Overview of Gripper insert of powder tungsten steel alloy

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Gripper insert of powder tungsten steel alloy

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Gripper insert of powder tungsten steel alloy)

Parameters of Gripper insert of powder tungsten steel alloy

A gripper insert made of powder tungsten steel alloy is a specialized component designed to provide exceptional strength, durability, and wear resistance in high-stress applications. These inserts are often utilized in machinery, robotics, and manufacturing processes where precision gripping and handling of materials are critical.

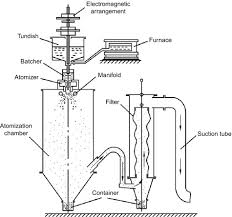

The primary material, tungsten carbide (WC), is a composite material that consists of fine tungsten particles embedded within a cobalt binder. The powder metallurgy process used to create this alloy involves the compression and sintering of tungsten and cobalt powders under high temperatures, resulting in a dense, homogeneous structure with superior mechanical properties.

The key parameters of a typical powder tungsten steel alloy gripper insert include:

1. Composition: The core material is usually a WC:Co ratio of around 90:10, with some manufacturers also incorporating cobalt carbide (Co3C) or niobium carbide (NbC) for enhanced wear resistance and thermal stability.

2. Hardness: A hardness of Vickers (HV) 850-950 or Rockwell C (RC) 68-72 is common, which ensures the insert can withstand heavy loads and abrasive environments without degrading quickly.

3. Tensile strength: The alloy typically has a tensile strength of around 1,400-1,700 MPa, making it extremely strong and capable of withstanding high levels of stress during gripping operations.

4. Wear resistance: Due to its hard and wear-resistant nature, tungsten carbide can maintain its grip and shape even when subjected to prolonged contact with abrasive materials, minimizing the need for frequent replacement.

5. Dimensional accuracy: The gripper insert is precision-engineered to fit snugly into its designated application, ensuring accurate and efficient gripping without excessive wear on the mating surfaces.

6. Heat resistance: Tungsten carbide has good thermal stability, allowing it to operate effectively in temperature ranges up to 600°C without significant loss of performance.

7. Coating options: Some gripper inserts may be coated with a thin layer of PVD (Physical Vapor Deposition) or DLC (Diamond-Like Carbon) for improved lubricity, corrosion resistance, or additional wear protection.

8. Surface finish: The surfaceness is crucial for grip and wear characteristics. A smooth finish with Ra values ranging from 0.1 to 0.5 microns ensures a secure hold on various materials.

9. Life expectancy: With proper maintenance and usage, a well-designed powder tungsten steel alloy gripper insert can last for thousands of cycles, reducing downtime and operating costs.

In conclusion, a gripper insert made of powder tungsten steel alloy is an essential component in industries such as automotive, aerospace, and electronics due to its exceptional properties. Its combination of hardness, strength, wear resistance, and heat tolerance makes it an ideal choice for demanding gripping applications where reliability and longevity are paramount. By understanding and specifying the right parameters, engineers can optimize the performance and efficiency of their equipment.

(Gripper insert of powder tungsten steel alloy)

FAQs of Gripper insert of powder tungsten steel alloy

Inquiry us