Overview of Factory Direct 99.7% 99.9% purity sponge titanium sponge metal raw material titanium other titanium

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Factory Direct 99.7% 99.9% purity sponge titanium sponge metal raw material titanium other titanium

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Factory Direct 99.7% 99.9% purity sponge titanium sponge metal raw material titanium other titanium)

Parameters of Factory Direct 99.7% 99.9% purity sponge titanium sponge metal raw material titanium other titanium

Title: Factory-Direct High Purity Sponge Titanium Raw Material: A Comprehensive Overview

Introduction:

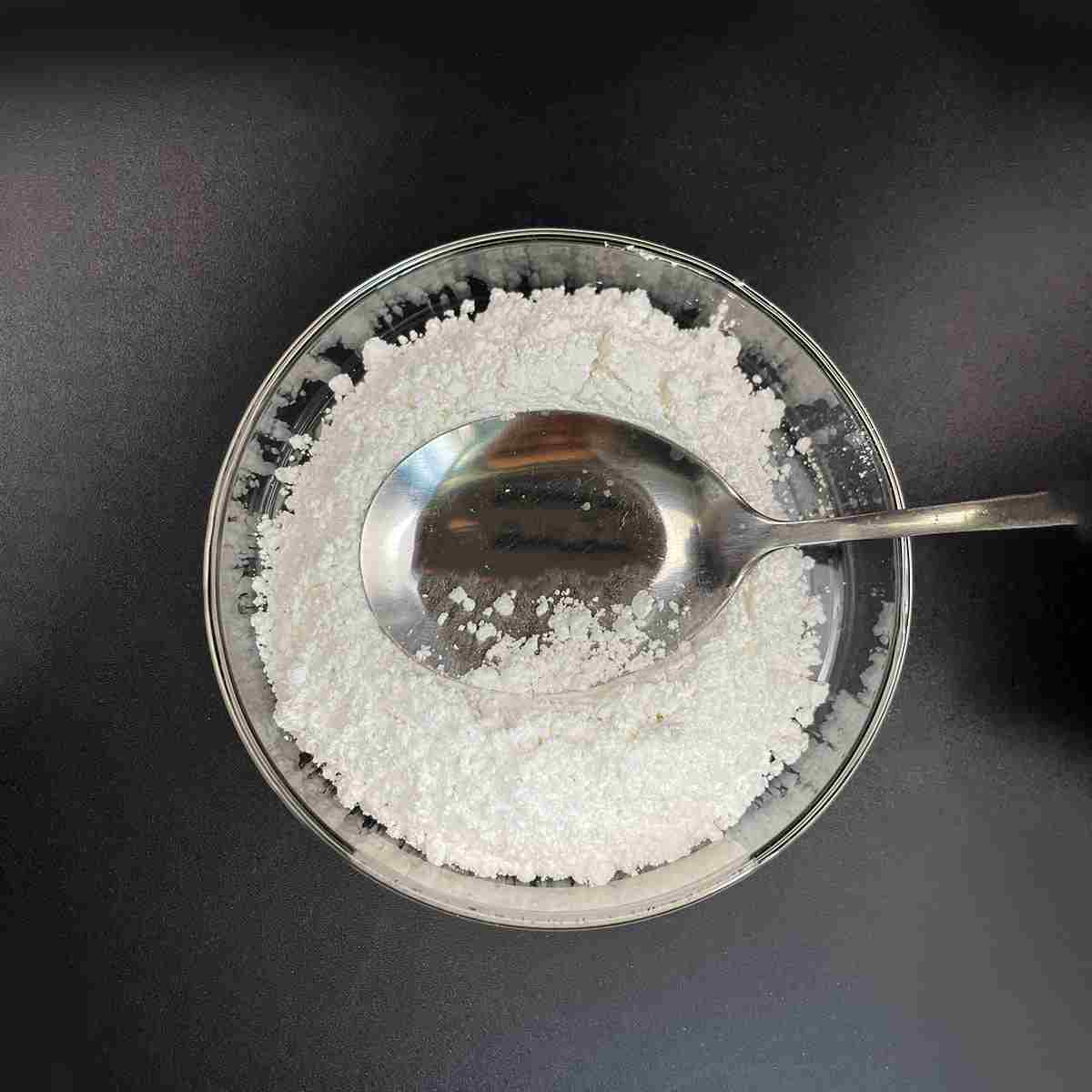

Sponge titanium, a highly sought-after metallic raw material, is renowned for its exceptional purity levels and versatile applications across various industries. Our factory-direct offering boasts a purity range of 99.7% and 99.9%, ensuring the highest quality for your projects. This detailed explanation will delve into the key parameters and characteristics of this extraordinary product.

1. Composition:

The primary component of sponge titanium is titanium (Ti), an element with the atomic number 22 and the chemical symbol Ti. It belongs to the group IVB in the periodic table, known for its lightweight, corrosion-resistant nature, and high strength-to-weight ratio. The trace impurities in our sponge titanium are carefully controlled to maintain the desired purity standards.

2. Manufacturing Process:

Our sponge titanium is produced through a proprietary process that starts with titanium dioxide (TiO2) as the primary raw material. This involves a series of steps, including electrolysis, reduction, and purification, to transform the oxide into the pure metal. The resulting sponge-like structure is formed due to the gaseous byproducts leaving behind a porous material ideal for various applications.

3. Purity Levels:

The purity grades we offer – 99.7% and 99.9% – signify the titanium content in the final product. A 99.7% purity indicates that only 0.3% of impurities are present, making it suitable for general-purpose applications. The 99.9% purity grade represents an even higher level, with less than 0.1% impurities, making it ideal for demanding industries like aerospace, medical devices, and chemical processing.

4. Physical Properties:

Sponge titanium is characterized by its lightweight, silver-gray appearance, and low density compared to steel. It has excellent mechanical properties, such as high strength (yielding around 450 MPa), good ductility, and resistance to corrosion. Its unique porous structure also contributes to its ability to be machined easily and offers thermal and acoustic insulation.

5. Applications:

This high-purity sponge titanium finds extensive use in a wide array of industries. Key applications include:

– Aerospace: Lightweight components for aircraft, missiles, and space vehicles due to its strength and durability.

– Medical Devices: Biocompatible implants, surgical tools, and dental materials.

– Chemical Processing: Reactors, catalyst supports, and heat exchangers due to its corrosion resistance.

– Automotive: Lightweight engine parts and exhaust systems.

– Electronics: Shielding and packaging materials due to its electromagnetic shielding properties.

6. Environmental Impact and Sustainability:

Our sponge titanium is environmentally friendly, as the production process minimizes waste and adheres to strict environmental regulations. The recycling potential of titanium makes it a sustainable choice for industries seeking eco-friendly alternatives.

Conclusion:

Factory Direct’s 99.7% and 99.9% purity sponge titanium raw material represents a reliable and high-quality option for various applications. With its exceptional properties and versatility, it offers a competitive advantage to businesses seeking the best in performance and reliability. Trust us to deliver the precise material you need for your next project, backed by our commitment to excellence and customer satisfaction.

(Factory Direct 99.7% 99.9% purity sponge titanium sponge metal raw material titanium other titanium)

FAQs of Factory Direct 99.7% 99.9% purity sponge titanium sponge metal raw material titanium other titanium

Inquiry us