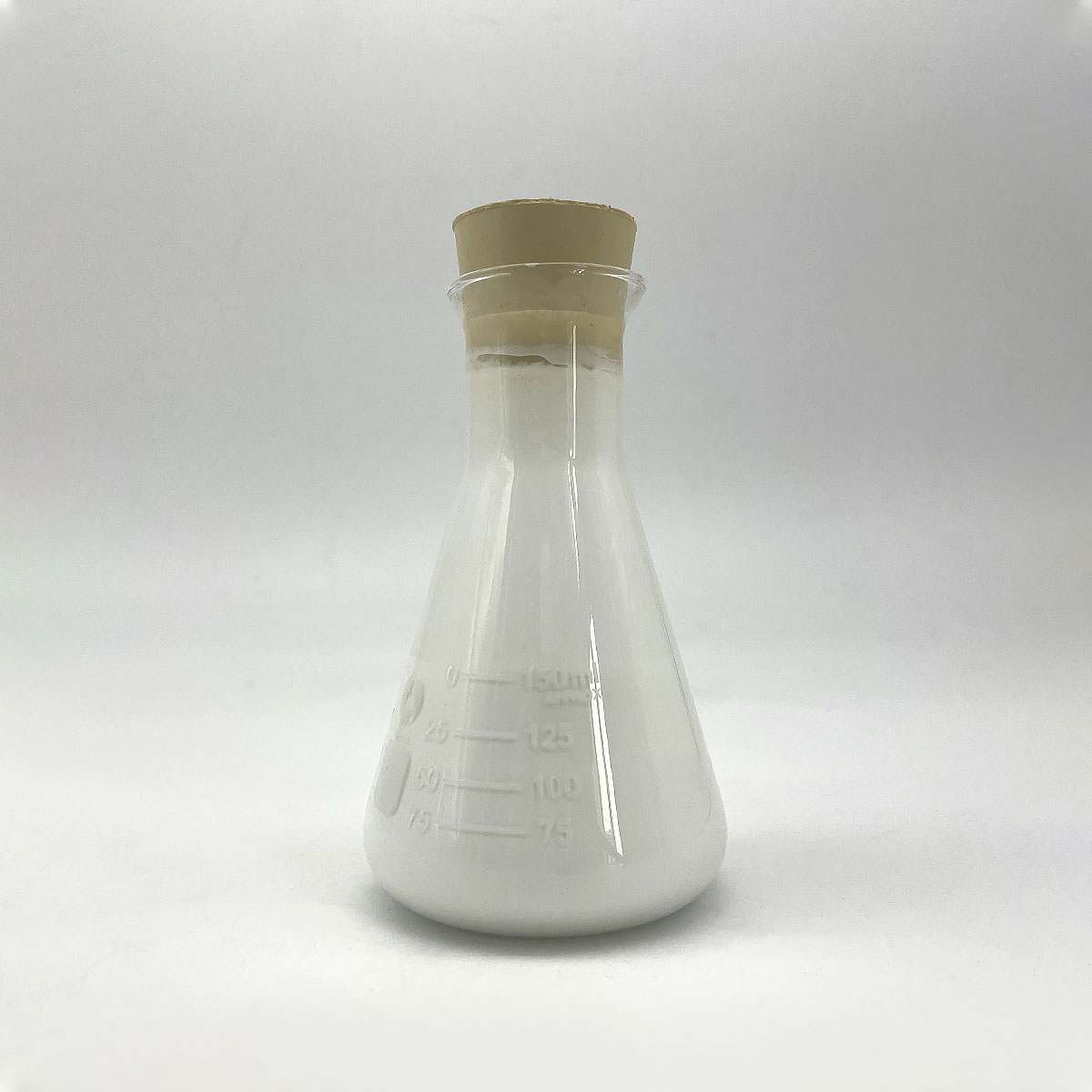

Overview of High Purity 98.5% Molybdenum Disulfide Grease Application MoS2 Powder Molybdenum Disulfide

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of High Purity 98.5% Molybdenum Disulfide Grease Application MoS2 Powder Molybdenum Disulfide

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(High Purity 98.5% Molybdenum Disulfide Grease Application MoS2 Powder Molybdenum Disulfide)

Parameters of High Purity 98.5% Molybdenum Disulfide Grease Application MoS2 Powder Molybdenum Disulfide

Molybdenum disulfide (MoS2), also known as molygraphite or MoS, is a naturally occurring compound with the chemical formula MoS2. It is an essential material due to its exceptional properties that make it highly sought after in various industries. High purity 98.5% MoS2 grease is a premium grade product that boasts outstanding performance characteristics.

The application of this MoS2 powder is versatile and wide-ranging. One of its primary uses is as a lubricant, particularly in high-temperature and high-stress environments. Its low friction coefficient ensures smooth operation, reducing wear and tear on machinery, bearings, and other moving parts. It is commonly used in automotive, aerospace, and manufacturing sectors where extreme conditions can lead to accelerated wear, such as in engines, turbines, and electrical contacts.

Another significant application lies in the field of semiconductor technology. MoS2 acts as an excellent dielectric material, providing a thin, protective layer for electronic components, improving their efficiency and longevity. This makes it a crucial component in the fabrication of microchips and solar cells.

In the lubrication industry, MoS2 grease is often combined with other additives to enhance its anti-wear, anti-corrosive, and heat resistance capabilities. It is resistant to both water and chemicals, making it suitable for use in harsh environments like marine applications, oil and gas exploration, and chemical processing plants.

Moreover, MoS2 is employed in the production of specialized coatings for various surfaces. These coatings not only protect against corrosion but also improve the surface’s tribological properties, extending the life of components in demanding industries like automotive, construction, and metalworking.

As a component in composite materials, MoS2 adds strength, stiffness, and thermal stability to polymer matrices, enhancing the overall performance of these materials in applications like sporting equipment, automotive parts, and even space exploration.

In the field of energy storage, MoS2 is being researched for use in lithium-ion batteries as a cathode material. Its large surface area and conductivity make it a promising candidate for high-capacity and long-life battery technologies.

Lastly, MoS2 finds applications in the pharmaceutical industry, where it is sometimes used as a coating agent for medical implants to reduce friction and promote biocompatibility.

In summary, high purity 98.5% molybdenum disulfide grease is a premium material with extraordinary properties that cater to a multitude of industries. Its unique combination of lubrication, electrical insulation, and surface treatment capabilities make it an indispensable component in modern technology and manufacturing processes. As research and development continue, the potential applications of MoS2 are expected to expand even further, solidifying its position as a key player in the world of advanced materials.

(High Purity 98.5% Molybdenum Disulfide Grease Application MoS2 Powder Molybdenum Disulfide)

FAQs of High Purity 98.5% Molybdenum Disulfide Grease Application MoS2 Powder Molybdenum Disulfide

Inquiry us