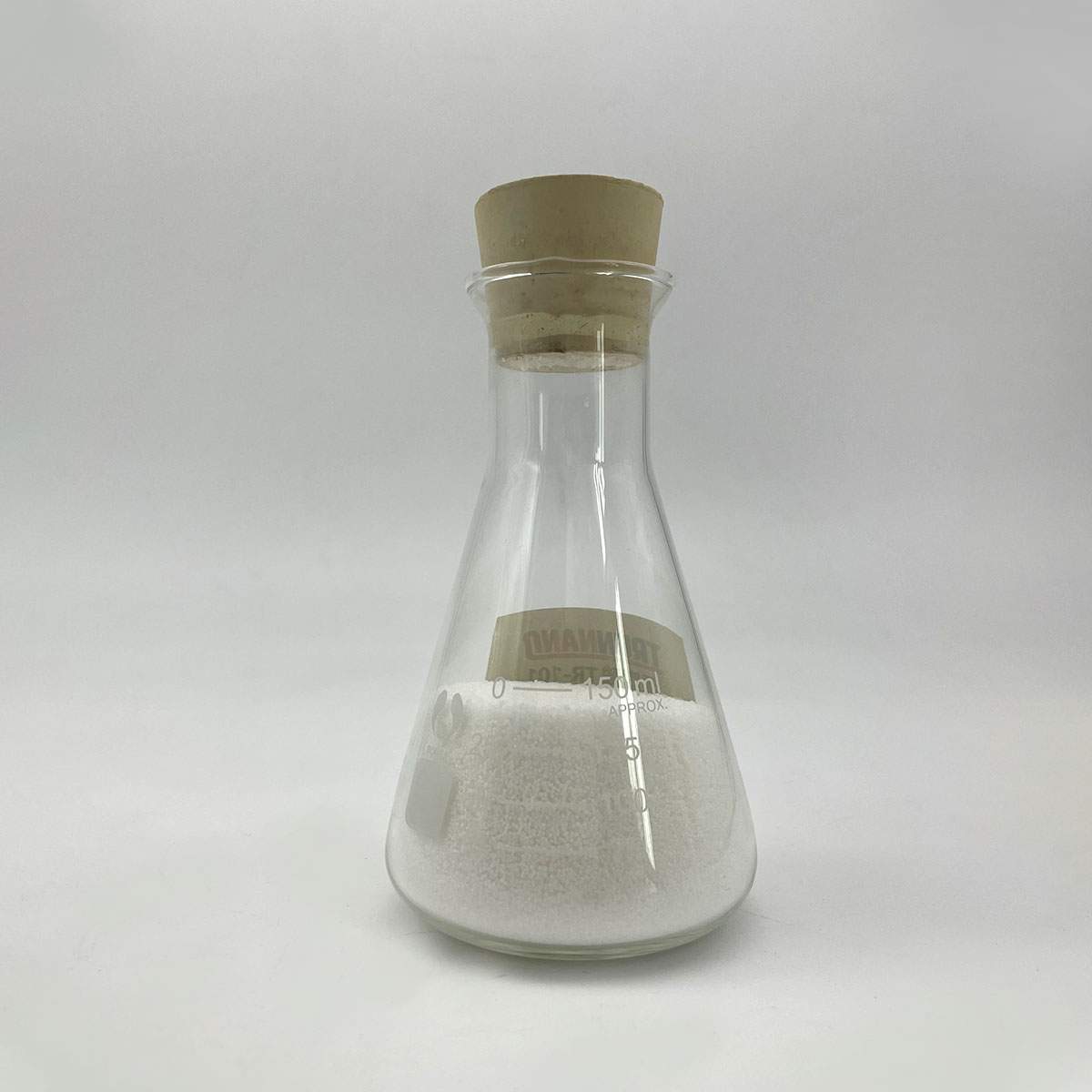

Overview of Maximum phase Mo3AlC2 powder Molybdenum aluminum carbide per kg

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Maximum phase Mo3AlC2 powder Molybdenum aluminum carbide per kg

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Maximum phase Mo3AlC2 powder Molybdenum aluminum carbide per kg)

Parameters of Maximum phase Mo3AlC2 powder Molybdenum aluminum carbide per kg

Molybdenum aluminum carbide, also known as Mo3AlC2, is a high-performance ceramic material that has gained significant attention in various industries due to its unique combination of properties. This compound exhibits exceptional strength, thermal stability, and wear resistance, making it an ideal candidate for applications requiring durability and performance under extreme conditions.

Per kilogram of Mo3AlC2 powder, several key parameters are noteworthy. Firstly, the density is typically around 3.3 to 3.5 grams per cubic centimeter (g/cm³), which is relatively high compared to most metals but lower than some other ceramics. This density contributes to its lightweight nature without compromising strength, making it suitable for aerospace and automotive industries where weight reduction is critical.

The particle size distribution plays a crucial role in the material’s performance. Mo3AlC2 powders are often produced with a narrow size range, ensuring consistent and predictable processing properties. A typical particle size can vary from submicron to a few micrometers, allowing for better densification during sintering and facilitating the formation of a dense, homogeneous structure.

The microstructure of Mo3AlC2 is characterized by a hexagonal close-packed arrangement of molybdenum and aluminum atoms, with carbide (C) forming interstitial sites. This structure imparts excellent mechanical strength, with a high hardness and fracture toughness. The material exhibits low coefficient of thermal expansion, reducing the risk of dimensional instability during temperature fluctuations.

In terms of thermal properties, Mo3AlC2 has an exceptionally high melting point, ranging between 2800°C to 3000°C, making it resistant to heat and wear. It also possesses good thermal conductivity, which is beneficial for heat dissipation in electronic components or as a heat spreader.

Regarding chemical stability, Mo3AlC2 is relatively inert and resists corrosion in many environments. It is resistant to oxidation, alkalis, and certain acids, making it suitable for applications in harsh chemical environments, such as oil and gas exploration, and chemical processing.

Processing methods for Mo3AlC2 powder include spark plasma sintering (SPS), hot pressing, or conventional sintering techniques. These processes allow for precise control over the final properties, including grain size and porosity, which can be tailored to meet specific application requirements.

In conclusion, Mo3AlC2 powder offers a unique set of properties that make it an attractive material for a wide range of applications, including cutting tools, wear-resistant coatings, and structural components in high-temperature environments. Its high melting point, thermal stability, and excellent mechanical properties, combined with its lightweight nature, position it as a promising material for the future of advanced engineering technologies.

(Maximum phase Mo3AlC2 powder Molybdenum aluminum carbide per kg)

FAQs of Maximum phase Mo3AlC2 powder Molybdenum aluminum carbide per kg

Inquiry us