Overview of high quality pure molybdenum bar rod per kg

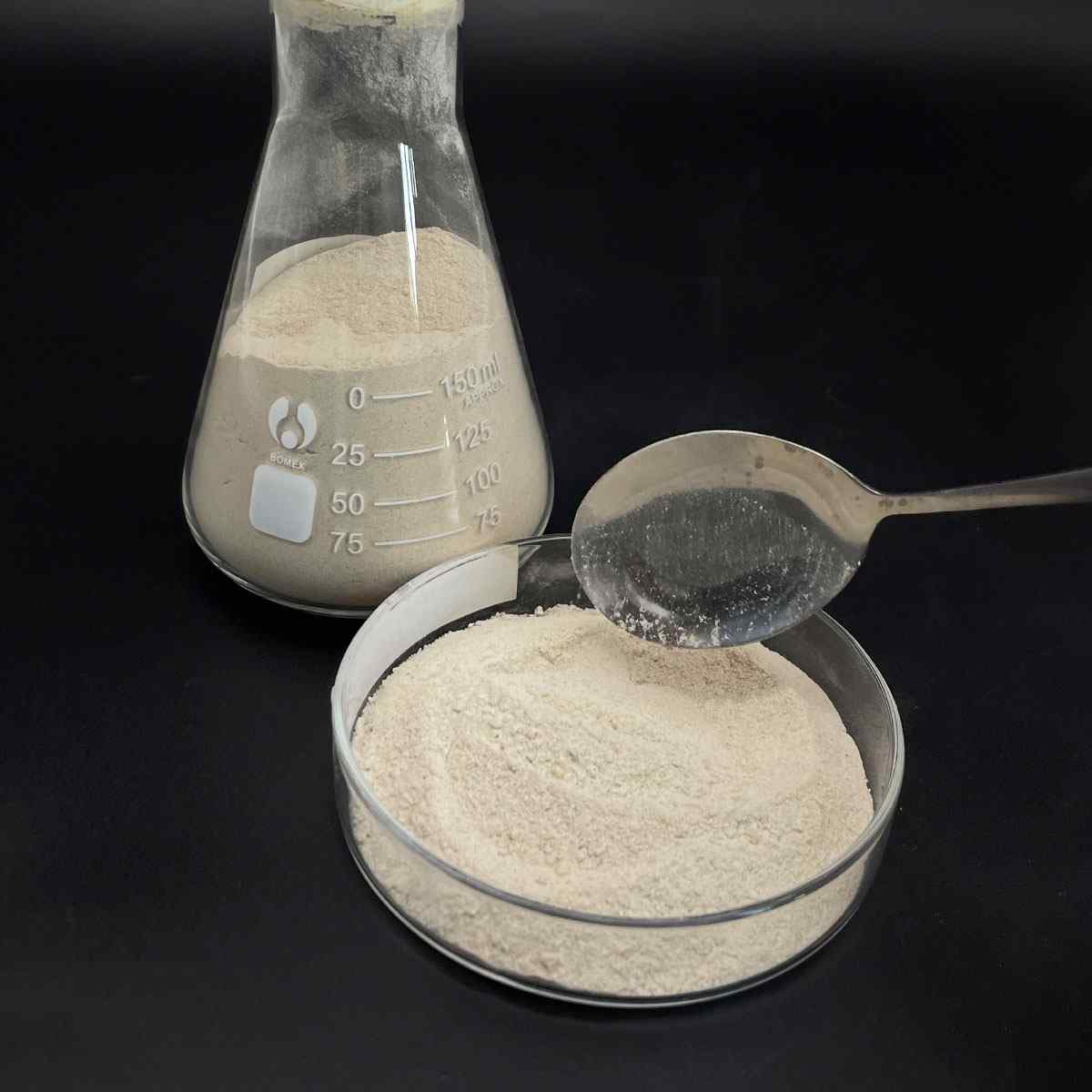

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of high quality pure molybdenum bar rod per kg

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(high quality pure molybdenum bar rod per kg)

Parameters of high quality pure molybdenum bar rod per kg

Molybdenum, a chemical element with the symbol Mo and atomic number 42, is a hard, corrosion-resistant metal that boasts exceptional strength and heat resistance. It is an essential component in various high-tech industries due to its unique properties, such as high melting point, low thermal expansion coefficient, and excellent wear resistance. Molybdenum bars and rods are widely used in applications where durability and performance under extreme conditions are paramount.

When it comes to high-quality pure molybdenum bars and rods, several parameters are crucial to ensure their suitability for specific uses. These parameters include:

1. Purity: The purity level of molybdenum is typically measured in weight percentage of Mo, with grades ranging from 99.5% to 99.99%. A purity of 99.99% indicates a near-ideal composition, minimizing impurities that could affect performance or introduce unwanted side effects.

2. Grain Structure: A fine-grained structure is desirable for molybdenum bars, as it enhances mechanical properties like strength and toughness. This can be achieved through controlled processing techniques, such as cold working or annealing.

3. Tensile Strength: High-quality molybdenum rods exhibit excellent tensile strength, which refers to the material’s ability to withstand stress without deforming permanently. This parameter is typically measured in MPa (megapascals) and is a critical factor for applications requiring structural integrity.

4. Yield Strength: The yield strength is the minimum stress at which a material begins to deform plastically. A higher yield strength indicates greater resistance to deformation before failure, making it suitable for load-bearing applications.

5. Hardness: Vickers or Brinell hardness measurements provide insight into the material’s resistance to scratching. A balance between hardness and ductility is important, as too much hardness can lead to brittleness.

6. Thermal Conductivity: Molybdenum is known for its high thermal conductivity, which is vital in applications where efficient heat transfer is required, such as heat sinks, heat exchangers, or thermocouples.

7. Oxidation Resistance: Molybdenum forms a protective oxide layer when exposed to air, which helps prevent corrosion. The quality of this layer can impact the material’s overall performance and service life.

8. Machinability: The ease with which molybdenum can be machined is another important factor. High-quality molybdenum bars should have good formability and minimal tool wear during cutting operations.

9. Surface Finish: The surface finish of the molybdenum rod or bar is often critical for aesthetics and functional requirements, such as reducing friction or ensuring a smooth mating surface.

10. Dimensional Stability: Precise dimensions and dimensional stability are crucial for maintaining consistent performance and preventing dimensional changes under varying temperatures.

In conclusion, high-quality pure molybdenum bars and rods are characterized by their exceptional purity, fine grain structure, and a range of mechanical properties that make them ideal for demanding applications. Manufacturers must adhere to strict specifications and quality control measures to ensure these materials meet the stringent requirements of industries such as aerospace, nuclear power, and chemical processing. By considering these parameters, engineers and buyers can select the most suitable molybdenum products for their projects, optimizing performance and reliability.

(high quality pure molybdenum bar rod per kg)

FAQs of high quality pure molybdenum bar rod per kg

Inquiry us