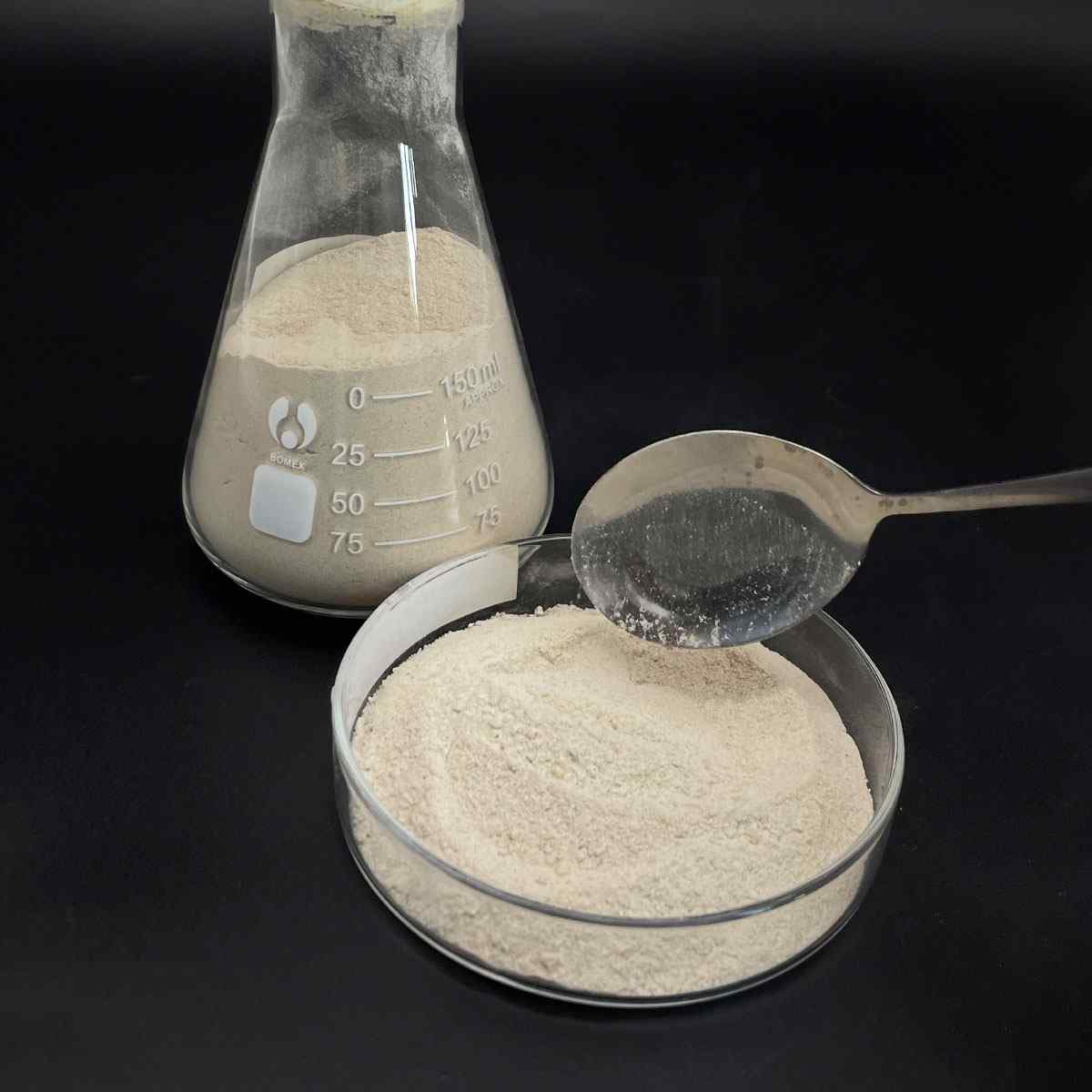

Overview of Molybdenum Powder for Spraying Coating Hardfacing Metallurgy Welding

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Molybdenum Powder for Spraying Coating Hardfacing Metallurgy Welding

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Molybdenum Powder for Spraying Coating Hardfacing Metallurgy Welding)

Parameters of Molybdenum Powder for Spraying Coating Hardfacing Metallurgy Welding

Molybdenum powder, a high-performance metallic material, is widely used in various industrial applications, particularly in the field of hardfacing and welding processes due to its exceptional properties like high melting point, wear resistance, and excellent thermal conductivity. When it comes to spraying coatings for hardfacing metallurgy and welding, the selection of appropriate parameters plays a crucial role in achieving optimal results and ensuring the longevity of the components.

Hardfacing is a technique employed to reinforce or restore worn surfaces on metal parts by depositing a layer of a harder, more wear-resistant material. Molybdenum-based powders, such as MoWCu (molybdenum tungsten carbide) or MoNi (molybdenum nickel), are popular choices due to their superior hardness and resistance to abrasive wear.

The welding parameters for molybdenum powder spraying include:

1. **Material Selection**: Choose the right molybdenum alloy based on the specific application’s requirements. For instance, MoWCu is ideal for heavy-duty applications, while MoNi is suitable for lighter loads with better machinability.

2. **Powder Size**: The particle size influences the coating’s porosity, adhesion, and flow characteristics. Smaller particles result in a finer, more even coating, but they may require higher welding currents. Opt for a particle size between 40-120 microns, depending on the equipment and desired finish.

3. **Gas Flow**: The gas mixture (usually a combination of argon and hydrogen) controls the powder flow and affects the coating’s quality. A proper balance is essential to achieve good adhesion and minimize spatter. Adjust the gas flow rate to ensure a consistent powder feed.

4. **Welding Voltage**: Higher voltage settings can produce a higher arc energy, promoting better powder melting and deposition. However, excessive voltage can lead to excessive spattering. Experiment to find the optimal voltage for your specific setup and application.

5. **Current**: The welding current determines the heat input and affects the coating’s hardness and density. Generally, a higher current will result in a thicker coating, while lower currents provide better detail and surface finish. Choose a current that ensures a good bond without overheating the substrate.

6. **Travel Speed**: Slower travel speeds allow for better powder flow and denser coatings, but they can also increase the risk of overheating. Aim for a speed that balances quality and efficiency, typically between 200-400 mm/min.

7. **Layer Thickness**: The number of layers and their thickness should be adjusted to achieve the desired hardness and wear resistance. Thinner layers can result in better surface finish, while thicker ones offer better mechanical strength.

8. **Cooling Strategy**: After each pass, proper cooling is crucial to prevent cracking and maintain the integrity of the coating. Use water cooling, air, or a combination of both, depending on the equipment and material.

9. **Post-Weld Treatment**: After hardfacing, it’s essential to perform post-processing, such as grinding or machining, to achieve the required surface finish and dimensional accuracy.

In conclusion, selecting the right welding parameters for molybdenum powder in hardfacing metallurgy requires careful consideration of the material, equipment, and application specifics. By optimizing these factors, you can achieve a robust, wear-resistant coating that enhances the durability and performance of the component.

(Molybdenum Powder for Spraying Coating Hardfacing Metallurgy Welding)

FAQs of Molybdenum Powder for Spraying Coating Hardfacing Metallurgy Welding

Inquiry us