Overview of high purity tantalum powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of high purity tantalum powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

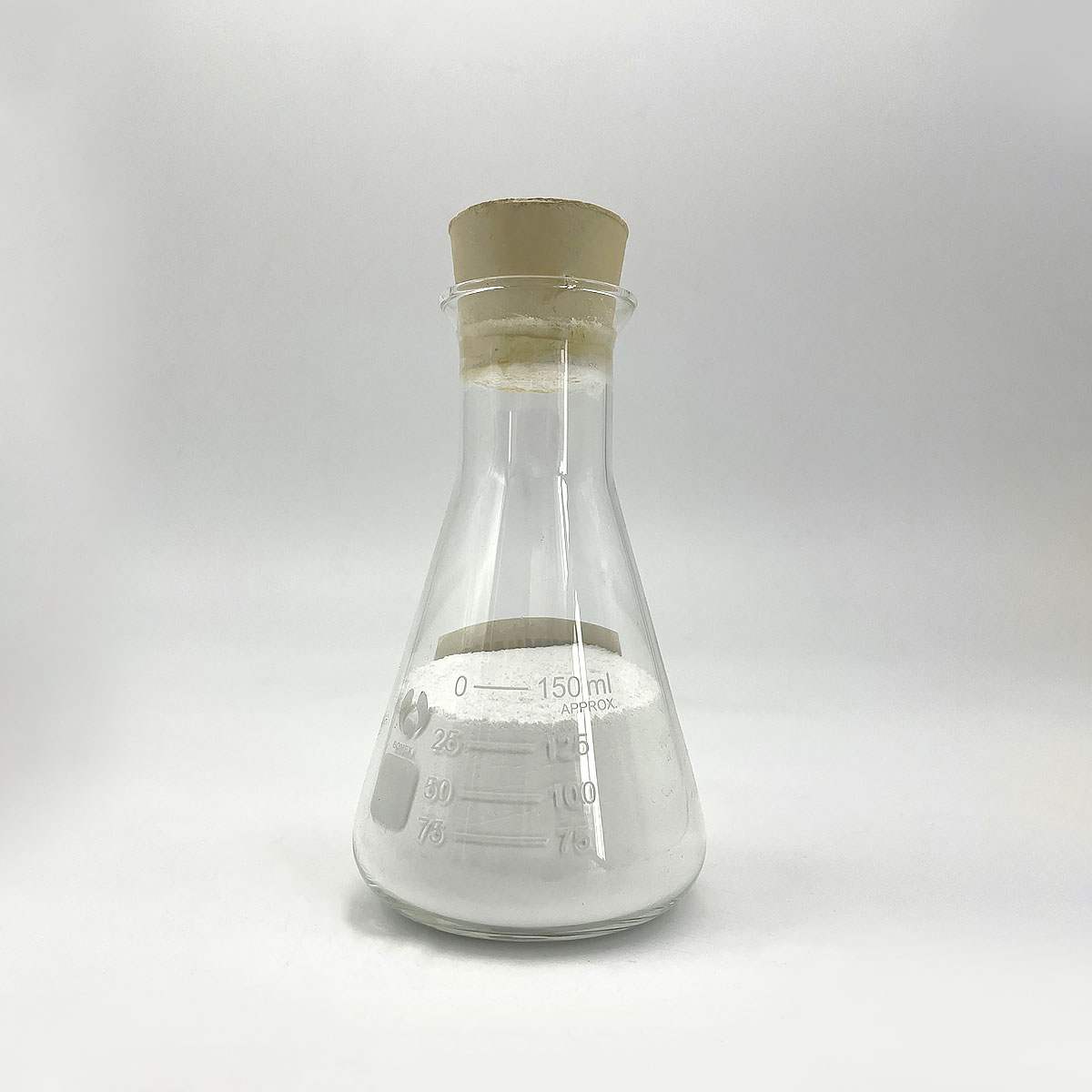

(high purity tantalum powder)

Parameters of high purity tantalum powder

High Purity Tantalum Powder: A Comprehensive Overview

Tantalum, a chemical element with the symbol Ta and atomic number 73, is a rare, lustrous transition metal known for its exceptional strength, corrosion resistance, and heat conductivity. It holds a special place in various industrial applications due to its unique combination of properties, making high purity tantalum powder a sought-after material.

1. Elemental Properties: Tantalum has a silvery-gray appearance and is extremely dense, with a density of approximately 16.65 grams per cubic centimeter. Its melting point is exceptionally high, at around 3,287 degrees Celsius (5,931 degrees Fahrenheit), making it one of the hardest elements to melt. It is also highly malleable and ductile, allowing it to be shaped into thin sheets or wires without breaking.

2. Purity Standards: High purity tantalum powder typically refers to grades with a minimum impurity content of 99.99% (4N, or 4N+), indicating that only a trace amount of impurities are present. This level of purity ensures minimal contamination and superior performance in applications where purity is critical, such as in electronics, aerospace, and medical devices.

3. Chemical Stability: Tantalum’s resistance to acids, alkalis, and most solvents makes it ideal for use in harsh environments. It does not corrode easily, which is particularly important in industries like chemical processing and nuclear power. The oxide layer formed on the surface of tantalum provides an additional barrier against corrosion.

4. Electrical Conductivity: Tantalum has excellent electrical conductivity, making it a popular choice for capacitors, especially in high-frequency circuits and military equipment. The high purity of the powder ensures consistent performance and reliability over time.

5. Thermal Conductivity: Tantalum is an outstanding thermal conductor, which makes it suitable for heat sinks, crucibles, and other components that require efficient heat transfer. High purity tantalum powder enables the creation of components with minimal thermal resistance, enhancing overall system efficiency.

6. Mechanical Strength: Tantalum’s high strength-to-weight ratio makes it suitable for applications where lightweight yet strong materials are required. It can withstand significant stress without deformation, making it ideal for components subjected to heavy loads, such as turbine blades or bearings.

7. Processing Techniques: To produce high purity tantalum powder, a variety of methods are employed, including the reduction of tantalum pentoxide (Ta2O5) with elemental tantalum or carbon at high temperatures. Purification techniques, such as zone refining and electrolysis, are used to achieve the desired level of purity.

8. Applications: Some key areas where high purity tantalum powder finds extensive use include:

– Electronics: As a component in capacitors, tantalum offers low capacitance drift, long-term stability, and high reliability.

– Aerospace: Tantalum alloys are used in engine parts, rocket nozzles, and structural components due to their lightweight and high-temperature resistance.

– Medical Devices: Tantalum implants are biocompatible and resistant to corrosion, making them suitable for orthopedic and dental applications.

– Nuclear Industry: Tantalum is employed in fuel cladding, heat exchangers, and other components due to its radiation resistance and durability.

In conclusion, high purity tantalum powder is a premium material with exceptional properties that make it indispensable in various industries. Its combination of strength, corrosion resistance, and electrical conductivity make it a preferred choice for demanding applications where performance and reliability are paramount. As technology continues to advance, the demand for this versatile metal is expected to grow, driving the need for even higher purity grades in the future.

(high purity tantalum powder)

FAQs of high purity tantalum powder

Inquiry us