Overview of CAS 12058-18-3 Superfine 325 Mesh Molybdenum Diselenide Powder MoSe2 Powder

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

Features of CAS 12058-18-3 Superfine 325 Mesh Molybdenum Diselenide Powder MoSe2 Powder

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(CAS 12058-18-3 Superfine 325 Mesh Molybdenum Diselenide Powder MoSe2 Powder)

Parameters of CAS 12058-18-3 Superfine 325 Mesh Molybdenum Diselenide Powder MoSe2 Powder

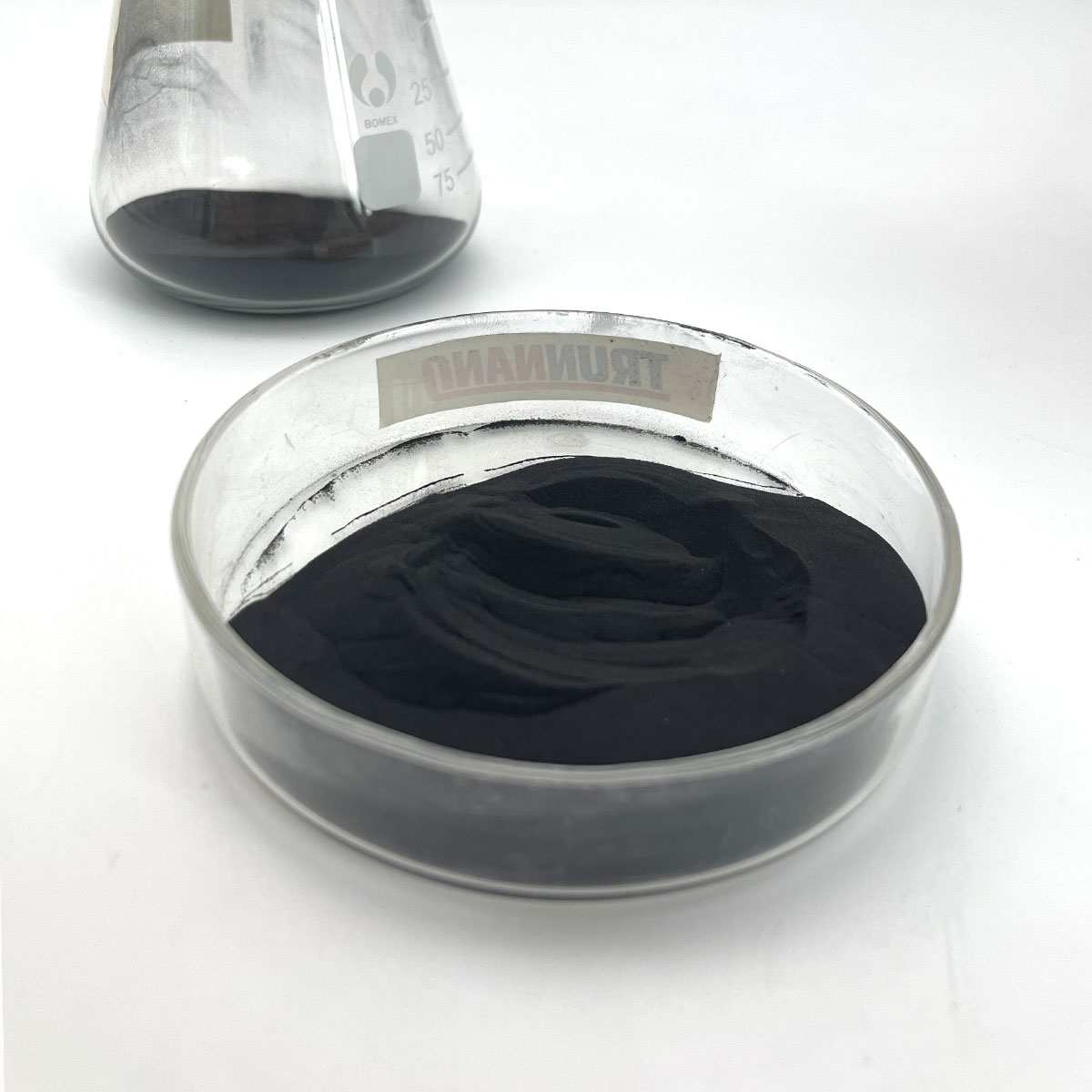

Molybdenum diselenide (MoSe2), with the chemical formula CAS No. 12058-18-3, is a fascinating inorganic compound that has gained significant attention in various industries due to its exceptional properties. This material exists as a layered crystal structure, primarily in the form of a black, shiny powder. When processed into a superfine 325 mesh particle size, it offers unique characteristics that make it highly desirable.

Superfine 325 mesh MoSe2 powder boasts an incredibly small particle size, which enhances its surface area and reactivity. This finer grain structure allows for better dispersion and interaction with other materials, making it an ideal choice for applications requiring enhanced catalytic or electronic performance. The 325 mesh grading ensures consistent particle uniformity, crucial for maintaining reliable performance across different processes.

One of the key features of molybdenum diselenide is its semiconducting nature, which makes it suitable for use in advanced electronic devices such as transistors, solar cells, and sensors. Its bandgap, around 1.2 eV, allows it to function effectively in optoelectronic applications where light absorption and conversion are essential. The superfine particles enhance the efficiency of these devices by facilitating faster charge carrier transport and improved light scattering.

Moreover, MoSe2 possesses remarkable mechanical strength and thermal stability, making it an attractive material for lubricants and wear-resistant coatings. Its high melting point, approximately 1,227°C, ensures durability under extreme conditions. As a result, it finds applications in aerospace, automotive, and industrial machinery where friction reduction and heat resistance are critical factors.

In the field of energy storage, MoSe2 is used as a cathode material in lithium-ion batteries due to its excellent electrochemical properties. Its layered structure enables efficient lithium-ion insertion and extraction, contributing to higher capacity and longer cycle life. The superfine 325 mesh powder further optimizes battery performance by providing rapid charge transfer and minimizing the formation of large aggregates.

Additionally, molybdenum diselenide has shown promise in photocatalysis, particularly in the degradation of pollutants and water treatment. The ultrathin nanosheets of this material, when combined with its inherent semiconductor properties, can act as efficient photocatalysts, harnessing sunlight to drive chemical reactions.

Lastly, MoSe2 has found applications in optomechanics and photonics, thanks to its strong optical properties and piezoelectric behavior. The superfine powder version can be integrated into micro-optical devices, where its tunable refractive index and mechanical response are advantageous.

In summary, CAS 12058-18-3 MoSe2 powder, with its superfine 325 mesh particle size, offers a versatile range of properties that make it an essential material in various sectors. From electronics and energy storage to environmental remediation and photonics, its unique characteristics contribute to the development of innovative technologies and solutions. As research continues to uncover new potential uses, the demand for this high-quality MoSe2 powder is expected to grow in the coming years.

(CAS 12058-18-3 Superfine 325 Mesh Molybdenum Diselenide Powder MoSe2 Powder)

FAQs of CAS 12058-18-3 Superfine 325 Mesh Molybdenum Diselenide Powder MoSe2 Powder

Inquiry us