductivity, particularly when doped with other elements like niobium or tantalum. This property makes it suitable for use in thin-film transistors, solar cells, and lithium-ion batteries, where its enhanced charge transport capabilities contribute to better device performance.

In the field of electronics, Nano WO3 is employed in sensors, especially gas sensors, due to its sensitivity to changes in chemical composition. Its ability to detect specific gases at low concentrations makes it valuable in safety and environmental monitoring applications.

In the field of energy storage, Nano WO3 finds applications in supercapacitors and lithium-ion batteries. Its high capacitance and good cycle stability make it an effective electrode material, contributing to the development of advanced energy storage devices.

Additionally, Nano WO3 is used in the production of pigments and coatings. Its white, bright, and translucent nature makes it a popular choice for paint, varnish, and ceramic glazes, imparting a unique sheen and opacity.

However, the synthesis and processing of Nano WO3 present challenges, such as controlling particle size and morphology, ensuring uniformity, and maintaining the desired properties during handling. Various techniques, including sol-gel, hydrothermal, and chemical vapor deposition, are employed to produce high-quality Nano WO3 powders.

In conclusion, Nano Tungsten Oxide WO3 is a remarkable material with a myriad of applications across different sectors, from environmental remediation to electronic devices. Its unique properties, derived from its nanoscale structure, make it an essential component in modern technology and sustainable solutions. As research continues to advance, the potential uses and benefits of Nano WO3 are likely to expand even further.

(Nano Tungsten oxide WO3 powder )

FAQs of Nano Tungsten oxide WO3 powder

Inquiry us