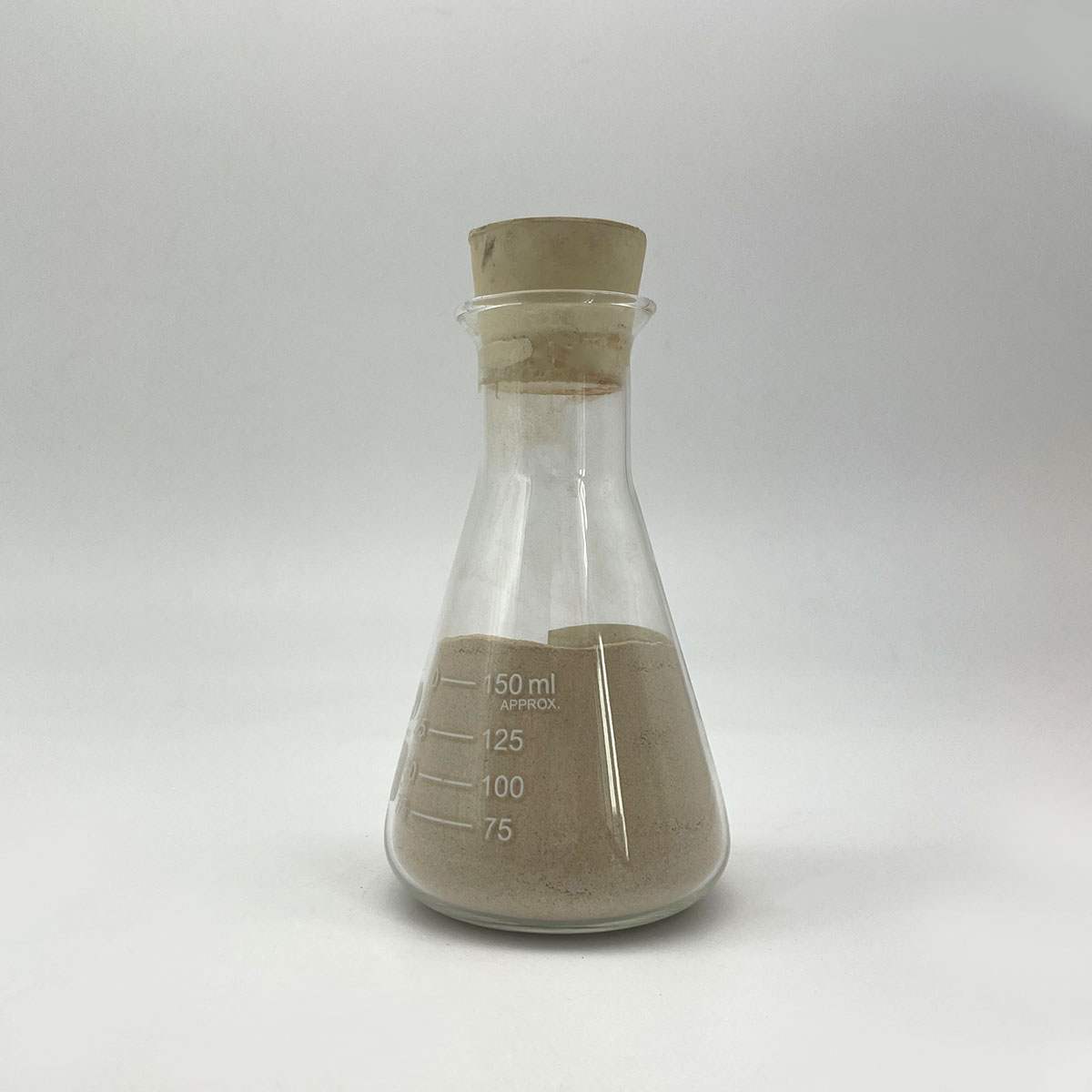

Overview of Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide)

Parameters of Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide

Title: A Comprehensive Overview of 90Ta-10Nb Tantalum Carbide/Niobium Carbide Compound Powder: Material Properties and Applications

Tantalum carbide (TaC) and niobium carbide (NbC) are high-performance ceramic materials that have gained significant attention due to their exceptional mechanical, thermal, and wear-resistant properties. The compound powder with a 90% tantalum and 10% niobium composition, often referred to as 90Ta/10Nb, offers a unique blend of characteristics that make it an attractive material in various industries.

Firstly, let’s delve into the chemical composition. Tantalum carbide is a refractory compound, with tantalum providing high melting points and excellent electrical conductivity, while niobium adds ductility and toughness. The 90:10 ratio ensures a balance between these properties, making the composite powder suitable for applications where strength and stability are crucial.

One of the primary advantages of 90Ta/10Nb compound powder is its hardness. It boasts a Vickers hardness of around 2800 HV, which is significantly higher than that of steel, making it ideal for wear-resistant applications such as cutting tools, bearings, and gears. The combination of tantalum’s extreme hardness and niobium’s ability to maintain toughness under high loads enhances its performance in demanding environments.

Thermal stability is another key feature of this material. Tantalum carbide has a high melting point of around 3250°C, while niobium carbide adds a marginally lower melting point but retains good thermal conductivity. This results in a compound that can withstand elevated temperatures without degrading, making it suitable for applications in aerospace, automotive, and power generation sectors where heat resistance is vital.

The 90Ta/10Nb powder also exhibits excellent tribological properties, meaning it has low coefficients of friction and high wear resistance. This makes it ideal for use in sliding bearings, seals, and coatings, where frictional losses and wear-induced damage must be minimized. Additionally, the material’s self-lubricating nature reduces the need for external lubricants, contributing to longer component lifetimes.

In terms of machinability, the 90Ta/10Nb compound powder can be processed using techniques like sintering, milling, or spark plasma sintering, allowing for customization into various shapes and sizes. Its good thermal conductivity facilitates rapid cooling during manufacturing processes, reducing the risk of microstructural defects and enhancing dimensional accuracy.

Furthermore, the 90Ta/10Nb composition exhibits good creep resistance, which is crucial in applications subjected to long-term stress at elevated temperatures. This property is particularly useful in the nuclear industry, where components operating under harsh conditions require materials that can maintain integrity over extended periods.

However, it’s important to note that the compound powder may not be suitable for all applications due to its inherent brittleness. It is essential to consider the specific requirements of each application and perform thorough testing to ensure the material’s compatibility and effectiveness.

In conclusion, the 90Ta-10Nb Tantalum Carbide/Niobium Carbide compound powder is a high-performance material with a unique blend of properties, including hardness, thermal stability, wear resistance, and machinability. Its versatility makes it a valuable choice for industries ranging from aerospace to automotive, where durability and efficiency are paramount. However, careful consideration of the application’s specific needs is necessary to fully leverage the benefits of this advanced ceramic material.

(Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide)

FAQs of Compound Carbide Powder 90Ta 10Nb 90/10 Tantalum Carbide/Niobium Carbide

Inquiry us