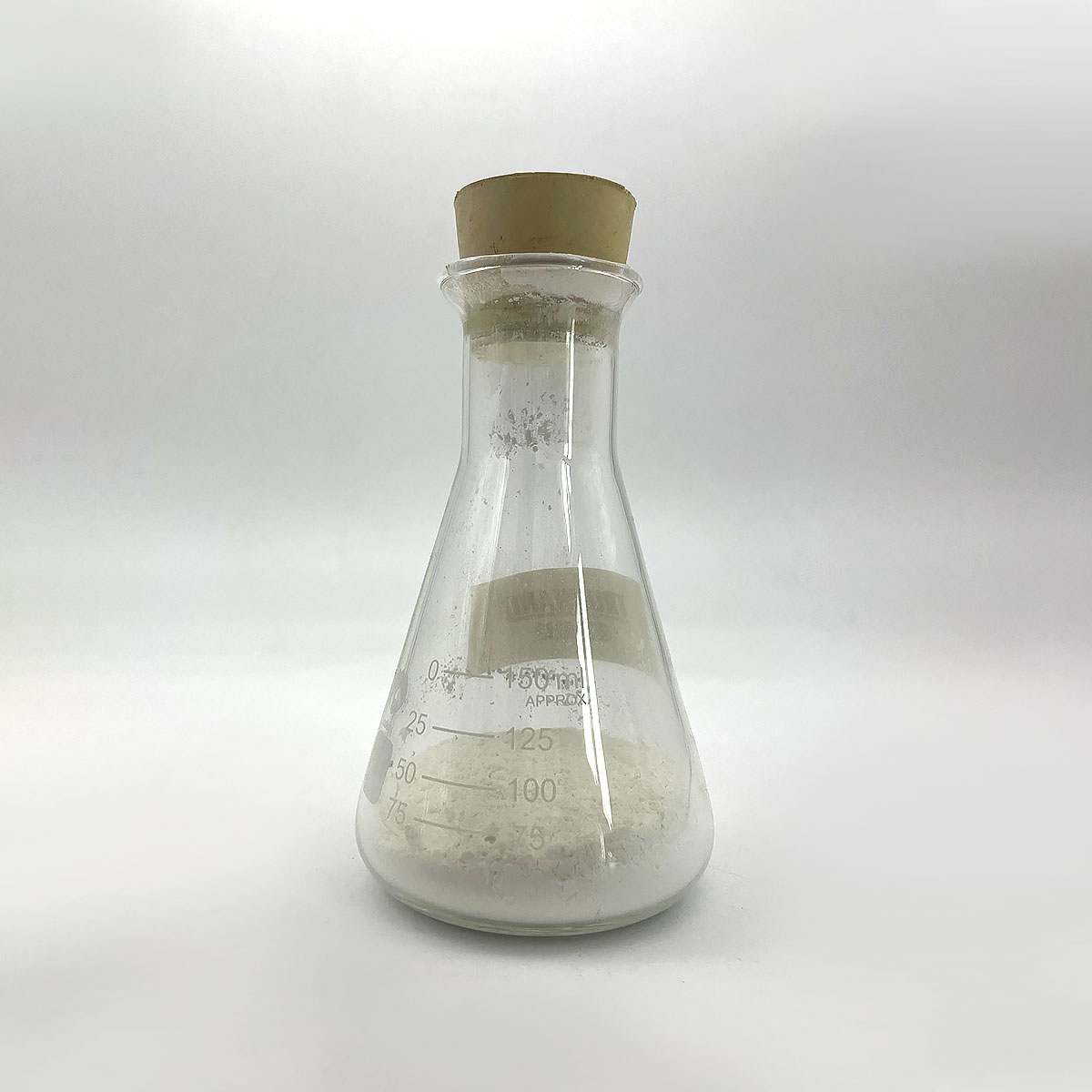

Overview of Export Niobium oxide Nb2O5 r sputtering target

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Export Niobium oxide Nb2O5 r sputtering target

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Export Niobium oxide Nb2O5 r sputtering target)

Parameters of Export Niobium oxide Nb2O5 r sputtering target

Niobium oxide (Nb2O5), a crucial material in various industrial applications, is a high-purity compound that finds extensive use in thin film deposition processes, particularly in the field of microelectronics and optical coatings. As an r-sputtering target, it plays a pivotal role in depositing niobium-based films for superconductors, capacitors, and optoelectronic devices.

The r-sputtering process involves the use of radiofrequency (RF) or direct current (DC) to sputter atoms from the target surface, which are then incorporated into a substrate to form a thin film. The Niobium oxide target’s parameters are essential for achieving optimal film properties and minimizing impurities. Here are some key parameters:

1. **Material purity**: Purity of Nb2O5 is crucial, typically above 99.99% (4N), to ensure minimal contamination and high-performance films. Impurities can degrade the superconducting properties or introduce unwanted optical effects.

2. **Crystal structure**: The target material should have a well-defined crystal structure, usually cubic or monoclinic, to facilitate uniform deposition. The phase purity is important for maintaining the desired properties in the deposited film.

3. **Density and porosity**: A dense and homogeneous target with low porosity ensures efficient sputtering and a consistent film thickness. The density can be around 6.2 g/cm³, and a controlled porosity is necessary to maintain target integrity during sputtering.

4. **Particle size**: The particle size within the target affects the energy distribution and sputtering yield. Generally, smaller particles lead to higher sputtering rates, but larger particles may result in smoother films. A typical particle size range is between 50-100 µm.

5. **Sputtering power and pressure**: The RF or DC power applied to the target and the working pressure inside the sputtering chamber determine the deposition rate and film quality. A balance must be struck between maximizing yield and minimizing defects. Power levels can range from a few hundred watts to several kilowatts, while pressures are often kept below 1 mTorr for better vacuum conditions.

6. **Temperature**: The temperature of the target affects its stability and sputtering efficiency. Niobium oxide targets are typically operated at room temperature or slightly elevated temperatures to prevent degradation and maintain a stable sputtering rate.

7. **Target geometry**: Targets can be cylindrical, rectangular, or even in the form of a multi-target system, depending on the application requirements. The shape and dimensions influence the deposition uniformity and overall efficiency.

8. **Life expectancy**: The target’s lifespan depends on factors like sputtering conditions, material quality, and usage frequency. For high-quality targets, the expected life can range from several hundred to thousands of hours.

9. **Cooling system**: Adequate cooling is necessary to manage the heat generated during sputtering, preventing thermal stress and target damage. Water cooling or cryogenic cooling methods may be employed, depending on the power levels.

In conclusion, the performance and efficiency of Niobium oxide (Nb2O5) as an r-sputtering target depend on a combination of material purity, crystal structure, and carefully controlled sputtering parameters. Optimizing these parameters is critical to achieving the desired film properties for various applications in electronics, superconductivity, and optics.

(Export Niobium oxide Nb2O5 r sputtering target)

FAQs of Export Niobium oxide Nb2O5 r sputtering target

Inquiry us