Overview of Factory Nano Molybdenum Powder Mo Nanoparticle

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory Nano Molybdenum Powder Mo Nanoparticle

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

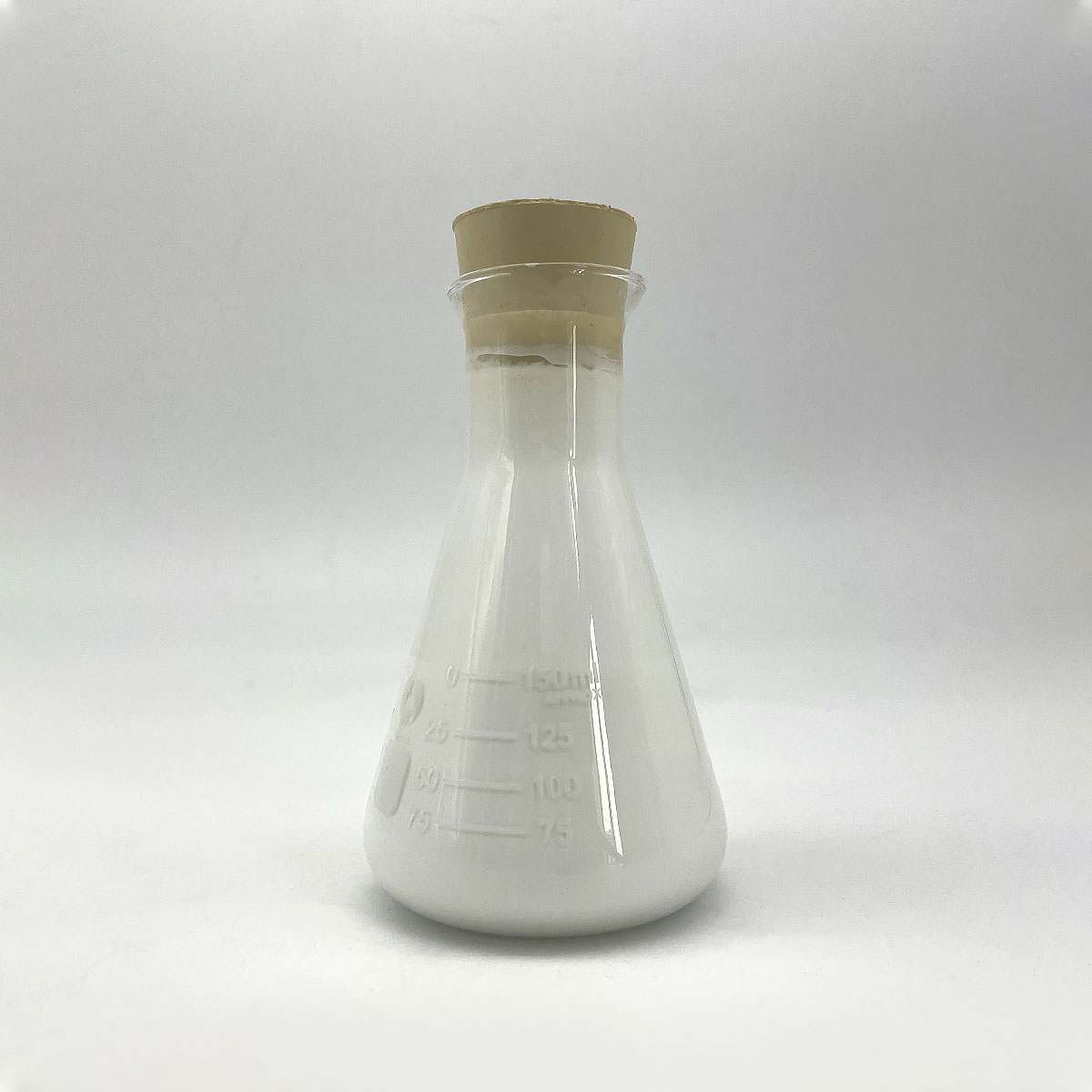

(Factory Nano Molybdenum Powder Mo Nanoparticle)

Parameters of Factory Nano Molybdenum Powder Mo Nanoparticle

Molybdenum Nanoparticles, also known as Mo Nanoparticles or MoNPs, are an advanced form of molybdenum material that have been processed down to the nanoscale, typically ranging from 1 to 100 nanometers in size. These particles exhibit unique properties due to their small size and high surface-to-volume ratio, which significantly differ from their bulk counterparts. Here, we’ll discuss some key parameters of Factory Nano’s molybdenum nanopowder without adhering to a specific format.

1. **Particle Size Distribution (PSD):** Factory Nano’s MoNPs have a narrow PSD, ensuring a consistent particle size across the batch. This is crucial for maintaining uniform reactivity and performance in various applications.

2. **Purity: **The purity of our molybdenum nanopowder is typically above 99.9%, minimizing impurities that could affect the desired properties of the material.

3. **Crystal Structure:** Monocrystalline or polycrystalline, depending on the manufacturing process, these particles exhibit a well-defined crystal structure, which influences their mechanical strength, thermal stability, and electronic properties.

4. **Surface Area: **Due to their nano-scale dimensions, MoNPs have a high surface area, which enhances their catalytic activity, chemical reactivity, and sorption capacity.

5. **Density: **The density of MoNPs is lower than bulk molybdenum, making them lightweight and easier to disperse in various matrices.

6. **Thermal Conductivity: **Nanoparticles generally have lower thermal conductivity compared to their bulk form, but MoNPs can still maintain reasonable heat transfer capabilities, which is essential in thermal management applications.

7. **Mechanical Properties: **The mechanical strength of MoNPs may be enhanced or reduced, depending on the degree of crystallinity and dispersion within a matrix. They can be tailored for applications requiring improved wear resistance or increased ductility.

8. **Electrical Conductivity: **Molybdenum is a good electrical conductor, and its nanoscale form retains this property. This makes MoNPs suitable for applications in electronics, supercapacitors, and sensors.

9. **Chemical Stability: **Nanoparticles can exhibit enhanced chemical stability compared to larger particles, making them resistant to corrosion and oxidation in certain environments.

10. **Application Potential: **Factory Nano’s MoNPs find applications in various sectors such as aerospace, automotive, energy storage, catalysts, coatings, and biomedical devices. Their unique properties enable them to improve efficiency, durability, and performance in these areas.

In conclusion, Factory Nano’s molybdenum nanopowder offers a versatile material with tailored properties due to its nanoscale nature. The careful control over size, structure, and purity ensures high-quality products for a wide range of industrial applications. As research and technology continue to advance, the potential uses for MoNPs will likely expand, driving innovation in numerous industries.

(Factory Nano Molybdenum Powder Mo Nanoparticle)

FAQs of Factory Nano Molybdenum Powder Mo Nanoparticle

Inquiry us