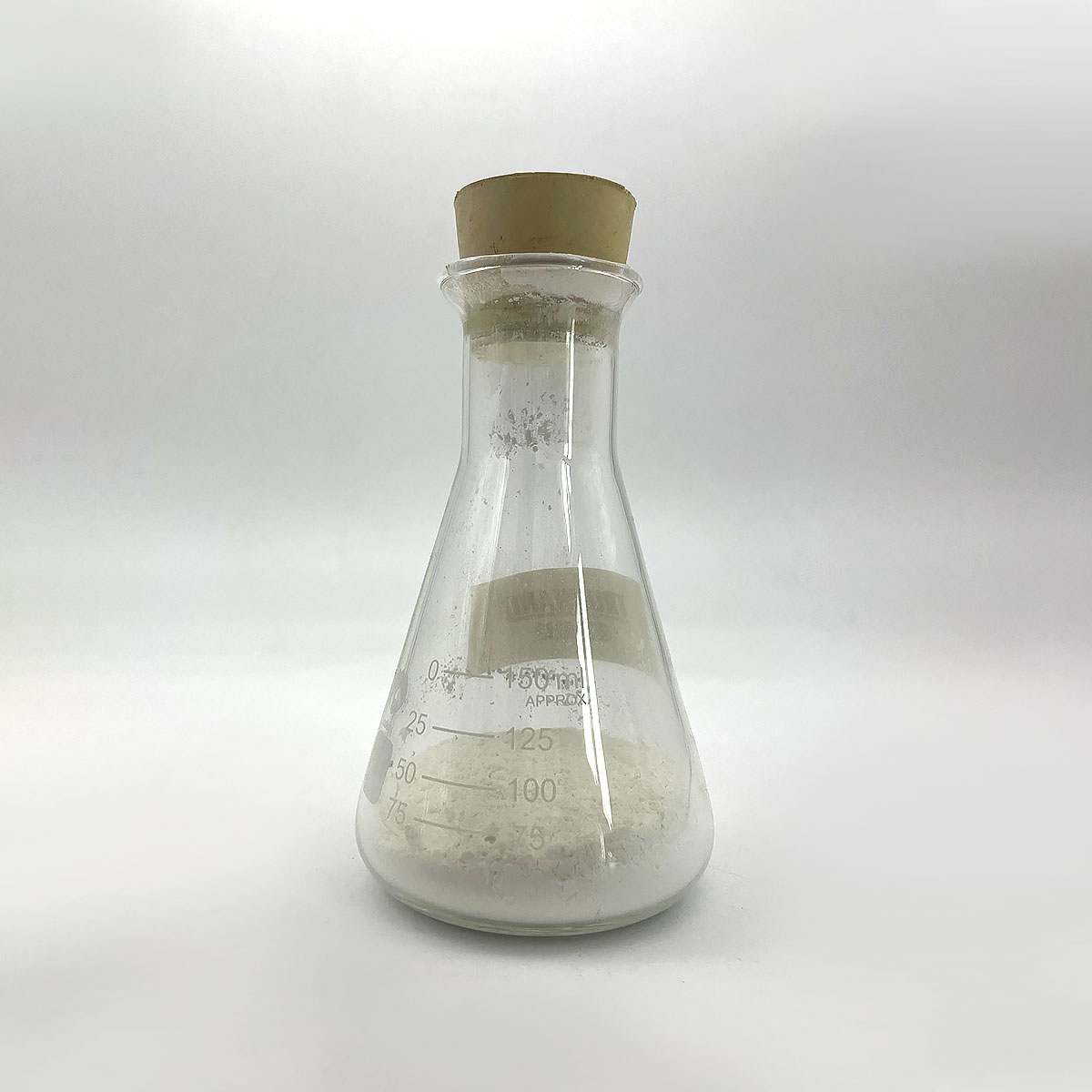

Overview of High-purity Tungsten Powder Tungsten Carbide Powder Ultra-fine Tungsten Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High-purity Tungsten Powder Tungsten Carbide Powder Ultra-fine Tungsten Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High-purity Tungsten Powder Tungsten Carbide Powder Ultra-fine Tungsten Powder)

Parameters of High-purity Tungsten Powder Tungsten Carbide Powder Ultra-fine Tungsten Powder

Tungsten, a chemical element with the symbol W and atomic number 74, is a rare and incredibly dense metal known for its exceptional strength, heat resistance, and high melting point. It is often referred to as the “white gold” due to its lustrous white appearance. Tungsten powders, specifically high-purity tungsten powder, tungsten carbide powder, and ultra-fine tungsten powder, are versatile materials that find applications across various industries due to their unique properties.

1. High-Purity Tungsten Powder: This type of powder consists of tungsten particles with a purity level typically above 99.9%. The purity ensures minimal impurities, which results in improved performance and reliability. It is widely used in electronics, where it is employed in filaments, electrodes, and as a conductive material in semiconductor manufacturing. High-purity tungsten powders also have applications in aerospace, where they are used in jet engine components that withstand extreme temperatures.

2. Tungsten Carbide Powder: A composite material formed by combining tungsten with carbon, tungsten carbide powder is known for its extraordinary hardness and wear resistance. This powder is synthesized through a process that fuses tungsten and carbon particles at high temperatures, creating a rigid and durable compound. Tungsten carbide is prevalent in cutting tools, wear-resistant coatings, and even dental implants due to its ability to maintain edge sharpness and resist abrasive wear.

3. Ultra-Fine Tungsten Powder: Ultra-fine tungsten powder refers to particles with diameters in the nanometer range, typically less than 100 nm. These powders possess an increased surface area, which enhances reactivity and allows for better bonding in composite materials. They are utilized in advanced applications like thermal spray coatings, where fine particles improve thermal conductivity and wear resistance. Additionally, ultra-fine tungsten powder finds applications in the field of electronics, specifically in the fabrication of conductive pastes and thin films.

In summary, tungsten powders, whether high-purity, tungsten carbide, or ultra-fine, offer exceptional properties that make them indispensable in modern technology. Their strength, heat resistance, and unique combinations with other elements enable their use in industries ranging from aerospace to automotive, electronics, and manufacturing. The ongoing development of new techniques for processing these powders ensures that their potential applications continue to expand in the future.

(High-purity Tungsten Powder Tungsten Carbide Powder Ultra-fine Tungsten Powder)

FAQs of High-purity Tungsten Powder Tungsten Carbide Powder Ultra-fine Tungsten Powder

Inquiry us