Overview of High Quality 99.95% Niobium Wire in stock Niobium alloy

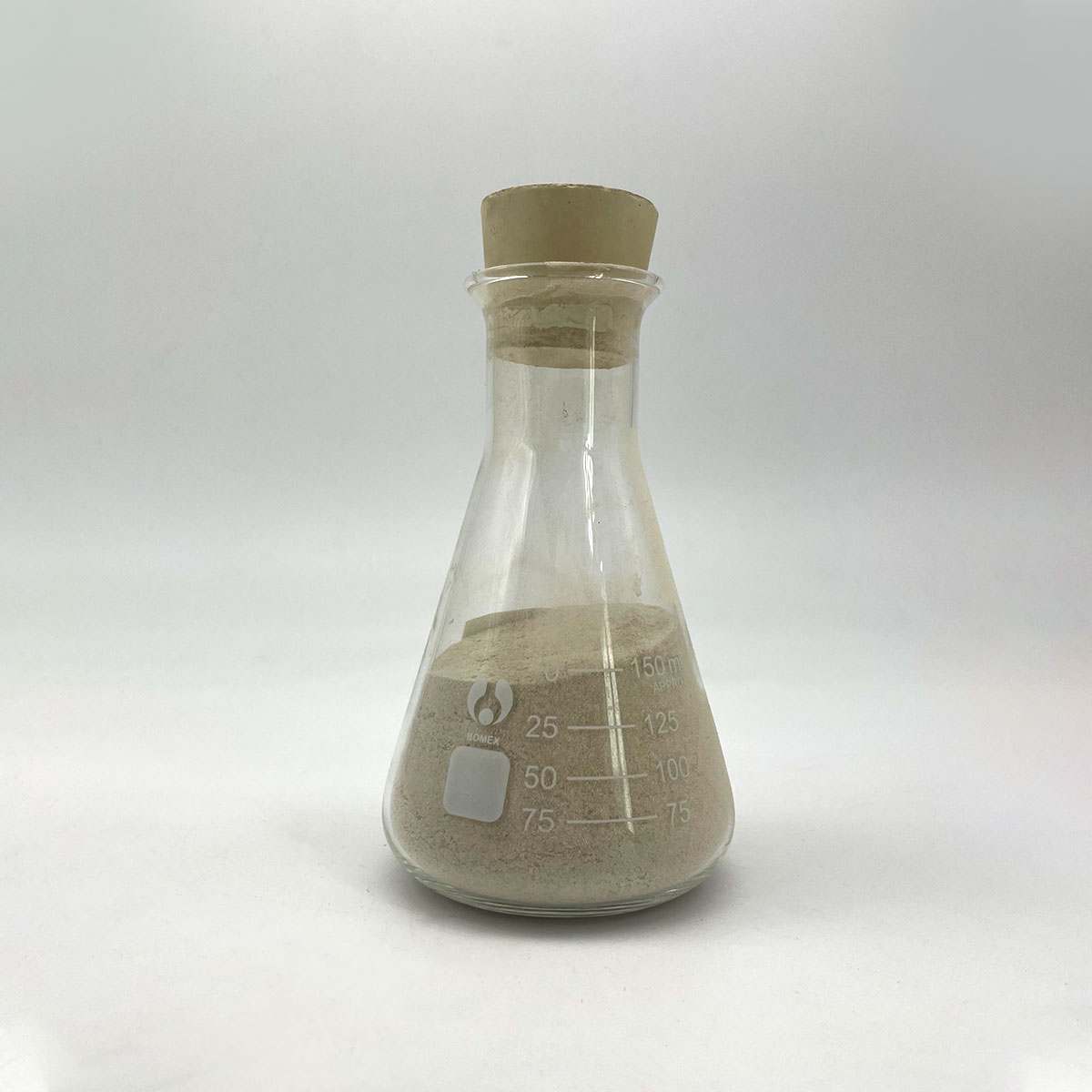

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High Quality 99.95% Niobium Wire in stock Niobium alloy

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High Quality 99.95% Niobium Wire in stock Niobium alloy )

Parameters of High Quality 99.95% Niobium Wire in stock Niobium alloy

Niobium, a chemical element with the symbol Nb and atomic number 41, is a lustrous, grey metallic transition metal that possesses unique properties that make it a valuable material in various scientific and industrial applications. High-quality 99.95% pure niobium wire is a sought-after product due to its exceptional purity, ductility, and superconducting capabilities.

The 99.95% purity level indicates that the wire is virtually free of impurities, which is crucial for applications where high conductivity and performance are paramount. This level of purity ensures minimal degradation of the material’s properties and enables it to exhibit near-perfect superconductivity, a phenomenon where electrical resistance drops to zero below a critical temperature. This feature is widely used in cutting-edge technologies like MRI machines, particle accelerators, and quantum computing devices.

Niobium wire is known for its excellent mechanical properties, such as high tensile strength, good formability, and a low coefficient of thermal expansion. These attributes make it suitable for use in aerospace, automotive, and defense industries, where components need to withstand extreme temperatures and mechanical stress. The wire can be easily shaped and formed into intricate geometries without losing structural integrity, making it ideal for applications like lightweight structures, springs, and fasteners.

In addition to its mechanical strength, niobium is a strong absorber of hydrogen, which makes it useful in hydrogen storage systems and fuel cell technologies. Its corrosion resistance is also noteworthy, as it maintains its shine and integrity even in harsh environments, reducing maintenance costs and extending the service life of components.

The manufacturing process for 99.95% niobium wire typically involves refining the niobium ore, followed by purification through techniques like electrolysis or zone refining. The resulting wire is then cold-worked to achieve the desired dimensions and surface finish. It can be drawn into thin wires with diameters ranging from micrometers to millimeters, catering to the specific requirements of various industries.

In summary, high-quality 99.95% niobium wire is a premium material characterized by exceptional purity, mechanical strength, and superconducting properties. Its widespread applications span across numerous sectors, including energy, transportation, and advanced technology, due to its versatility, durability, and ability to perform under demanding conditions. With its continued research and development, niobium remains an essential component in the pursuit of innovation and efficiency in modern engineering and science.

(High Quality 99.95% Niobium Wire in stock Niobium alloy )

FAQs of High Quality 99.95% Niobium Wire in stock Niobium alloy

Inquiry us