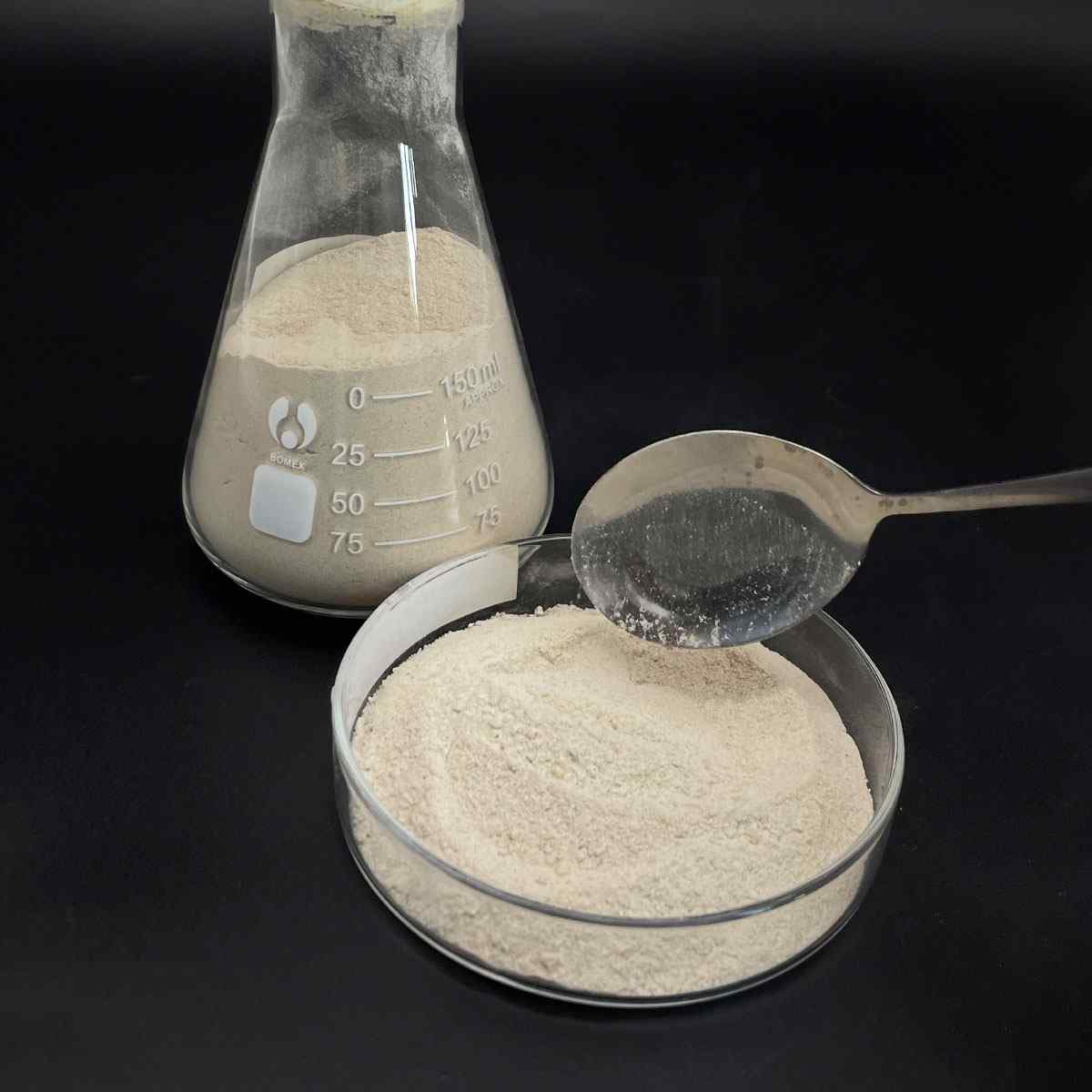

Overview of High Quality And High-Purity Metal Nano Molybdenum Powder Spherical Molybdenum Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High Quality And High-Purity Metal Nano Molybdenum Powder Spherical Molybdenum Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High Quality And High-Purity Metal Nano Molybdenum Powder Spherical Molybdenum Powder)

Parameters of High Quality And High-Purity Metal Nano Molybdenum Powder Spherical Molybdenum Powder

Molybdenum nano powder, a high-quality and high-purity material, is a versatile nanoscale component that has gained significant attention in various industries due to its exceptional properties. This unique form of molybdenum, with a spherical morphology, offers improved performance and functionality compared to its conventional counterparts.

The primary characteristic of this nano molybdenum powder is its particle size, which is typically measured in nanometers, ranging from 50 to 200 nm. The small size allows for an increased surface area-to-volume ratio, resulting in enhanced reactivity and mechanical strength. This feature makes it particularly useful in applications requiring enhanced catalytic activity, wear resistance, or thermal conductivity.

The purity of the spherical molybdenum powder is of utmost importance, often exceeding 99.9% Mo, ensuring minimal impurities that could affect performance. This purity ensures the material’s integrity and reliability in demanding applications where contamination must be avoided.

The spherical shape of the particles contributes to their uniform distribution and ease of dispersion within various matrices. This uniformity leads to more consistent performance and improved bonding strength when incorporated into composite materials. The spherical morphology also reduces agglomeration, a common issue with other nano powders, which can hinder the desired properties.

In terms of manufacturing, the nano molybdenum powder is produced through advanced techniques such as gas atomization, laser ablation, or chemical vapor deposition. These processes ensure the formation of highly pure, monodispersed particles, further enhancing the material’s quality.

The high-quality spherical molybdenum powder finds applications in various sectors, including aerospace, automotive, electronics, and energy production. In aerospace, it is used in high-temperature coatings to improve engine efficiency and durability. In the automotive industry, it is employed for lightweight components, enhancing fuel economy and reducing emissions. Electronics utilize it for advanced conductive pastes and interconnects due to its excellent electrical conductivity and thermal stability.

In the field of energy, molybdenum nano powder serves as a catalyst in fuel cells and solar cells, contributing to enhanced efficiency and longer lifetimes. Additionally, it is used in batteries, where its high surface area enhances electrochemical reactions and improves overall performance.

In summary, high-quality and high-purity spherical molybdenum nano powder stands out due to its exceptional properties, such as its fine particle size, spherical morphology, and superior purity. These attributes make it a sought-after material in various industries, where it delivers enhanced performance, improved efficiency, and robustness in demanding applications. As technology continues to advance, the potential for this nano material to revolutionize various sectors only grows.

(High Quality And High-Purity Metal Nano Molybdenum Powder Spherical Molybdenum Powder)

FAQs of High Quality And High-Purity Metal Nano Molybdenum Powder Spherical Molybdenum Powder

Inquiry us