Overview of High Quality And High-Purity Metal Nano Molybdenum Powder Spherical Molybdenum Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High Quality And High-Purity Metal Nano Molybdenum Powder Spherical Molybdenum Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

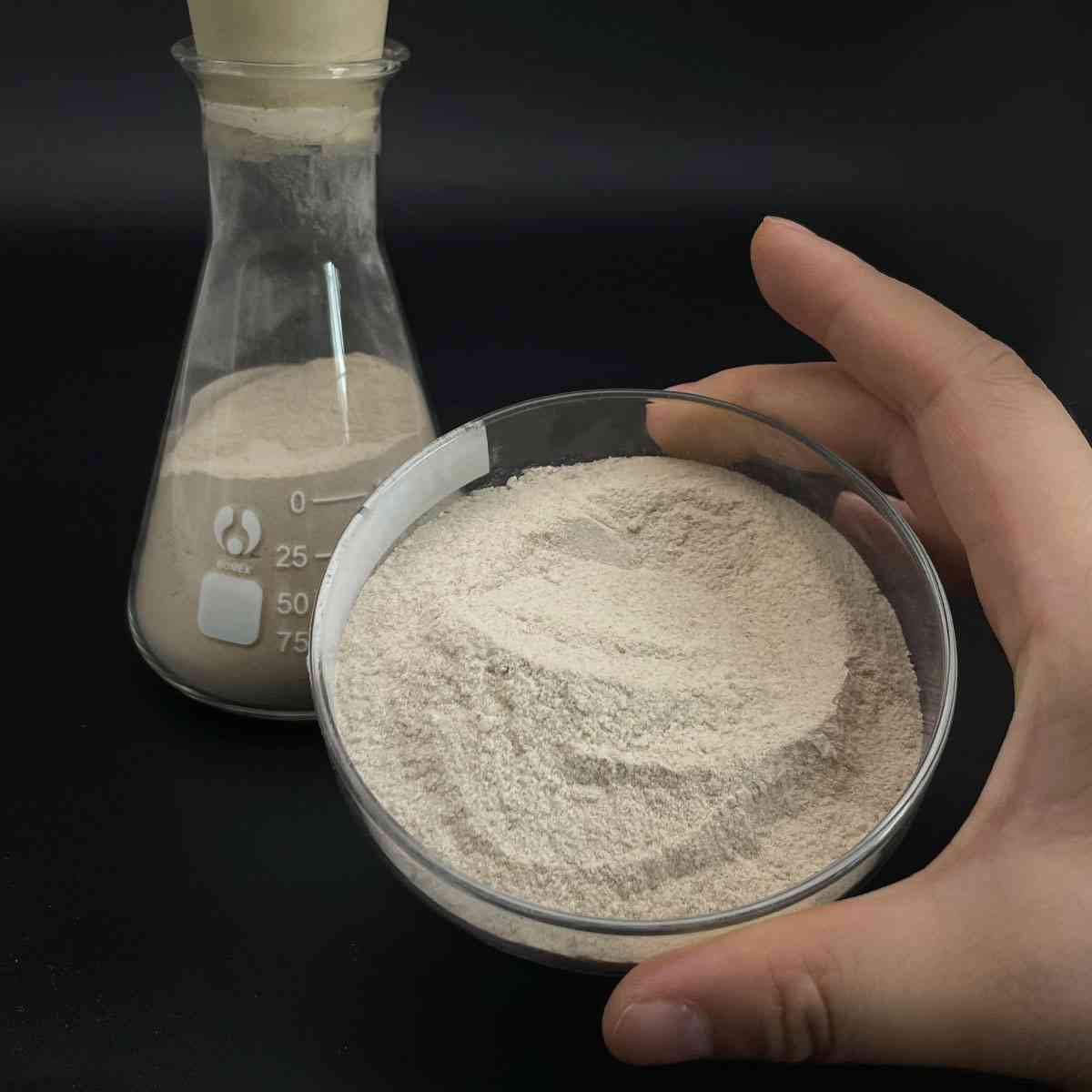

(High Quality And High-Purity Metal Nano Molybdenum Powder Spherical Molybdenum Powder)

Parameters of High Quality And High-Purity Metal Nano Molybdenum Powder Spherical Molybdenum Powder

Molybdenum nano powder, a high-quality and high-purity material, is an advanced form of the element molybdenum that has revolutionized various industries due to its unique properties. This nano-sized powder consists of spherical particles with exceptional characteristics that set it apart from conventional molybdenum forms.

The starting point for this nano-molybdenum is typically extracted from molybdenite, a naturally occurring mineral rich in molybdenum. Through a series of sophisticated processes, including, purification, and reduction, the metal is transformed into submicron or even nanometer-sized particles. The purity level often exceeds 99.9%, ensuring a minimal presence of impurities that could affect performance.

One of the key features of spherical molybdenum powder is its uniform particle shape, which leads to better dispersion and improved surface area. This increased surface-to-volume ratio enhances reactivity and facilitates quicker chemical reactions in various applications. The spherical morphology also contributes to better mechanical stability and resistance to agglomeration during handling.

The high purity and homogeneity of the nano-molybdenum powder guarantee consistent performance across different industries. In the aerospace sector, it finds application as a coating material, improving wear resistance and thermal stability in engine components. In electronics, it acts as a conductive paste in printed circuit boards, contributing to enhanced conductivity and reliability.

In the field of lubrication, nano-molybdenum serves as a high-performance additive, enhancing oil’s viscosity index and reducing friction, thus prolonging equipment life. It is also utilized in composite materials, where its nanoscale structure improves strength and toughness.

In the medical field, molybdenum nano powder is being researched for potential use in targeted drug delivery systems and as a catalyst for bio-imaging. Its biocompatibility and antibacterial properties make it an intriguing material for developing novel medical devices.

Environmental applications include water treatment, where molybdenum-based catalysts aid in removing contaminants more efficiently. Additionally, it finds use in battery technologies, particularly in lithium-ion batteries, where its high surface area improves charge transfer rates.

In summary, high-quality and high-purity spherical molybdenum nano powder is a versatile material characterized by its exceptional properties such as uniform particle size, high purity, and enhanced reactivity. Its unique attributes make it indispensable in various sectors, ranging from aerospace to healthcare, where it delivers superior performance and enables innovative solutions. As research and technology continue to advance, the potential applications for this nano material are expected to expand further.

(High Quality And High-Purity Metal Nano Molybdenum Powder Spherical Molybdenum Powder)

FAQs of High Quality And High-Purity Metal Nano Molybdenum Powder Spherical Molybdenum Powder

Inquiry us