Overview of High Purity 99%min molybdenum disulfide Mos2 Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High Purity 99%min molybdenum disulfide Mos2 Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

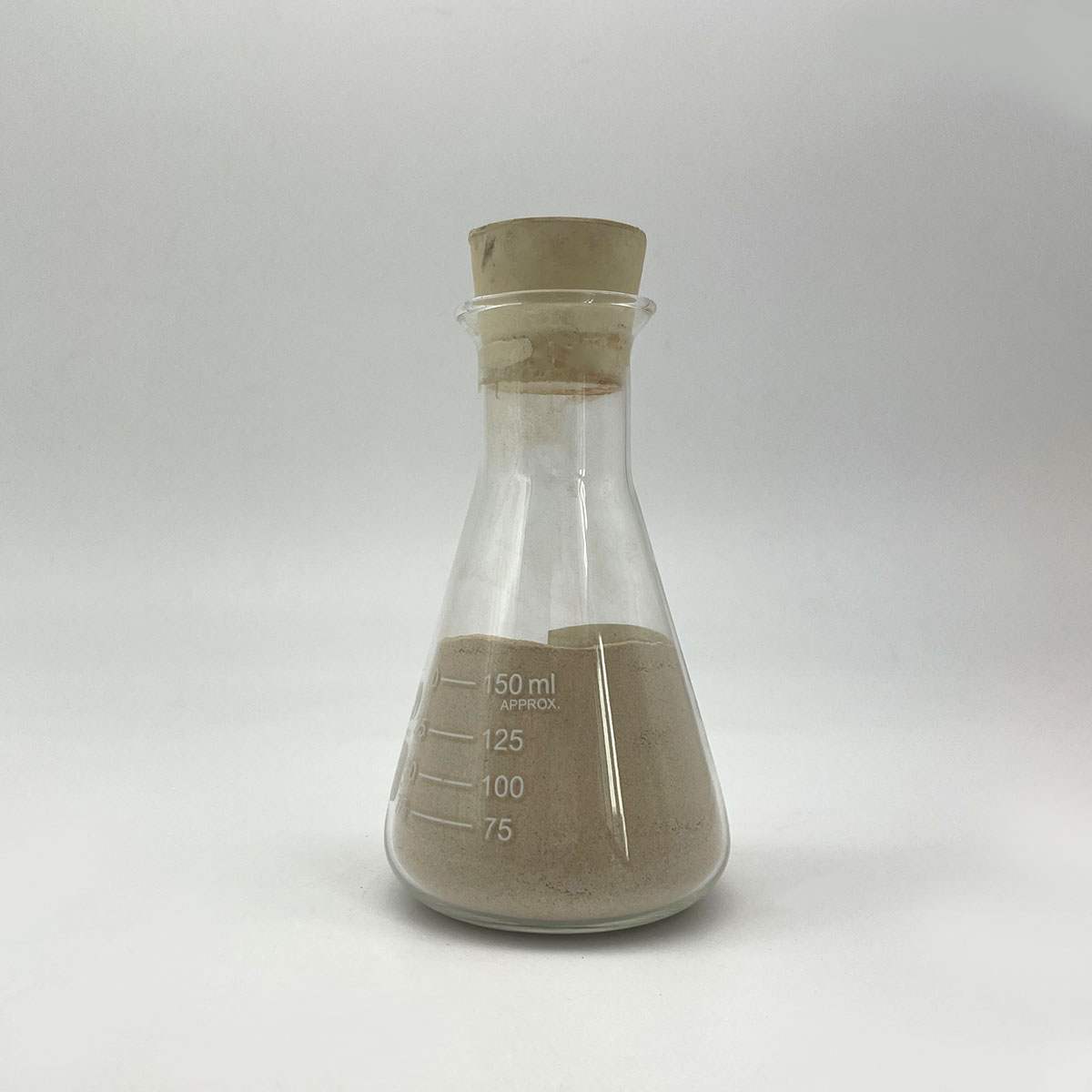

(High Purity 99%min molybdenum disulfide Mos2 Powder)

Parameters of High Purity 99%min molybdenum disulfide Mos2 Powder

Molybdenum disulfide (MoS2), also known as MoS2 powder, is a highly sought-after material due to its exceptional properties and versatile applications across various industries. With a purity level of at least 99% min, it boasts a remarkable combination of chemical stability, thermal conductivity, and electrical conductivity, making it an ideal choice for numerous applications.

The physical appearance of high purity MoS2 powder is characterized by its lamellar or layered structure, giving it a shiny, metallic luster. The particles are typically in the form of micron-sized flakes or submicron-sized crystals, ensuring a large surface area to volume ratio, which is crucial for enhancing its catalytic and electronic properties. The particle size distribution is carefully controlled during the manufacturing process to ensure consistency and optimal performance.

In terms of crystal structure, MoS2 adopts a trigonal prismatic arrangement, with molybdenum atoms sandwiched between layers of sulfur atoms. This hexagonal lattice structure gives rise to its unique mechanical properties, such as high strength and flexibility, making it resistant to deformation under stress. Additionally, the van der Waals forces between the layers contribute to its excellent lubricity and self-lubricating nature.

One of the most notable features of MoS2 is its exceptional thermal conductivity, which makes it an effective heat dissipation material in electronic devices and heat exchangers. Its high melting point (over 2623°C) ensures its durability even under extreme temperatures, making it suitable for high-temperature applications like aerospace and energy industries.

Furthermore, MoS2 is a semiconductor with a direct bandgap, which makes it attractive for optoelectronic applications, such as photodetectors and solar cells. Its ability to absorb light and convert it into electrical current is particularly appealing in thin-film solar cells due to its lightweight and flexible nature.

In the field of lubrication, MoS2 is used as a high-performance lubricant in various industries, including automotive, machinery, and bearings. Its low friction coefficient and resistance to wear make it an ideal choice for reducing energy consumption and extending equipment life.

Another area where MoS2 demonstrates its prowess is in catalysis. As a catalyst support material, it enhances the activity and selectivity of catalysts in chemical reactions, particularly in hydrodesulfurization, hydrogenation, and Fischer-Tropsch synthesis.

In summary, high purity 99% MoS2 powder is a technologically advanced material with a myriad of applications due to its exceptional properties. Its layered structure, thermal and electrical conductivity, and chemical stability make it an essential component in industries ranging from electronics to energy, lubrication, and catalysis. The continuous advancements in synthesis techniques are expected to unlock even more potential for this versatile material in the future.

(High Purity 99%min molybdenum disulfide Mos2 Powder)

FAQs of High Purity 99%min molybdenum disulfide Mos2 Powder

Inquiry us