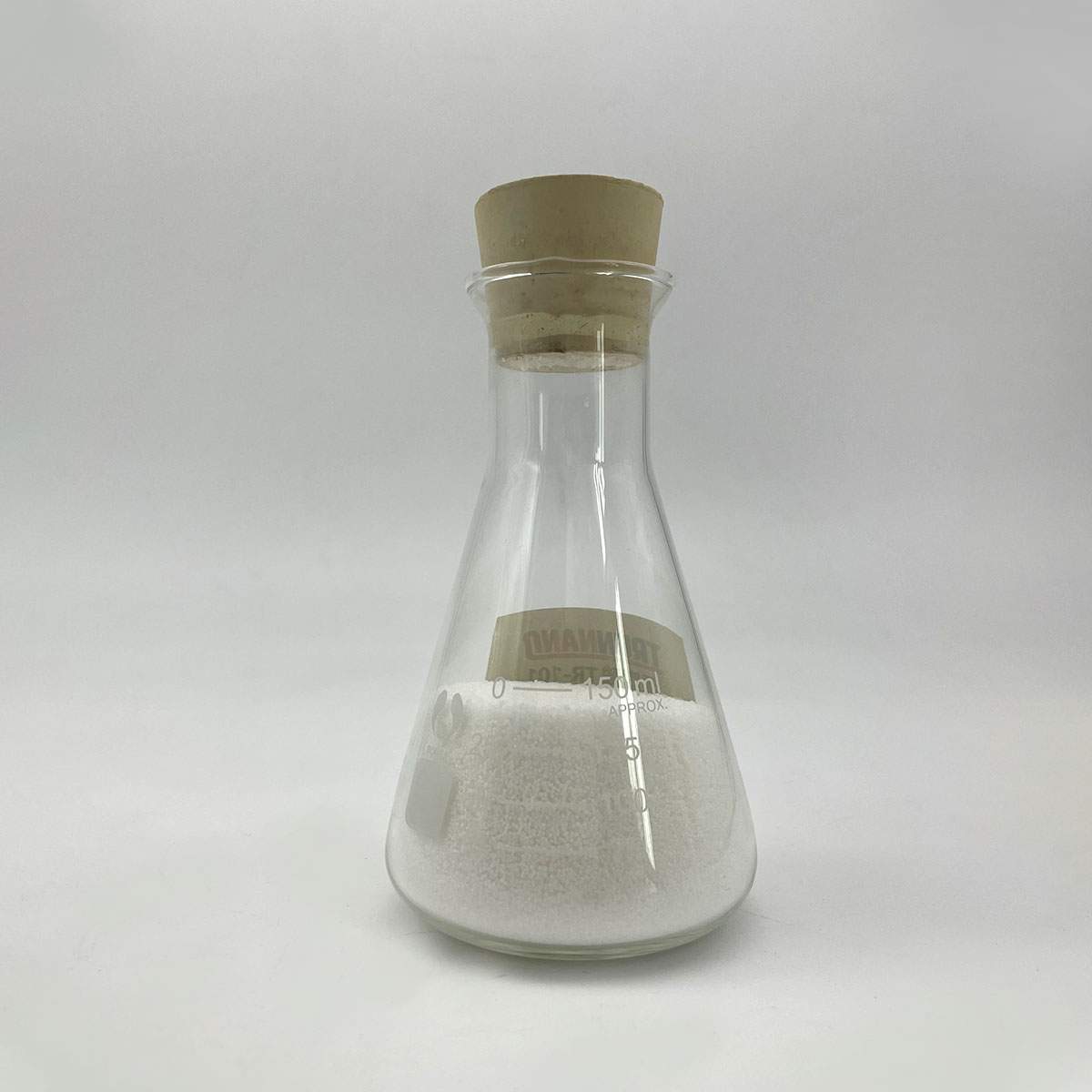

Overview of High purity tantalum ring Tantalum powder pure tantalum per kg for 3D printing

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High purity tantalum ring Tantalum powder pure tantalum per kg for 3D printing

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High purity tantalum ring Tantalum powder pure tantalum per kg for 3D printing)

Parameters of High purity tantalum ring Tantalum powder pure tantalum per kg for 3D printing

Title: High Purity Tantalum Ring and Powder for 3D Printing: A Comprehensive Overview

Introduction

Tantalum, a rare and valuable transition metal, has gained significant attention in the realm of 3D printing due to its unique combination of properties. This advanced material, known for its exceptional strength, corrosion resistance, and high melting point, is now available in the form of a pure tantalum ring and fine powder, tailored specifically for 3D printing applications. In this article, we delve into the key parameters of these tantalum products and their potential benefits for intricate designs.

1. Product Description

The high purity tantalum ring is a precision-engineered component made from pure tantalum, ensuring a minimum impurity level for optimal performance. It is designed to withstand harsh environments and maintain structural integrity under extreme conditions. The ring’s smooth surface and precise dimensions make it suitable for use as a support structure or as part of a functional component in 3D printed assemblies.

On the other hand, tantalum powder is an ultrafine, high-purity form of the metal that can be used as the feedstock for direct metal laser sintering (DMLS) or selective laser melting (SLM) processes in 3D printing. This fine powder offers exceptional resolution and accuracy, enabling the creation of intricate geometries and complex parts.

2. Properties for 3D Printing

– Melting Point: Tantalum boasts a melting point of around 3,027°C (5,481°F), which makes it ideal for applications requiring heat resistance and durability. This property ensures that printed parts maintain their integrity even under high temperatures.

– Strength and Hardness: With a high modulus of elasticity and yield strength, tantalum powder results in strong, lightweight components that can withstand mechanical stress.

– Corrosion Resistance: Tantalum’s inherent resistance to acids, alkalis, and even molten salts makes it resistant to degradation, making it suitable for applications where chemical stability is critical.

– Biocompatibility: Tantalum’s non-reactive nature with biological fluids makes it a promising choice for medical implants and aerospace components that come into contact with human tissue.

3. Particle Size and Distribution

For efficient 3D printing, the tantalum powder should have a narrow particle size distribution, typically ranging from 15-53 microns. This ensures consistent layer adhesion and print quality, leading to fewer defects and improved part strength.

4. Processing Parameters

When selecting tantalum powder for 3D printing, it’s crucial to consider the specific process parameters such as laser power, scanning speed, and layer thickness. These factors need to be optimized to achieve the desired surface finish, porosity, and dimensional accuracy.

5. Applications

– Aerospace: Tantalum’s high strength-to-weight ratio and resistance to thermal expansion make it ideal for aerospace components like engine parts, heat exchangers, and structural elements.

– Medical Devices: Its biocompatibility and wear-resistant properties make tantalum suitable for orthopedic implants, dental crowns, and surgical tools.

– Electronics: Tantalum capacitors and electrical contacts benefit from the material’s stability and low self-discharge rate.

Conclusion

In summary, high purity tantalum rings and powder offer unique advantages for 3D printing, particularly in industries demanding durability, corrosion resistance, and exceptional performance. By understanding the key parameters, users can tailor their printing processes to create innovative and reliable components that push the boundaries of conventional manufacturing techniques. As 3D printing technology continues to evolve, tantalum is poised to play a pivotal role in the development of advanced materials solutions.

(High purity tantalum ring Tantalum powder pure tantalum per kg for 3D printing)

FAQs of High purity tantalum ring Tantalum powder pure tantalum per kg for 3D printing

Inquiry us