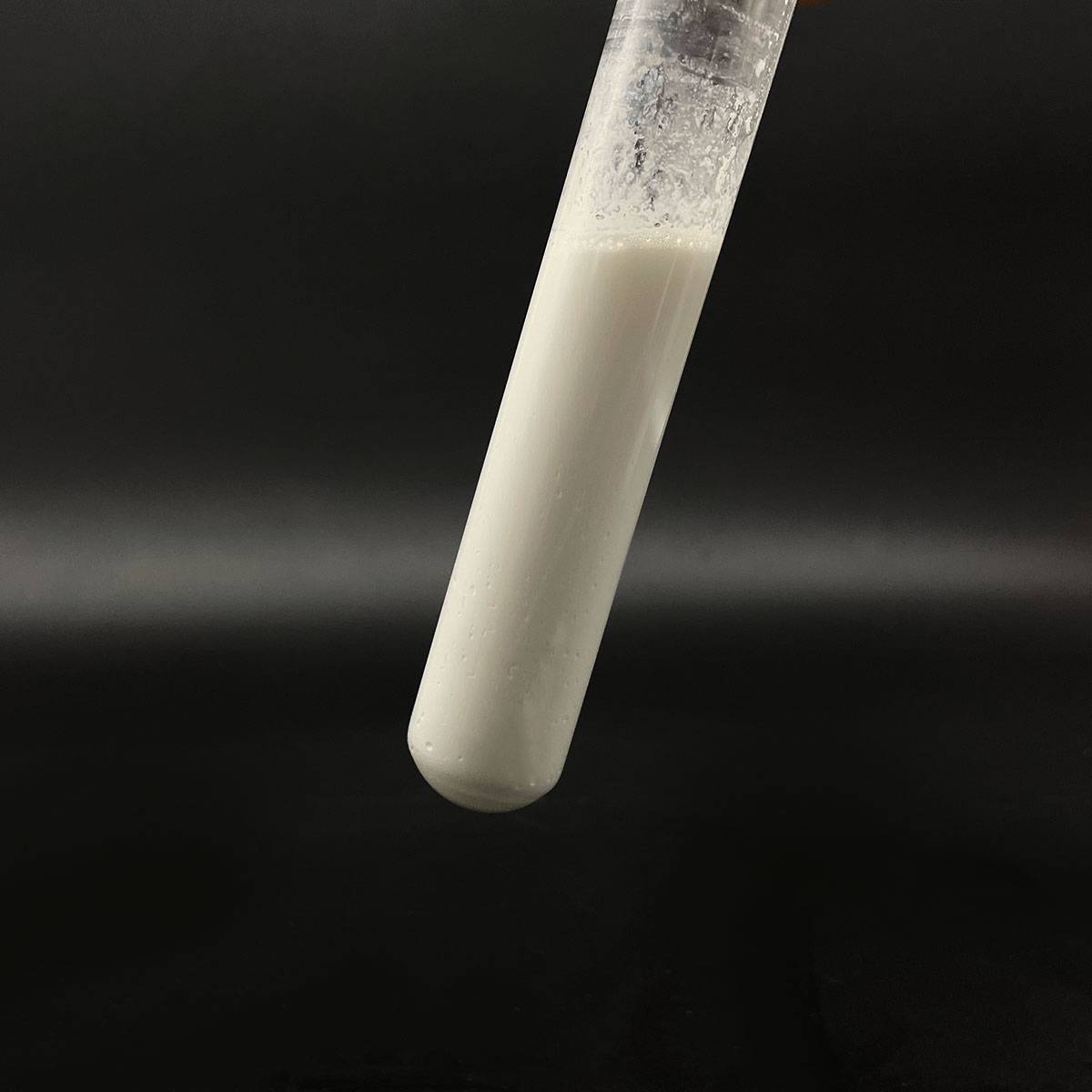

Overview of Max Phase Tantalum Aluminium Carbide Mxene 211 MAX Special Ceramics Material Tantalum Aluminium Carbide Ta2AlC powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Max Phase Tantalum Aluminium Carbide Mxene 211 MAX Special Ceramics Material Tantalum Aluminium Carbide Ta2AlC powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Max Phase Tantalum Aluminium Carbide Mxene 211 MAX Special Ceramics Material Tantalum Aluminium Carbide Ta2AlC powder)

Parameters of Max Phase Tantalum Aluminium Carbide Mxene 211 MAX Special Ceramics Material Tantalum Aluminium Carbide Ta2AlC powder

Max Phase Tantalum Aluminium Carbide (MXene) is a unique class of two-dimensional ceramic materials, specifically identified as MAX phases, with the chemical formula Ta2AlC. MXenes are derived from transition metal carbides and nitrides, and their extraordinary properties make them highly sought after in various industries, including electronics, aerospace, and energy storage.

Ta2AlC, also known as MAX211, is a layered material that consists of tantalum (Ta) and aluminium (Al) atoms bonded to carbon (C) atoms in a hexagonal arrangement. The structure resembles graphene, but with alternating layers of metal carbide and aluminium. This distinctive composition gives rise to exceptional mechanical, thermal, and electrical properties.

One of the most notable features of MXene is its high strength-to-weight ratio, which makes it an ideal material for lightweight applications. Ta2AlC possesses excellent mechanical stiffness, fracture toughness, and resistance to wear, making it suitable for use in components subjected to harsh environments or high stress conditions.

In terms of electrical conductivity, Ta2AlC exhibits both metallic and superconducting behavior, depending on the processing conditions. It can act as a promising material for electronic devices due to its low resistivity and high thermal conductivity, enabling efficient heat dissipation and improved device performance.

Moreover, Ta2AlC displays remarkable chemical stability, resisting corrosion in various chemical environments. This property makes it an attractive choice for applications in chemical processing, catalysis, and even biomedical implants where biocompatibility is crucial.

Another critical aspect of MXene is its ability to be easily exfoliated into thin, atomically thin layers through wet etching processes. This results in the formation of flexible films and nanosheets, opening up possibilities for applications in flexible electronics, sensors, and energy storage devices such as supercapacitors and batteries.

In the field of energy storage, Ta2AlC’s large surface area and fast ion transport make it a promising anode material for Li-ion batteries. Its high capacity retention and good rate capability promise to enhance battery performance and prolong battery life.

In conclusion, Max Phase Tantalum Aluminium Carbide (MXene) MAX211 is a cutting-edge ceramic material with exceptional properties that set it apart from conventional ceramics. Its unique combination of strength, conductivity, chemical stability, and processability makes it a versatile material with a wide range of potential applications in areas like aerospace, automotive, electronics, and energy storage. As research continues to unfold, we can expect further advancements in utilizing this extraordinary material in modern technology.

(Max Phase Tantalum Aluminium Carbide Mxene 211 MAX Special Ceramics Material Tantalum Aluminium Carbide Ta2AlC powder)

FAQs of Max Phase Tantalum Aluminium Carbide Mxene 211 MAX Special Ceramics Material Tantalum Aluminium Carbide Ta2AlC powder

Inquiry us