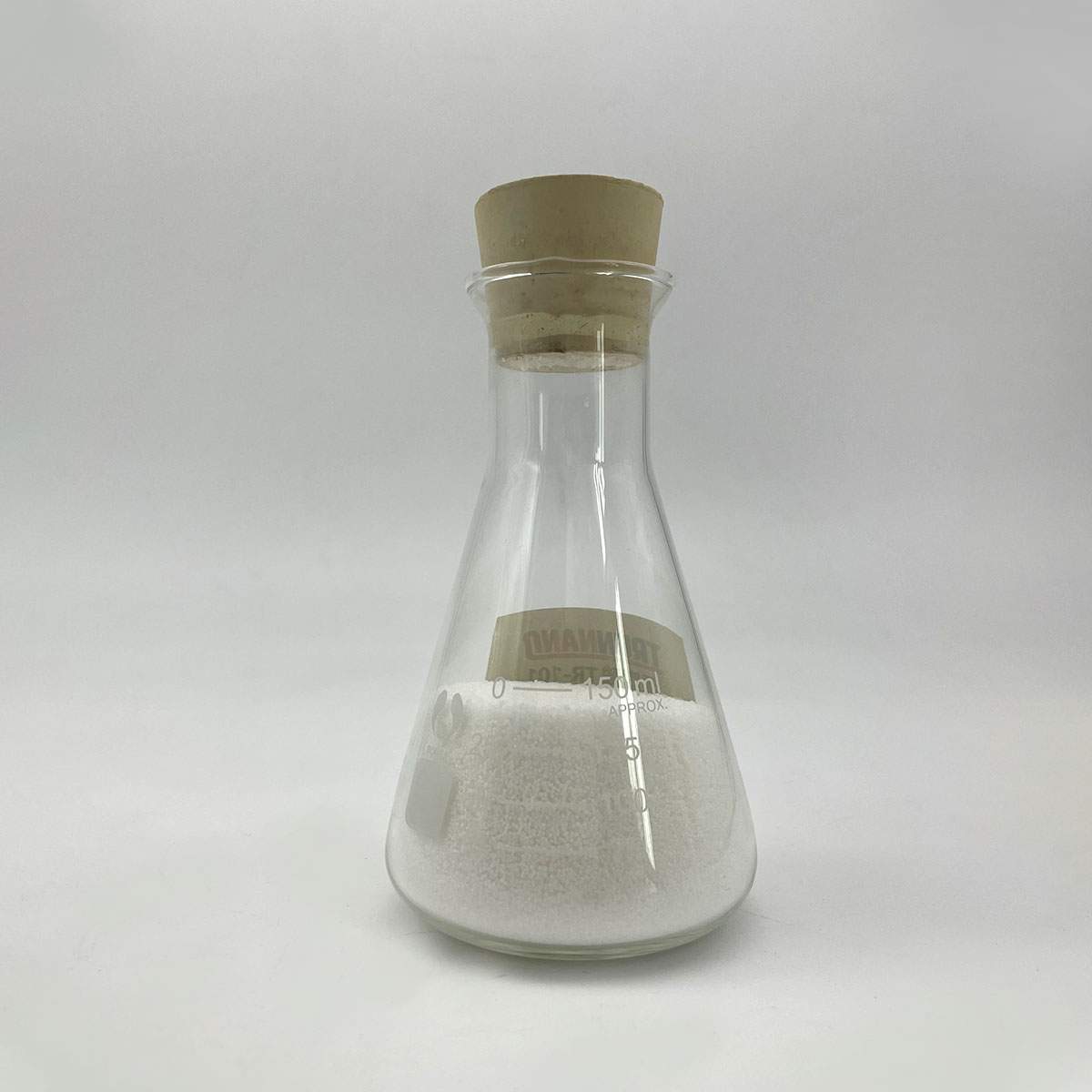

Overview of Factory promotion 1313-27-5 99% Molybdenum Oxide for Thermal Evaporation MoO3

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory promotion 1313-27-5 99% Molybdenum Oxide for Thermal Evaporation MoO3

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Factory promotion 1313-27-5 99% Molybdenum Oxide for Thermal Evaporation MoO3)

Parameters of Factory promotion 1313-27-5 99% Molybdenum Oxide for Thermal Evaporation MoO3

Title: Unmatched Excellence: 1313-27-5 99% Pure Molybdenum Oxide (MoO3) for High-Performance Thermal Evaporation Applications

Introduction:

In the realm of advanced materials and cutting-edge technology, our factory proudly presents a premium product that stands out as the epitome of performance – 1313-27-5 Molybdenum Oxide, a versatile compound with a remarkable 99% purity, specifically designed for thermal evaporation applications. This article delves into the exceptional properties, benefits, and the unparalleled role it plays in various industries.

Composition and Purity:

The heart of our offering is 1313-27-5, which refers to the Chemical Abstracts Service (CAS) registry number for molybdenum oxide. Our commitment to quality is exemplified by the 99% purity level, ensuring the highest standards in material integrity. This high concentration minimizes impurities, maximizing efficiency and effectiveness during thermal evaporation processes.

Thermal Conductivity and Stability:

Molybdenum oxide, or MoO3, boasts exceptional thermal conductivity, making it an ideal choice for applications where heat transfer is crucial. Its stability under elevated temperatures ensures reliable performance even in demanding conditions, such as in vacuum chambers and electron beam evaporators. This property enables efficient energy conversion and precise control over deposition rates, essential for thin film fabrication and surface modification.

Applications:

The versatility of 1313-27-5 Molybdenum Oxide extends across a wide range of industries, including microelectronics, photovoltaics, and optical coatings. In the semiconductor industry, it is employed for depositing molybdenum layers, enhancing device performance and reliability. In solar cells, it facilitates the formation of anti-reflection coatings, improving light absorption and overall efficiency. Optical applications benefit from its high refractive index and low absorption coefficients, contributing to the development of high-quality lenses and filters.

Advantages and Efficiency:

Our pure MoO3 offers several advantages over alternative materials. Its superior purity reduces the formation of unwanted side-products, minimizing process downtime and waste. The controlled particle size and morphology ensure a uniform deposition, leading to enhanced film quality and consistency. Moreover, the long-term stability of MoO3 ensures consistent performance over extended periods, saving on maintenance costs and improving overall productivity.

Ease of Use and Customization:

We provide our 1313-27-5 Molybdenum Oxide in various formats, tailored to meet the specific requirements of our clients. Whether you need powders, pellets, or target forms, our dedicated team can accommodate your preferences, ensuring a seamless integration into your existing processes.

Conclusion:

In conclusion, our 1313-27-5 99% Molybdenum Oxide is a game-changer in thermal evaporation applications. With its unparalleled combination of thermal conductivity, stability, and purity, it empowers industries to push the boundaries of innovation. Trust our factory’s commitment to delivering top-quality materials that drive progress and optimize performance. Contact us today to experience the difference that 1313-27-5 MoO3 can make in your operations.

(Factory promotion 1313-27-5 99% Molybdenum Oxide for Thermal Evaporation MoO3)

FAQs of Factory promotion 1313-27-5 99% Molybdenum Oxide for Thermal Evaporation MoO3

Inquiry us