Overview of High purity Mo metal 99.95% molybdenum powder for

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

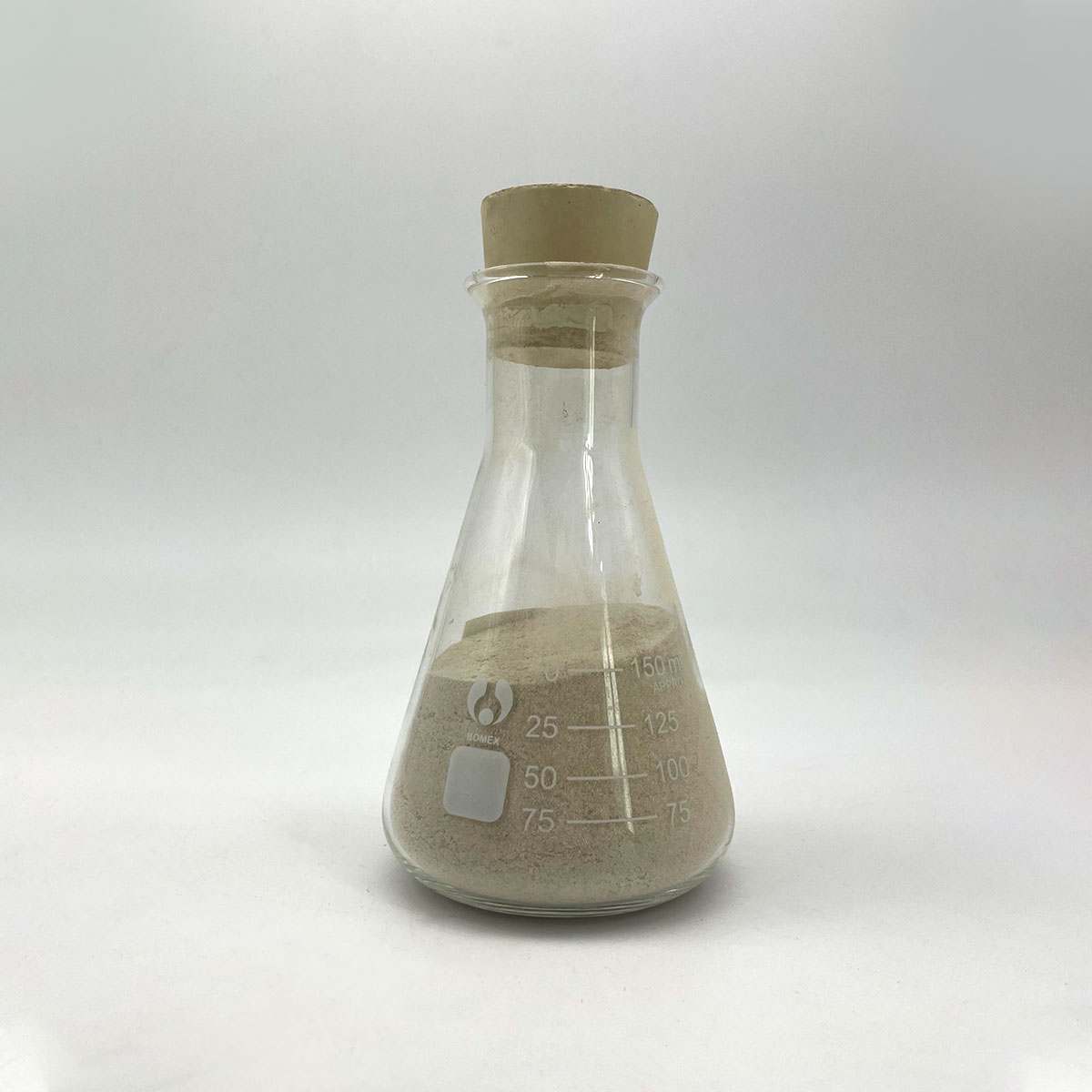

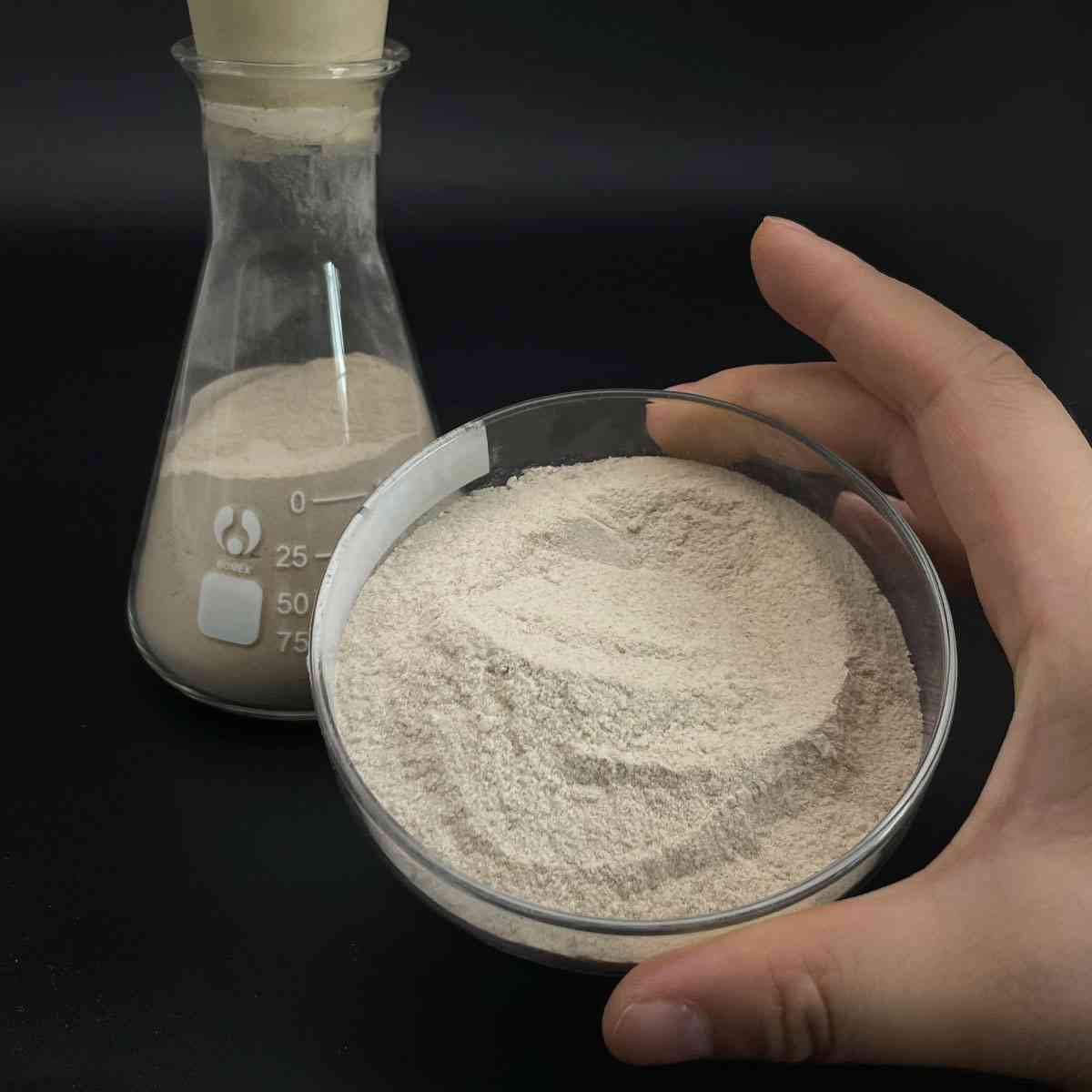

Features of High purity Mo metal 99.95% molybdenum powder for

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High purity Mo metal 99.95% molybdenum powder for )

Parameters of High purity Mo metal 99.95% molybdenum powder for

High Purity Molybdenum (Mo) Metal: A Key Material in Advanced Technologies

Molybdenum, with the chemical symbol Mo, is a silvery-gray transition metal that holds a prominent position in various industrial applications due to its exceptional strength, corrosion resistance, and high-temperature stability. At a purity level of 99.95%, this particular form of molybdenum powder is of utmost importance in ensuring optimal performance across numerous sectors.

In the field of electronics, molybdenum finds its use in the fabrication of high-performance electronic components, such as filaments for light-emitting diodes (LEDs), and as a catalyst in semiconductor manufacturing processes. Its excellent thermal conductivity and electrical resistivity make it an ideal material for heat sinks and microelectronic devices, where precise temperature control is crucial.

In the aerospace industry, molybdenum’s lightweight and strong properties contribute to the development of advanced aircraft structures, engine components, and even rocket engines. The 99.95% pure molybdenum powder is often used in composite materials, enhancing their strength and durability under extreme conditions.

The chemical and petrochemical industries rely on molybdenum for its ability to form stable alloys, particularly in high-temperature applications. These alloys, containing molybdenum, exhibit exceptional resistance to corrosion and wear, making them indispensable in refining equipment, pipelines, and valves.

In the energy sector, molybdenum plays a vital role in the nuclear industry as a material for reactor components, such as fuel cladding and control rods. The high purity of the metal ensures long-term reliability and safety in these critical applications.

Furthermore, molybdenum is employed in the production of lubricants, where it acts as a catalyst, improving the efficiency and durability of oil-based formulations. It is also used in the development of superalloys, which combine molybdenum with other metals to create materials capable of withstand extreme temperatures and pressures, commonly found in jet engines and gas turbines.

In the medical field, molybdenum has shown potential as a dietary supplement, believed to enhance certain biological functions and protect against oxidative stress. High purity molybdenum powder is essential in the production of these supplements to maintain the desired therapeutic effects.

Lastly, molybdenum’s unique properties have led to its use in art and jewelry, where its attractive luster and durability make it a sought-after material for crafting fine pieces.

In conclusion, the 99.95% purity molybdenum powder is a versatile material that holds significant value in various industries due to its remarkable properties. Its exceptional strength, corrosion resistance, and thermal stability make it an indispensable component in cutting-edge technologies, from electronics to aerospace, energy, and medicine. As research continues to uncover new applications, the demand for high purity molybdenum is likely to grow, solidifying its position as a key material in the modern world.

(High purity Mo metal 99.95% molybdenum powder for )

FAQs of High purity Mo metal 99.95% molybdenum powder for

Inquiry us