Overview of Factory Superfine Niobium Hydride Powder with Ultrafine Particle Size

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory Superfine Niobium Hydride Powder with Ultrafine Particle Size

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

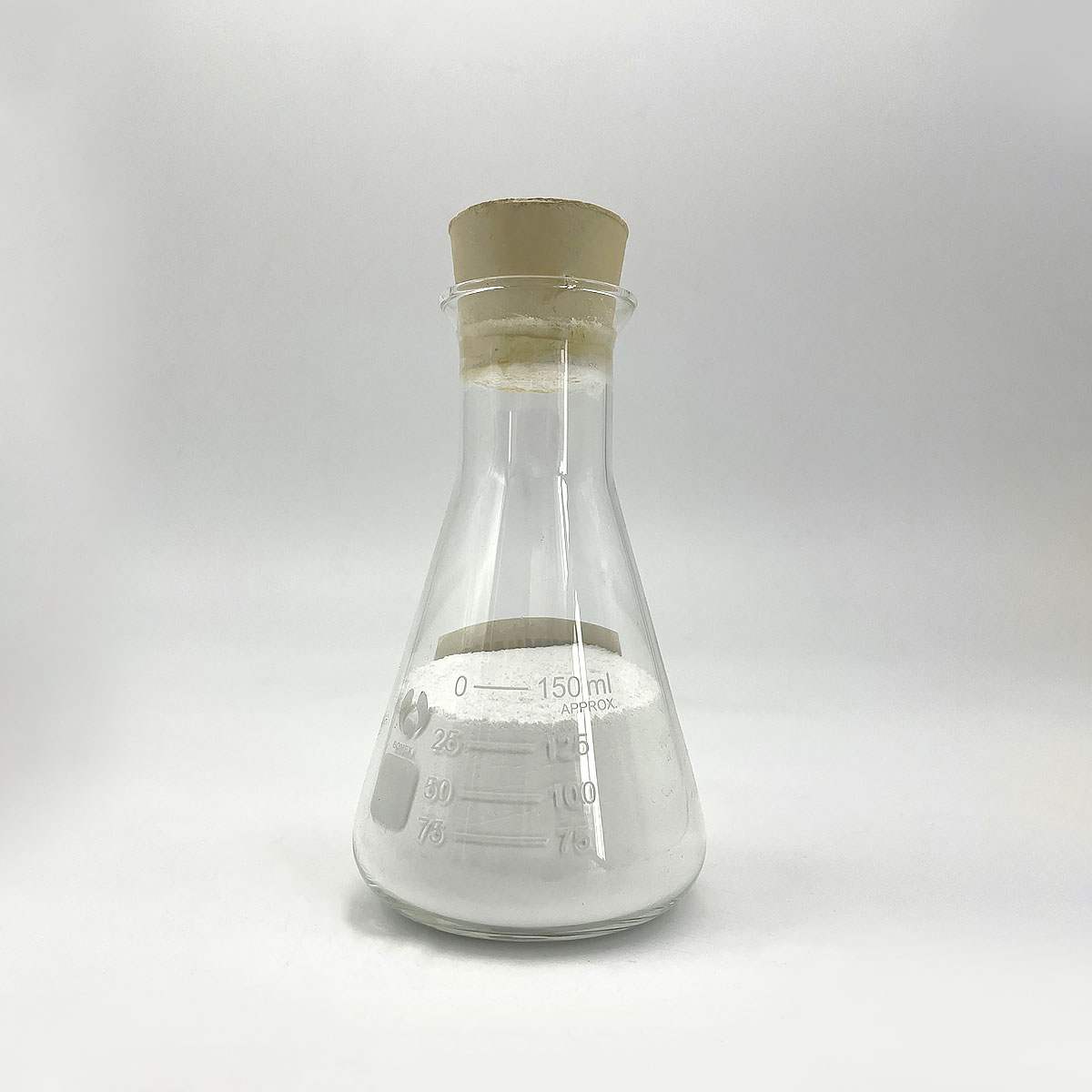

(Factory Superfine Niobium Hydride Powder with Ultrafine Particle Size)

Parameters of Factory Superfine Niobium Hydride Powder with Ultrafine Particle Size

Title: High-Purity Superfine Niobium Hydride Powder: An Advanced Material with Exceptional Fineness

Introduction:

In the realm of advanced materials science, a groundbreaking product emerges – superfine niobium hydride powder. This innovative material boasts an unparalleled particle size parameter that significantly enhances its properties and applications across various industries. With its unique characteristics, it is poised to revolutionize the way we utilize this compound in cutting-edge technologies.

Composition and Purity:

Niobium hydride, a compound formed by the chemical reaction between niobium and hydrogen, exhibits exceptional purity in our superfine form. The purity level ensures a high degree of consistency and reliability, making it ideal for demanding applications where impurities can compromise performance. Our manufacturing process rigorously adheres to strict quality control measures to deliver a material of the highest standards.

Particle Size and Fineness:

The defining feature of this superfine niobium hydride powder is its ultrafine particle size parameter. The particles are incredibly small, typically ranging from nanometers to micrometers, providing a large surface area-to-volume ratio. This attribute leads to enhanced reactivity, improved mechanical properties, and superior thermal conductivity. The fine particle structure also allows for better dispersion in various matrices, enabling efficient incorporation into composite materials and catalysts.

Applications:

This advanced material finds a wide array of applications due to its unique properties. In the aerospace industry, superfine niobium hydride can be used as a lightweight, strong reinforcement in composite structures, contributing to enhanced fuel efficiency and reduced weight. Electronics, particularly in superconducting devices, benefit from its high conductivity and stability at low temperatures. Additionally, it has potential in hydrogen storage technologies, where its hydride phase change capabilities hold promise for clean energy solutions.

Catalysis and Chemical Processing:

As a catalyst support, superfine niobium hydride powder enables enhanced catalytic activity in various chemical reactions. Its small particle size facilitates better contact with reactants, resulting in higher conversion rates and improved selectivity. In the petrochemical and refining sectors, it can optimize processes by providing an efficient platform for catalysts to perform their functions.

Superior Mechanical Properties:

The ultrafine particle structure of this niobium hydride powder contributes to remarkable mechanical properties. It exhibits excellent strength, ductility, and resistance to deformation, making it suitable for use in load-bearing components or in composite materials that require high-performance characteristics.

Environmental Impact and Sustainability:

Given its lightweight nature and ability to improve energy efficiency, superfine niobium hydride powder aligns with global efforts towards sustainability. Its potential use in green technologies like hydrogen storage and fuel cells contributes to a cleaner energy future.

Conclusion:

In summary, superfine niobium hydride powder is a game-changer in the materials science landscape. Its exceptional purity, ultrafine particle size, and versatile applications make it a sought-after material for industries ranging from aerospace to energy. As research and development continue to advance, the possibilities for this extraordinary compound are virtually limitless, paving the way for a new era of innovation and sustainable progress.

(Factory Superfine Niobium Hydride Powder with Ultrafine Particle Size)

FAQs of Factory Superfine Niobium Hydride Powder with Ultrafine Particle Size

Inquiry us