Overview of Ferromolybdenum Ferro Molybdenum Powder FeMo Powder 60%

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Ferromolybdenum Ferro Molybdenum Powder FeMo Powder 60%

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

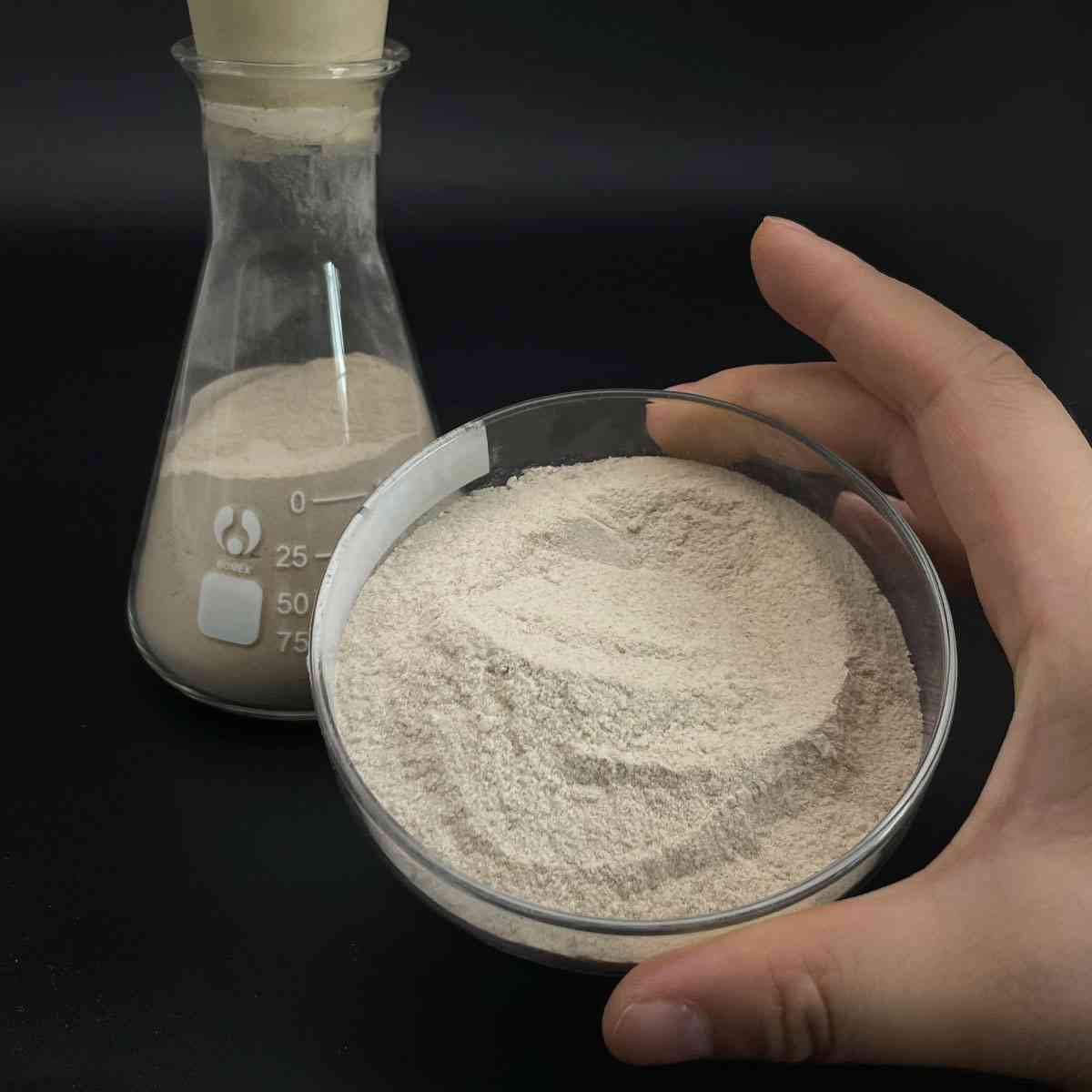

(Ferromolybdenum Ferro Molybdenum Powder FeMo Powder 60%)

Parameters of Ferromolybdenum Ferro Molybdenum Powder FeMo Powder 60%

Ferromolybdenum, also known as Ferro Mo or FeMo powder, is a high-performance metallic compound that combines iron (Fe) and molybdenum (Mo) elements. This powdery material finds extensive applications in various industries due to its unique properties, which make it a sought-after additive for enhancing the strength, durability, and wear resistance of materials.

The primary component, iron, is a versatile element with an atomic number 26, and it constitutes about 60% of the ferromolybdenum mixture. Iron is known for its excellent structural integrity, thermal conductivity, and magnetic properties. It is the most abundant element on Earth and plays a crucial role in steel production, where it acts as a hardening agent, increasing the tensile strength and hardness of the alloy.

Molybdenum, on the other hand, is a transition metal with the atomic number 42. It contributes the remaining 40% to the FeMo powder formula. Molybdenum is renowned for its exceptional resistance to high temperatures, corrosion, and wear. It enhances the material’s ability to maintain its mechanical properties under extreme conditions, making it ideal for use in aerospace, automotive, and chemical industries where components are subjected to harsh environments.

Ferromolybdenum powder is produced through a refining process that involves melting the iron and molybdenum ores, followed by refining, alloying, and grinding to achieve the desired particle size. The resulting powder has a fine, uniform structure, which allows for better dispersion and bonding when incorporated into various materials. Its high surface area ensures efficient interaction with the matrix during sintering or melting, leading to improved properties in the final product.

This compound imparts several benefits to the materials it is added to. It increases hardness and wear resistance, which is particularly useful in applications like bearings, gears, and cutting tools. Additionally, it enhances creep resistance, allowing components to maintain their shape under prolonged exposure to high temperatures without deforming. Ferromolybdenum also improves high-temperature stability, making it suitable for use in exhaust valves, engine parts, and heat exchangers.

In the field of electronics, FeMo powder can be used as a conductor or semiconductor material due to its good electrical conductivity and temperature stability. It finds applications in the production of high-frequency devices and microelectronics. Furthermore, it can be employed in the development of catalysts, where molybdenum’s redox properties play a significant role in chemical reactions.

In summary, ferromolybdenum powder, with its 60% iron content, is a valuable material due to its combination of iron’s strength and molybdenum’s superior performance characteristics. Its unique properties make it indispensable in various industries, from automotive to aerospace, where it contributes to enhanced strength, durability, and resistance to harsh conditions. The fine powder form ensures easy incorporation into different materials, providing superior performance in a wide range of applications.

(Ferromolybdenum Ferro Molybdenum Powder FeMo Powder 60%)

FAQs of Ferromolybdenum Ferro Molybdenum Powder FeMo Powder 60%

Inquiry us