Overview of Factory Molybdenum Disulfide MoS2 Powder 15um for Lubricant

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory Molybdenum Disulfide MoS2 Powder 15um for Lubricant

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

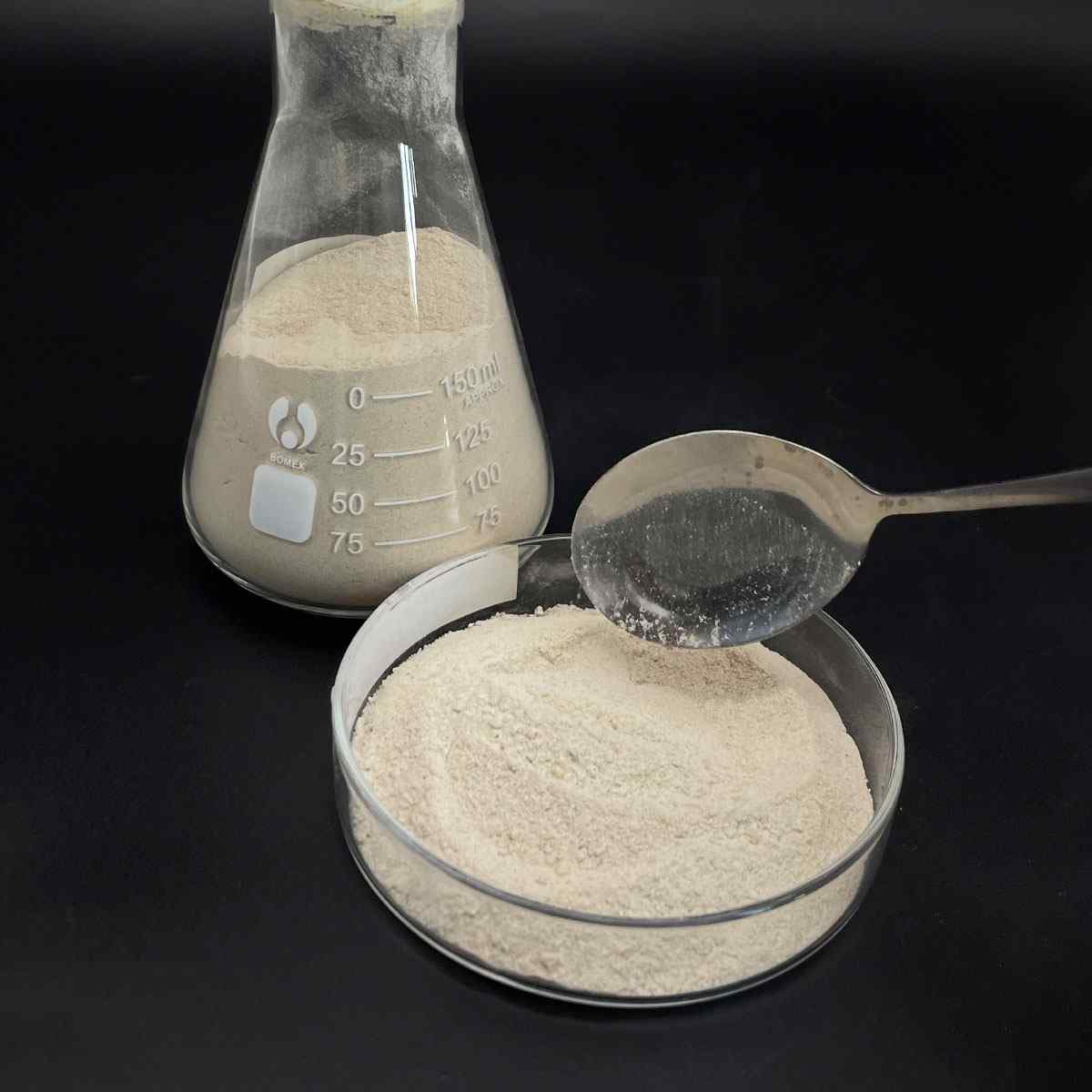

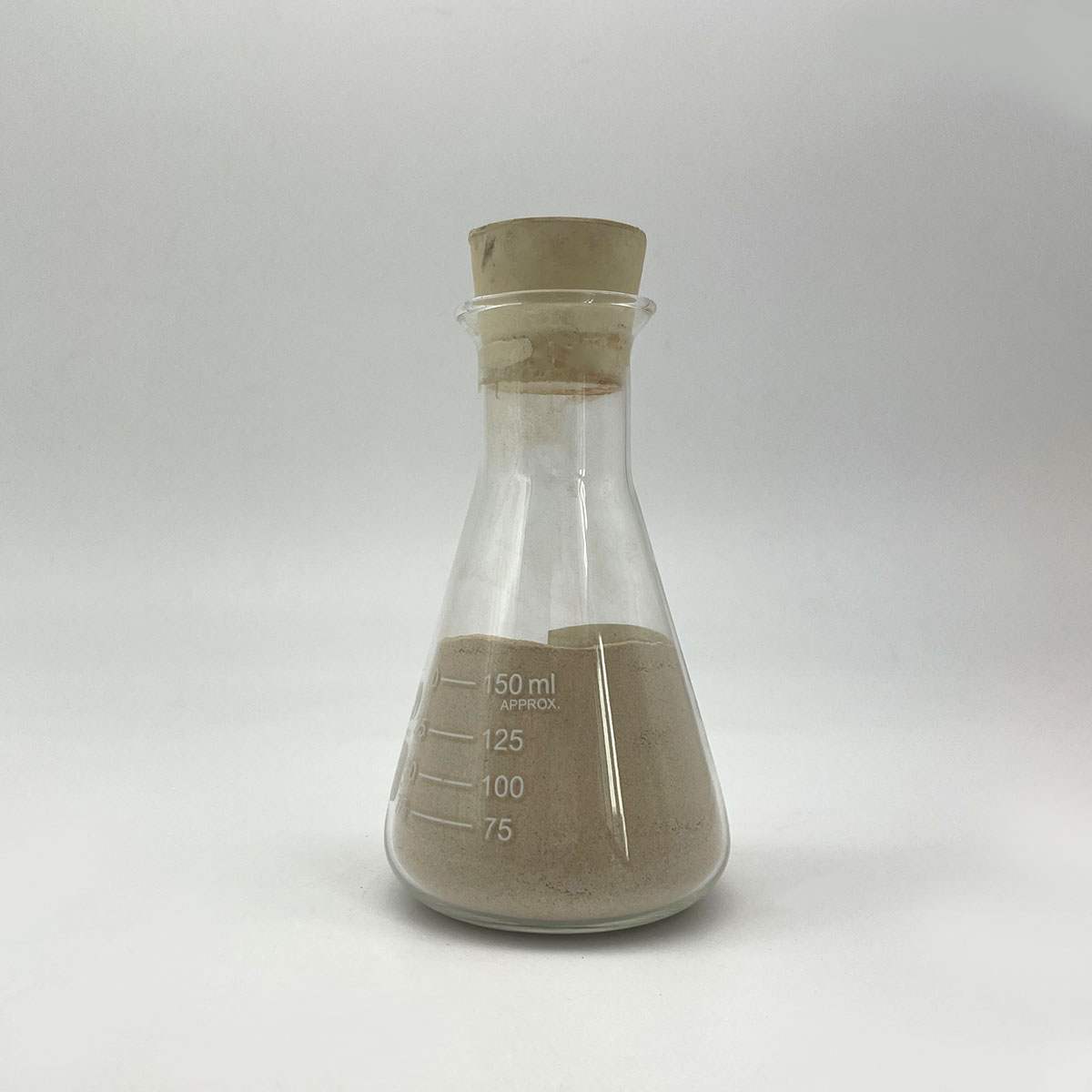

(Factory Molybdenum Disulfide MoS2 Powder 15um for Lubricant)

Parameters of Factory Molybdenum Disulfide MoS2 Powder 15um for Lubricant

Title: An Insight into Factory-Produced Molybdenum Disulfide (MoS2) Powder for High-Performance Lubricants – 15 micron Particle Size

Molybdenum disulfide (MoS2), a renowned industrial material, has found exceptional applications in the field of lubrication due to its unique properties. At our factory, we specialize in producing high-quality MoS2 powder with a particle size of 15 micrometers, specifically tailored for advanced lubricant formulations. This particular particle size offers unparalleled advantages in enhancing lubricant performance.

Molybdenum disulfide is a lamellar crystal structure that exhibits exceptional lubricity, wear resistance, and thermal stability. The 15 micron particles provide an ideal balance between surface coverage and ease of dispersion within lubricating oils. These smaller particles ensure better film formation, reducing friction and preventing wear on machinery at high temperatures and under heavy loads.

One of the key features of our 15 micron MoS2 powder is its low coefficient of friction. This property allows for smoother operation, resulting in reduced energy consumption and extended equipment life. It forms a self-lubricating layer that acts as a protective shield against abrasive forces, thereby minimizing wear and tear.

In addition to its tribological benefits, MoS2 is known for its excellent chemical inertness. It resists corrosion and degradation under various environmental conditions, making it suitable for use in harsh environments such as extreme temperatures, moisture, or chemical exposure. This durability ensures consistent performance over time, saving maintenance costs and downtime.

Our 15 micron MoS2 powder also improves the viscosity index of lubricants, enabling them to maintain optimal flow characteristics across a wide temperature range. This adaptability is crucial for industries operating in fluctuating temperature conditions, such as automotive, aerospace, and manufacturing.

Furthermore, our factory follows stringent quality control measures to guarantee the purity and consistency of the product. We adhere to international standards for particle size distribution, morphology, and elemental analysis, ensuring that each batch meets the highest industry requirements.

In conclusion, our factory-produced 15 micron Molybdenum Disulfide powder is a game-changer in lubricant technology. Its superior lubricity, wear resistance, thermal stability, and compatibility with various applications make it an indispensable additive. By incorporating this high-performance material into your lubricant formulations, you can expect enhanced efficiency, longer equipment life, and reduced operational costs. Trust us to deliver the highest quality MoS2 powder to meet your specific lubrication needs.

(Factory Molybdenum Disulfide MoS2 Powder 15um for Lubricant)

FAQs of Factory Molybdenum Disulfide MoS2 Powder 15um for Lubricant

Inquiry us