Overview of Ferro-molybdenum Ferromolybdenum Ferromolybdenum Low Carbon Ferro-molybdenum Femo Lump Ferro Molybdenum Ferromolybdenum

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Ferro-molybdenum Ferromolybdenum Ferromolybdenum Low Carbon Ferro-molybdenum Femo Lump Ferro Molybdenum Ferromolybdenum

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Ferro-molybdenum Ferromolybdenum Ferromolybdenum Low Carbon Ferro-molybdenum Femo Lump Ferro Molybdenum Ferromolybdenum)

Parameters of Ferro-molybdenum Ferromolybdenum Ferromolybdenum Low Carbon Ferro-molybdenum Femo Lump Ferro Molybdenum Ferromolybdenum

Ferro-molybdenum, also known as ferromolybdenum, is a high-performance alloy that combines the properties of iron and molybdenum to create a unique material with exceptional strength, durability, and resistance to corrosion. This combination of elements makes it particularly valuable in various industrial applications where extreme conditions or high-temperature resistance is required.

Ferro-molybdenum is characterized by its low carbon content, which is crucial for maintaining its superior mechanical properties. The presence of carbon in excessive amounts can lead to brittleness, while a controlled amount ensures that the material retains its toughness and ductility. The low carbon content also allows for better weldability and workability during fabrication processes.

One of the key features of ferromolybdenum is its ability to withstand elevated temperatures without losing strength or undergoing significant deformation. This makes it ideal for use in industries such as aerospace, where components may be exposed to high temperatures during operation. It is often used in engine parts, turbine blades, and heat exchangers due to its excellent thermal stability.

Another notable characteristic is its exceptional resistance to wear and tear, especially under sliding friction conditions. This makes it suitable for applications like bearings, gears, and valve components where performance is essential. Additionally, ferromolybdenum exhibits good creep resistance, meaning it can maintain its shape and strength even under prolonged exposure to high stress without deforming.

The chemical composition of ferromolybdenum allows it to form a protective oxide layer on its surface, which acts as a natural barrier against corrosion. This property is highly beneficial in marine environments, chemical processing plants, and other corrosive atmospheres, where prolonged exposure to moisture and aggressive chemicals can degrade conventional materials.

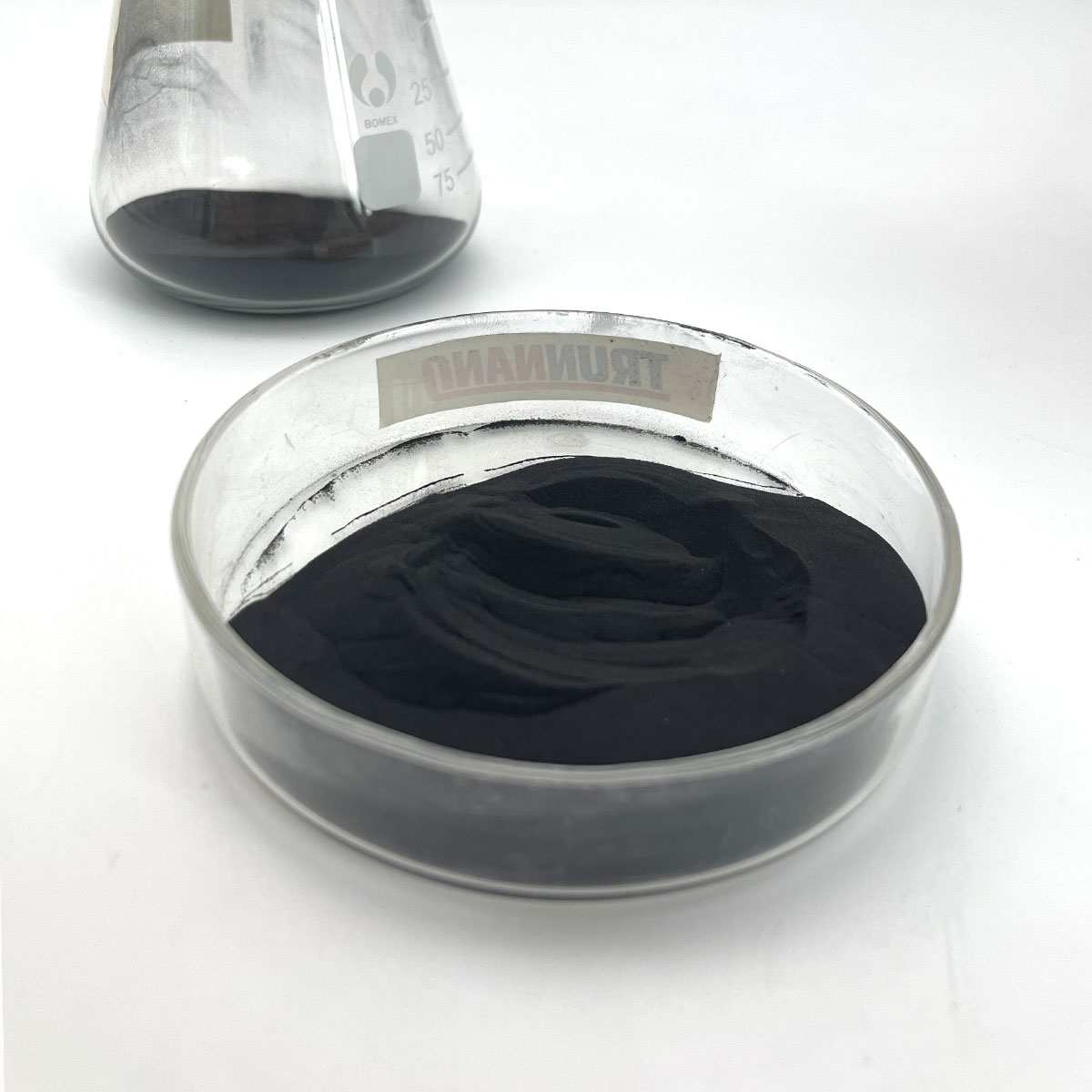

Ferro-molybdenum is available in different forms, including lumps, ingots, and powder, to cater to various manufacturing processes. The lump form is typically used for direct melting and casting, while the ingot form is more suitable for forging or rolling into sheets and bars. The powdered version is utilized in metal matrix composites, where it enhances the overall performance of the composite material.

In conclusion, ferromolybdenum is a versatile and robust material with a low carbon content that imparts exceptional strength, temperature resistance, wear resistance, and corrosion protection. Its wide range of applications spans from aerospace to automotive, power generation, and petrochemical industries, making it a critical component in modern engineering and manufacturing. With its inherent properties, ferromolybdenum continues to play a pivotal role in ensuring the reliability and longevity of various equipment and structures in challenging environments.

(Ferro-molybdenum Ferromolybdenum Ferromolybdenum Low Carbon Ferro-molybdenum Femo Lump Ferro Molybdenum Ferromolybdenum)

FAQs of Ferro-molybdenum Ferromolybdenum Ferromolybdenum Low Carbon Ferro-molybdenum Femo Lump Ferro Molybdenum Ferromolybdenum

Inquiry us