Overview of Customization Powder Metallurgy Parts Tungsten Counterweights Metal Injection Molding Mim Parts

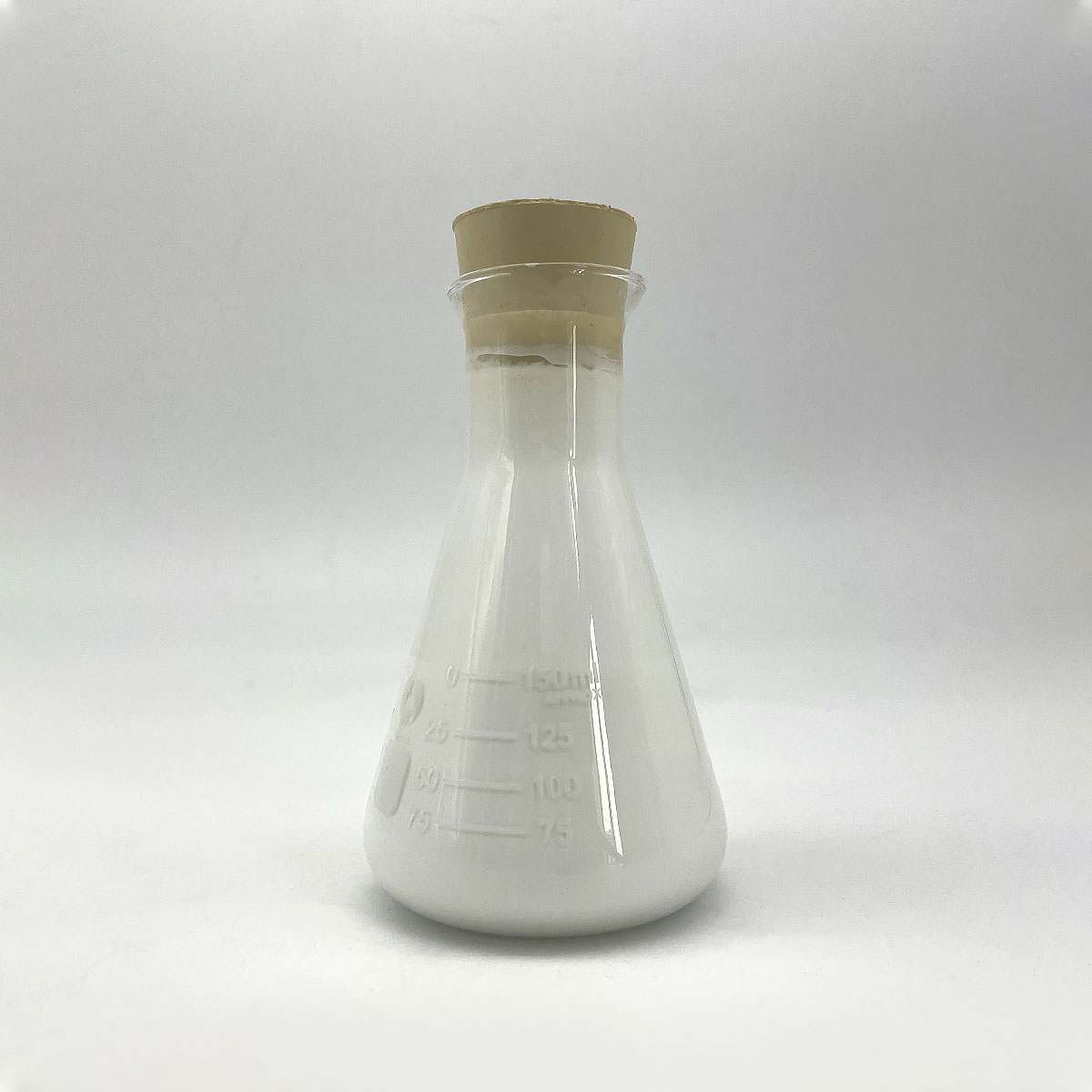

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Customization Powder Metallurgy Parts Tungsten Counterweights Metal Injection Molding Mim Parts

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Customization Powder Metallurgy Parts Tungsten Counterweights Metal Injection Molding Mim Parts)

Parameters of Customization Powder Metallurgy Parts Tungsten Counterweights Metal Injection Molding Mim Parts

Powder Metallurgy (PM) is a versatile and innovative manufacturing process that offers exceptional customization for tungsten counterweights and metal injection molded (MIM) parts. These components are designed to meet the specific requirements of various industries, including aerospace, automotive, and precision engineering, where weight reduction, strength, and durability are paramount.

Tungsten, known for its high density and exceptional strength-to-weight ratio, is the primary material choice for PM counterweights. Tungsten-based alloys provide unparalleled performance in applications where inertia and balance play a critical role, such as in aircraft engines or high-speed machinery. The customization process begins with selecting the appropriate tungsten powder, which can be tailored to have varying compositions to achieve desired properties like hardness, wear resistance, or thermal stability.

In PM, tungsten powder is mixed with a binder, compacted into pre-forms, and then sintered at elevated temperatures to form a solid, dense structure. This method allows for intricate geometries and complex shapes that would be challenging or impossible to produce using traditional casting methods. The level of customization extends to surface finish, tolerances, and even functional features like cooling channels or threading, all controlled through the sintering parameters.

Metal Injection Molding (MIM), on the other hand, combines the benefits of PM with the precision and accuracy of plastic injection molding. It involves melting tungsten particles and injecting them into a mold under high pressure, where they solidify and cool to form the final part. MIM tungsten components offer exceptional dimensional accuracy, smooth surfaces, and seamless integration with existing manufacturing processes.

The key parameters for both PM tungsten counterweights and MIM mim parts include:

1. Particle size: The size of the tungsten powder affects the final part’s density, strength, and surface finish. Smaller particles result in better density but may require higher sintering temperatures.

2. Composition: Customizing the tungsten alloy composition can alter the mechanical properties, such as hardness, wear resistance, and thermal conductivity.

3. Binder type and content: The choice of binder determines the ease of forming and sintering, while the optimal amount ensures complete densification during processing.

4. Sintering conditions: Temperature, time, and atmosphere play crucial roles in achieving the desired microstructure and mechanical properties. Each application may require specific sintering profiles.

5. Injection molding parameters: Factors like melt temperature, injection pressure, and cooling rates impact the quality, dimensional stability, and surface finish of MIM parts.

6. Post-processing treatments: These may include heat treatment, polishing, or surface coatings to enhance functionality and appearance.

In summary, Powder Metallurgy and Metal Injection Molding of tungsten parts offer a high degree of customization, enabling engineers to create lightweight, strong, and precise counterweights and components for demanding applications. By carefully controlling the process parameters, manufacturers can tailor these parts to meet unique specifications, making them indispensable in modern engineering solutions.

(Customization Powder Metallurgy Parts Tungsten Counterweights Metal Injection Molding Mim Parts)

FAQs of Customization Powder Metallurgy Parts Tungsten Counterweights Metal Injection Molding Mim Parts

Inquiry us