Overview of Best 20-63um Plasma Spheroidization Refractory Metal molybdenum Powder for 3D printing

Metal powder is a common form of metal that has been processed into fine particles, ranging from a few micrometers to over 100 microns in diameter. It plays a crucial role in various industrial applications due to its unique properties and versatility.

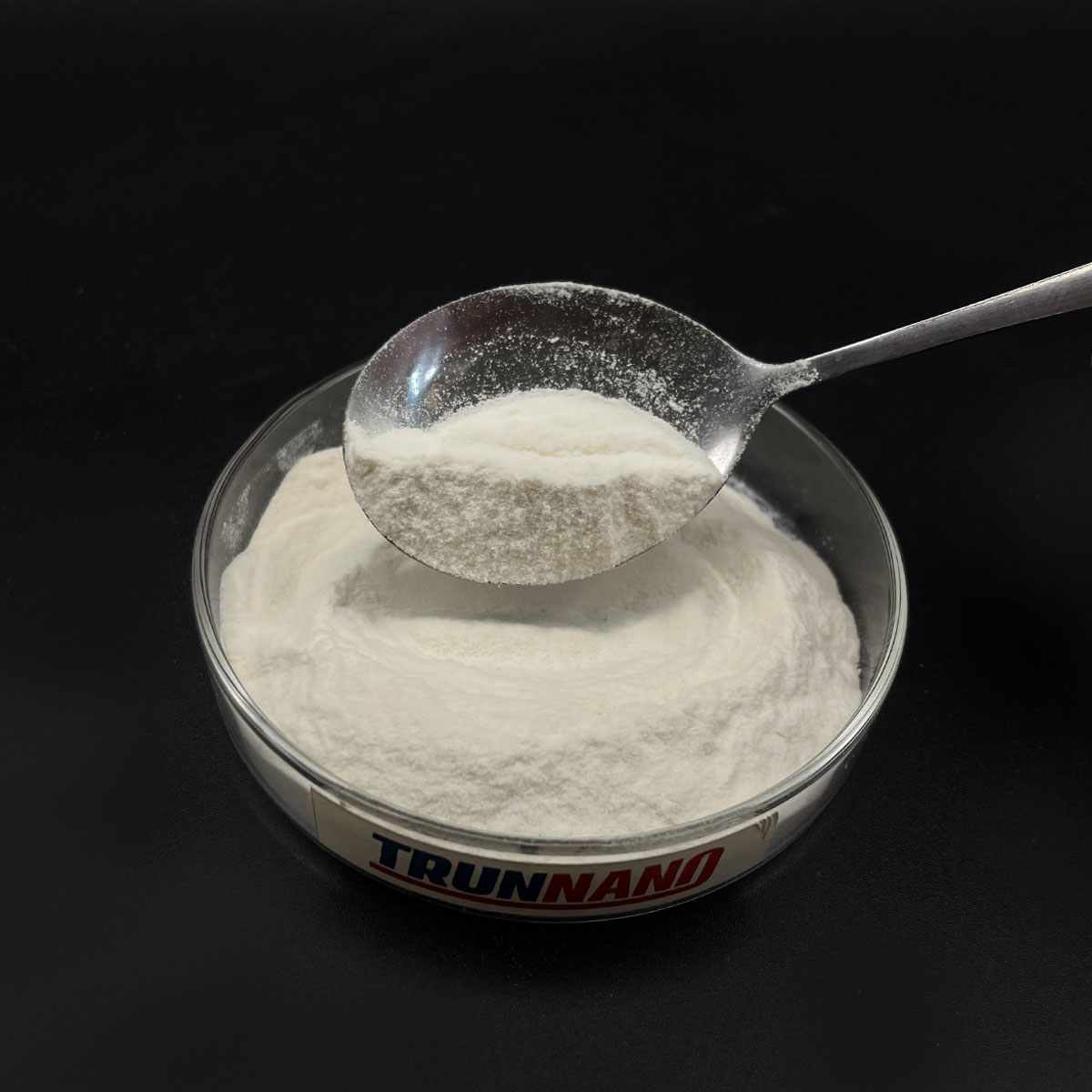

Features of Best 20-63um Plasma Spheroidization Refractory Metal molybdenum Powder for 3D printing

Physical Characteristics

Particle Size: Ranging from nanometers to hundreds of micrometers, the size distribution significantly influences the powder’s flowability, packing density, and sintering behavior.

Shape: Particles can be spherical, irregular, flake-like, or dendritic, each shape affecting the final product’s mechanical properties and surface finish.

Purity: Depending on the production method, metal powders can achieve high levels of purity, critical for applications like electronics and aerospace where impurities can degrade performance.

Density: While less dense than their solid counterparts due to the presence of air between particles, metal powders can be densely packed during processing to approach the density of the solid metal.

Chemical Properties

Reactivity: Some metal powders, particularly aluminum and titanium, are highly reactive with air and moisture, necessitating careful handling and storage under inert atmospheres or vacuum.

Oxidation: Exposure to air can lead to surface oxidation, forming a passive layer that affects sintering and other processes. This can be managed through surface treatment or use of protective atmospheres.

(Best 20-63um Plasma Spheroidization Refractory Metal molybdenum Powder for 3D printing)

Parameters of Best 20-63um Plasma Spheroidization Refractory Metal molybdenum Powder for 3D printing

Title: Optimizing Molybdenum Plasma Spheroidization for Enhanced 3D Printing: A Comprehensive Guide

Introduction:

In the realm of advanced materials and additive manufacturing, the use of high-quality plasma spheroidized molybdenum (Mo) powders plays a pivotal role in achieving exceptional 3D printed parts with enhanced mechanical properties. This article delves into the best parameters for a 20-63um Mo powder specifically tailored for 3D printing applications, providing a detailed overview without any specific formatting.

1. Particle Size Distribution:

A key factor for successful 3D printing is a consistent particle size distribution. The 20-63um range ensures that the Mo particles are within an optimal size for both proper bonding during fusion and efficient layer-by-layer deposition. A narrow size distribution (ideally below 10%) promotes better part integrity and fewer defects.

2. Particle Shape:

Plasma spheroidization process results in spherical particles, which are crucial for achieving a uniform melt pool during extrusion. Spherical particles promote better flowability, minimizing layer lines and ensuring a smoother surface finish. High-quality Mo powders should exhibit a minimum sphericity index of 0.9 or above.

3. Chemical Purity:

The purity of the molybdenum powder directly affects the printed part’s performance. Opt for a high-purity (99.95% or higher) Mo powder to minimize impurities that could lead to porosity, corrosion, or reduced strength. Conducting elemental analysis and ensuring trace elements are below industry standards is essential.

4. Surface Finish:

A clean, smooth surface on the Mo particles enhances printability by reducing adhesion issues and facilitating better layer bonding. After plasma spheroidization, the powder should have a low roughness value (RMS < 0.5 microns) for optimal results.

5. Flowability:

For efficient feeding during the extrusion process, the Mo powder must exhibit good flow characteristics. A low angle of repose (AOR) between 25-35 degrees ensures easy handling and prevents clogging in the printer's nozzle. The powder's bulk density should be around 3.2-3.5 g/cm³ for optimal flow.

6. Thermal Properties:

Molybdenum has a high melting point (2625°C), making it suitable for high-temperature applications. However, for 3D printing, the powder should have a lower onset of sintering to prevent premature bonding. The thermal conductivity and latent heat of fusion should be carefully selected to ensure optimal part formation.

7. Densification and Sintering Behavior:

During printing, the Mo powder should exhibit good densification upon sintering. The powder's sintering kinetics should match the printer's operating temperature to achieve full densification post-printing. A controlled sintering rate ensures minimal shrinkage and distortion.

8. Compatibility with Binder Materials:

The Mo powder should be compatible with commonly used binder materials like PA (polyamide) or PBF (powder bed fusion) resins. Ensure compatibility through compatibility tests to prevent reactions that could affect the final part's properties.

9. Post-Processing Treatments:

After printing, the sintering process may require specific annealing treatments to optimize mechanical properties. These treatments can include furnace heating, stress relief, and grain refinement to enhance the strength and ductility of the printed Mo components.

Conclusion:

Selecting the right 20-63um plasma spheroidized molybdenum powder for 3D printing requires a balance of particle size, shape, purity, and thermal properties. By focusing on these parameters, manufacturers can achieve high-quality, strong, and functional parts in various industries, such as aerospace, automotive, and energy. Regular testing and optimization will further refine the process and unlock the full potential of this refractory metal in additive manufacturing.

(Best 20-63um Plasma Spheroidization Refractory Metal molybdenum Powder for 3D printing)

FAQs of Best 20-63um Plasma Spheroidization Refractory Metal molybdenum Powder for 3D printing

Inquiry us